Large diameter aluminum tubes are widely used for their lightweight, high strength, and corrosion resistance.

They meet the demands of high pressure, temperature, and extreme conditions, enhancing the safety and stability of structures in aerospace, construction, shipbuilding, and energy pipelines.

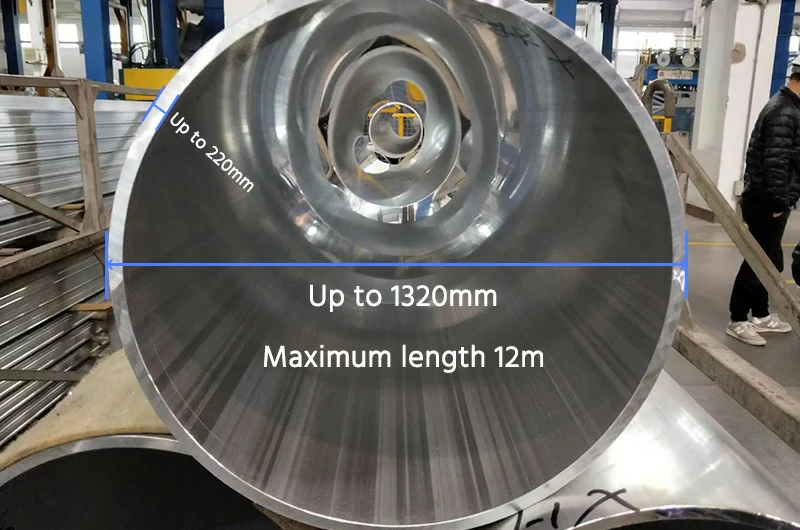

Size range of large diameter aluminum tubes

- Diameter: up to 1600mm

- Wall thickness: 0.5-50mm

- Length: customizable and cut to requirements

- Process: reverse extrusion, vertical extrusion, forging, spiral welded tubes

Specifications of large diameter aluminum tubes

- Standards: ASTM B221, ASTM B429, EN755, AMS-WW-T-700-3A, MIL-A-8625, GJB 2379A, GB/T6893, YS/T479

- China Aluminum Corporation holds ISO 9001, GJB 9001, and AS9100 international quality certifications, as well as Nadcap accreditation, ensuring products undergo strict non-destructive testing, thermal inspection, and material analysis.

Popular large diameter aluminum tube products

Chalco supports customization of performance and dimensions of large aluminum tubes according to customer requirements, ensuring excellent surface quality, dimensional accuracy, and material performance.

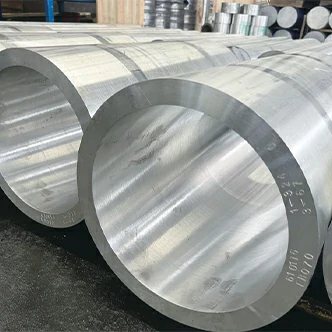

Large diameter forged tubes

Large diameter forged tubes offer exceptional high strength, pressure resistance, and high-temperature durability, with uniform internal structure.

Their dimensions are highly customizable, making them ideal for use in high-pressure, extreme temperature, and complex mechanical stress environments.

-

Large diameter forged tubes for power applications

Alloy: 6061-T6

Dimensions: 334mm x 284mm x 690mm

Electrical conductivity: >53% IACA

-

Large diameter forged tubes for hydrogen cylinders

Alloy: 6061 H112

Dimensions: 490mm x 840mm

Tolerance: -0.5mm to +2.5mm

Straightness: ≤1mm

-

Large diameter forged tubes for marine applications

Alloy:5083 H112

Dimensions: 504mm x 459mm x 2000mm

Straightness: ≤1mm

-

Forged tubes for pressure vessels

Alloy: 5083 H112

Dimensions: 424mm x 29mm x 2200mm

Eccentricity: ≤1.0mm

Straightness: ≤1mm

-

5A06-O large diameter forged tube

Dimensions: 388mm x 356mm x 470mm

-

5083 H112 large diameter forged tube

Dimensions: 524mm x 481mm x 1988mm

-

7A19 T6 large diameter forged tube

Dimensions: 556mm x 438mm x 1680mm

-

6061 T6 large diameter forged tubes

Dimensions:710mm x 630mm x 2420mm, 834mm x 778mm x 1665mm

-

Large diameter T-shaped forged tube

Alloy: 6061-T6

Dimensions: 960mm x 780mm x 2150mm

-

Large diameter mirror-finish support rod forged tube

Alloy: 2A12-T352

Specification: Custom fabrication (made to drawings)

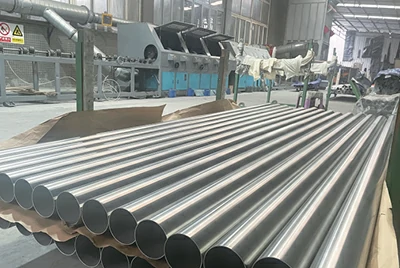

Large diameter high-precision, high-surface-quality tubes

These tubes offer exceptional dimensional accuracy and surface finish, while also providing high strength and pressure resistance, making them suitable for harsh environments and high-precision applications.

6005 large diameter high-precision, high-surface-quality tubes

Dimensions:90mm x 3.5mm x 1600mm, 115mm x 3.5mm x 1600mm

Tolerance:±0.05mm

Surface roughness Ra: 0.4 μm

5A02 large diameter high-precision, high-surface-quality tube

Dimensions:90mm x 1.5mm x 3000mm

Tolerance: ±0.05mm

Surface roughness Ra:0.4 μm

5083 large diameter high-precision, high-surface-quality tube

Dimensions: 166mm x 3mm x 1900mm

Tolerance: ±0.05mm

Surface roughness Ra: 0.4 μm

Large diameter thin-walled tubes

Large diameter thin-walled tubes achieve thin wall thickness and high precision while ensuring strength and pressure resistance.

They are widely used in aerospace, automotive manufacturing, heat exchange equipment, and precision industries.

2A12-T4 large diameter high-precision thin-walled tube

Excellent strength, corrosion resistance, and dimensional accuracy.

Standard: GB/T6893-2010 High-precision grade

-

6061-T4 large diameter high-precision thin-walled tube

Dimensions: 76.2mm x 0.89mm x 3000mm

-

5083-O large diameter high-precision thin-walled tube

Dimensions: 219mm x 3mm x 3000mm

Large diameter high-precision thin-walled tube has strict tolerances:

| Dimensions | Outer diameter tolerance | Wall thickness tolerance | Straightness | Ovality |

| 98mm*2mm*1500mm | ±0.1mm | ±0.2mm | ≤0.3mm | - |

| 78mm*2mm*2000mm | ±0.1mm | ±0.2mm | ≤0.3mm | - |

| 109mm*4mm*1000mm | +0.2mm | - | ≤0.5mm | - |

| 118mm*2mm*1100mm | +0.2mm | +0.2mm | ≤0.5mm | - |

| 127mm*2mm*2900mm | ±0.15mm | ±0.1mm | ≤0.5mm | ≤0.2mm |

| 165mm*2mm*7000mm | ±0.2mm | ±0.15mm | ≤2mm |

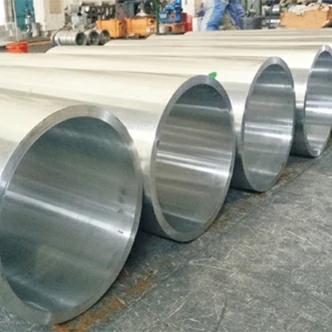

Large diameter seamless aluminum tubes

Seamless extruded aluminum tubes are lightweight, strong, and corrosion-resistant, ideal for gas storage, air separation, and hydrogen fuel.

Large diameter seamless aluminum tubes

Alloys:2024, 5052, 6061, 7075

Outer diameter:50-1600mm

Contact us now

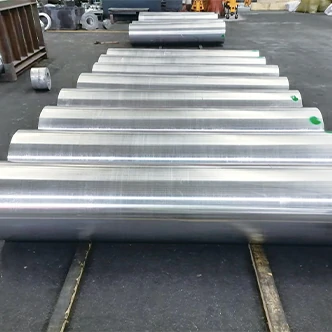

Large diameter spiral welded pipes

Large diameter spiral welded pipes, with a maximum diameter of 1580mm, are made using advanced low-temperature welding technology.

They offer flexible dimensions, high material efficiency, and fast production, making them ideal for oil and gas transport and infrastructure.

Alloys:5052, 5754, 5083, 5A05

Technology: Low-temperature spiral seam welding

Diameter: 219-1580mm

Wall thickness:4.0-14mm

Contact us now

Large diameter conduits

Popular size chart for large diameter conduits:

| Product | Size | Standard | Customizable |

| 5A06 large diameter conduit | 165mm*2.5mm*4000mm | GJB 2379A-2015 | Dimensions, performance, tolerance |

| 5A06 large diameter conduit | 180mm*5.0mm*3000mm | GJB 2379A-2015 | Dimensions, performance, tolerance |

| 5A06 large diameter conduit | 256mm*2.0mm*3000mm | GJB 2379A-2015 | Dimensions, performance, tolerance |

| 6061 large diameter conduit | 110mm*2.0mm*3000mm | GJB 2379A-2015 | Dimensions, performance, tolerance |

Large diameter reducer pipes

Large diameter reducer pipes and thickness transition pipes offer flexible size and wall thickness adjustments.

Large diameter reducer pipes

Large end diameter: 25-450mm

Small end diameter: 15-400mm

Wall thickness: 1.0-15mm

Contact us now

Large diameter thickness transition pipes

Large end wall thickness: 12-200mm

Small end wall thickness: 2-15mm

Contact us nowLarge diameter custom-shaped tubes

Large diameter custom-shaped tubes offer highly customized services to meet customers' needs for unique sizes and shapes.

Large diameter teardrop-shaped oval tube

Alloy:2024-T3

Major axis: 196.85mm

Minor axis: 83.56mm

Standard:: AMS-WW-T-700-3A

Large diameter high-precision ribbed tube

Alloy: 6061-T6

Dimensions:155mm x 2.5mm x 3000mm

Wall thickness tolerance:2.5±0.15mm

Large diameter conical tube

Alloy:5A06-O

Dimensionss: 150mm x 10mm – 200mm x 10mm

Applications: Military weapon components

Large diameter bent tube

Alloy: 2A12-O

Size range:34mm x 4mm, 50mm x 5mm, 90mm x 5mm

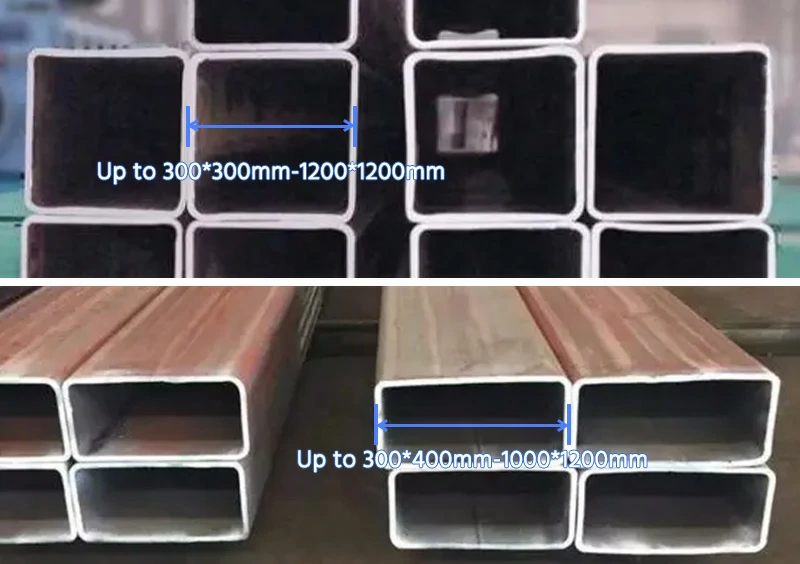

Large diameter rectangular tube

Alloy:5A06-O

Dimensions:300mm x 120mm x 6mm

Application:Missile brackets for warships

Contact us now

Chalco full range of large diameter aluminum tube size chart

Chalco offers a full range of large diameter aluminum tubes, covering various size ranges to meet diverse customization needs.

Large diameter round tube size range

| Product | Alloy | Diameter (mm) | Wall thickness (mm) |

| Large diameter thin-walled round tube | 1xxx – 8xxx | 5-450 | 0.5-15 |

| Large diameter thick-walled round tube | 1xxx – 8xxx | 50-620 | 10-50 |

| Aerospace round conduit | 5A02, 5A03, 5A06, 6061 | 6-300 | 0.5-5 |

Large diameter rectangular tube size range

| Product | Alloy | Side length (mm) | Wall thickness (mm) |

| Square tube | 1xxx – 8xxx | 10-320 | 0.5-20 |

| Rectangular tube | 1xxx – 8xxx | 10-380 (long side), 10-250 (short side) | 0.5-20 |

Large diameter reducer pipe size range

| Product | Alloy | Side length (mm) | Wall thickness (mm) |

| Square tube | 1xxx – 8xxx | 10-320 | 0.5-20 |

| Rectangular tube | 1xxx – 8xxx | 10-380 (long side), 10-250 (short side) | 0.5-20 |

Large diameter thickness transition pipe size range

| Product | Alloy | Large end wall thickness (mm) | Small end wall thickness (mm) |

| Thickness transition pipe (wall thickness transition pipe) | 1xxx – 8xxx | 12-200 | 2-15 |

Large diameter special tubes

| Product | Alloy | Outer diameter (mm) | Wall thickness (mm) |

| Large diameter teardrop tube | 2xxx – 7xxx | 350 max | 1.0-15 |

| Large diameter high surface thin-walled tube | 2xxx – 7xxx | 300 max | 0.5-5.0 |

| Large diameter reverse extrusion tube | 1xxx – 8xxx | 150-735 | - |

| Large diameter forged tube | 1xxx – 8xxx | 500-1200 | - |

| Large diameter seamless tube | 1xxx – 7xxx | 1600 max | - |

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

Common alloys for large diameter aluminum tubes

Large diameter aluminum tubes are widely used in industrial production, and different alloys exhibit significant differences in performance.

| Alloy series | Properties | Main applications |

| 1050 1060 1070 1000 | High purity, good conductivity and thermal conductivity, good plasticity, good corrosion resistance | Food, chemical, electronics industries |

| 2024 2A12 | High strength, corrosion-resistant, aerospace-grade aluminum | Aerospace, military structural components |

| 3003 | Higher strength than 1000 series, good corrosion resistance, excellent weldability | Pressure vessels, storage tanks, heat exchangers |

| 5052 5083 5754 5A06 | High strength, excellent corrosion resistance, especially seawater resistance | Shipbuilding, chemical equipment, aerospace |

| 6061 6063 6082 6005 6005A | Excellent overall performance, high strength, good plasticity, good weldability | Construction, transportation, machinery manufacturing |

| 7075 7001 7003 7005 | Extremely high strength, high hardness, good wear resistance, but poor plasticity | Aerospace, military, high-strength structural components |

Applications of large diameter aluminum tubes

- High-speed trains and bullet trains: Used for body structures and connectors to reduce weight and improve energy efficiency.

- Shipbuilding: Used as frame structures and pipeline materials to reduce corrosion.

- Submarines and aircraft carriers: Used for pressure vessels and structural supports to enhance pressure resistance and reduce weight.

- Aircraft manufacturing: Used for fuselage frames and fuel systems to reduce aircraft weight.

- Defense and military: Used for radar antennas, electronic device cooling, and missile structural components to improve performance and mobility.

- Energy and infrastructure: Used for oil and gas pipelines, high-pressure vessels, and high-speed rail track supports, providing corrosion resistance and lightweight solutions.

- Construction industry: Used for building structures and ship hulls to improve durability and reduce weight.

- Production capacity: The production capacity of large diameter aluminum tubes is an important indicator of a company's technical strength.

Chalco customizes large diameter aluminum tubes based on your application

- Size customization: Precisely customize the outer diameter, wall thickness, and length of the aluminum tube according to your specific requirements.

- Performance customization: Adjust the mechanical properties of the aluminum tube, such as strength, hardness, and corrosion resistance, by selecting appropriate alloys and heat treatment processes to meet the performance standards for specific applications.

- Shape customization: In addition to standard round tubes, we can customize square tubes, oval tubes, and other special shapes to suit different design and functional requirements.

- Alloy selection: We offer a variety of aluminum alloy grades, including commonly used 2024, 6061, 7075, to meet different environmental and strength needs.

- Custom according to drawing: We accept customer-provided drawings for precise production, ensuring the product exactly matches the design.

With rich experience and advanced production technology, Chalco can meet all your customization needs for large diameter aluminum tubes, ensuring product quality and performance meet the highest standards.Quick Quote

Surface treatments for large diameter aluminum tubes

Chalco offers a variety of surface treatment options for your large diameter aluminum tubes, including:

- Mill Finish: The aluminum tube is untreated, offering low cost and suitability for further processing.

- Anodizing: Enhances corrosion resistance and provides a range of color options.

- Powder Coating: Available in various colors and textures, with excellent weather resistance.

- Electrophoretic Coating: Ensures uniform coating with consistent appearance.

- Fluorocarbon Coating: Offers excellent weather resistance, ideal for outdoor environments.

We offer professional surface treatments for large diameter aluminum tubes, ensuring custom sizes, corrosion resistance, and quality control to meet industry needs.

How Chalco produces large diameter aluminum tubes

Seamless reverse extrusion technology for large diameter aluminum tubes

Our company uses a 10, 000-ton extrusion machine and reverse extrusion technology to produce high-precision, high-strength large diameter seamless aluminum tubes.

This technology ensures more uniform metal flow during extrusion, resulting in denser material structure and more stable performance.

Large diameter spiral welded tube technology

We also use advanced spiral welding technology, capable of producing large diameter aluminum welded tubes with diameters up to 1600mm.

This technology is ideal for special projects that require larger tube diameters, offering high reliability and lower cost.

Large diameter forged aluminum tube technology

Chalco uses 10, 000-ton ultra-large free forging equipment to manufacture large diameter aluminum tubes, commonly using medium to high-strength alloys such as 6061, 6082, and 7075, offering excellent strength and toughness.

This process does not require molds, providing greater customization flexibility to meet various requirements for tube dimensions, wall thickness, and length.

Large diameter aluminum tube vertical extrusion technology

Chalco's patented vertical extrusion technology breaks through the limitations of traditional processes, enabling the production of large diameter seamless aluminum tubes while overcoming the length constraints of forging processes.

Using a 500MN extrusion machine for billet perforation and vertical pressing, the entire extrusion process takes only 10 minutes, significantly reducing production time.

The advanced shaft furnace heat treatment system ensures a temperature deviation of less than ±5°C during heating, with the holding process deviation within ±5°C.

Large diameter aluminum tube quality inspection – ensuring superior performance and reliability

- Surface inspection: Ensures the tube surface is smooth and free from visible defects such as scratches, cracks, bubbles, etc.

- Dimensional accuracy: Precise measurement of inner diameter, outer diameter, wall thickness, and length using calipers, micrometers, and other precision instruments, ensuring dimensions are within specified tolerances.

- Straightness and roundness: Checks the tube's straightness and roundness to ensure uniform wall thickness and compliance with design requirements.

- Ultrasonic testing: Detects internal defects like cracks and voids using ultrasonic testing.

- Metallographic examination: Observes grain size and distribution under a metallographic microscope to ensure uniform material structure.

- Mechanical property testing: Measures tensile strength, yield strength, and elongation using a tensile testing machine.

- Hardness testing: Measures material hardness using a hardness tester to ensure it meets the required standards.

- Pressure testing: Applies internal pressure to the tube to test its pressure resistance.

Large Diameter Aluminum Tube Packaging and Transportation

Proper packaging and protection measures are essential when transporting large diameter aluminum tubes to ensure that the products are not damaged during transit.

- Custom Wooden Pallets or Steel Frame Supports: Based on the size and weight of the aluminum tubes, custom wooden pallets or steel frames are used to securely stabilize the tubes during transportation, preventing deformation or damage.

- Protective Material Wrapping: The surface of the aluminum tubes is wrapped in protective films, foam, or other materials to prevent scratches, collisions, and corrosion.

- Wooden Box Packaging: For high-precision tubes or those requiring higher levels of protection, wooden box packaging is used to provide comprehensive protection.

- Reinforced Bundling: Steel straps or ropes are used to securely fasten the aluminum tubes to pallets or supports, preventing sliding or shifting during transportation.

- Specialized Transport Equipment: Based on the size and weight of the aluminum tubes, appropriate transportation tools, such as large trucks or containers, are selected.

Common Questions About Large Diameter Aluminum Tubes

Question: Can you process large diameter aluminum tubes?

Answer: Yes, we offer CNC processing services and can customize according to your requirements. Whether it's size processing, bending, or assembly, we provide one-stop services for you.

Question: What is the minimum order quantity (MOQ)?

Answer: The minimum order quantity is 1 piece. The larger the quantity, the more competitive the unit price will be.

Question: How to get an accurate quote?

Answer: Please provide the following product information: including length, diameter, wall thickness, color, surface treatment, process requirements, cross-sectional drawings with dimension details, aluminum alloy type, temper, dimensional tolerances, key dimensions, and inspection standards.

Question: How long does it take to prepare samples of large diameter aluminum tubes?

Answer: If the sample size is in stock, it usually takes 7-10 days to complete. For custom orders, it typically takes 25-35 days, as extrusion tools need to be produced and custom processing is required.

Other Popular Large-Size Products from Chalco

Chalco not only holds a leading position in the field of large diameter aluminum tubes but also offers a variety of large-size products to meet the diverse needs of customers.

Φ500-1000mm Large Diameter Aluminum Pipe

Exclusive Technique for Large Diameter Al Pipe

Large Diameter Aluminum Pipe

Extra-Large Seamless Aluminum Tubes

Large diameter Aluminum Square & Rectangular Tube

Large Diameter Aluminum Billet Bar

Ultra-Thick Aluminum Plate

Large Custom Aluminum Extrusions

Large Diameter Aluminum Rolled Ring Forging