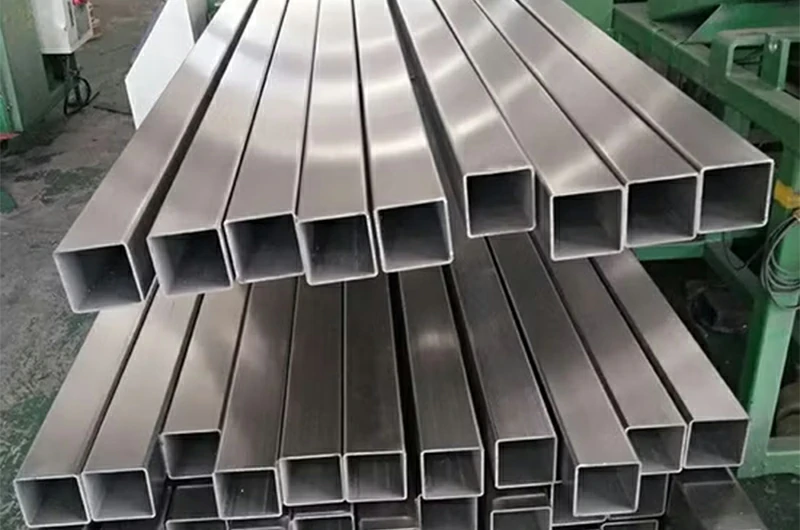

Chalco offers high-strength rectangular tubes with the largest outer diameter, highest precision, and excellent surface quality.

We customize sizes and performance for aerospace, defense, marine, and automotive industries.

Specifications of high precision high strength rectangular tubes

Standards: ASTM B221, ASTM B308/B308M, EN 755, GB/T6893-2010

Certifications: ISO 9001, AS9100, MIL-STD-1916, MIL-A-46027, AMS 4183, RoHS, CE

Classification Society Certifications: LR, CCS, SCV, KR

Popular products of high precision high strength rectangular tubes

High precision high strength seamless square tube

Alloy:0.2mm-200mm

Size:25mm*25mm*1.5mm

Side length range:10-320mm

Wall thickness range:0.5-20mm

Contact us now

Tensile strength: 315 MPa

Yield strength: 145 MPa

Elongation: 15%

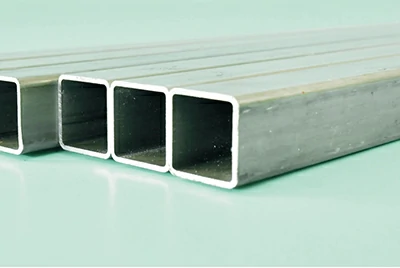

High precision high strength seamless rectangular tube

Long side dimension range: 10-380mm

Short side dimension range: 10-250mm

Tensile strength: 410-420 MPa

Yield strength: 225-275 MPa

Elongation: 13%

High precision high strength seamless aluminum flat tube

Tensile strength: 315 MPa

Yield strength: 145 MPa

Elongation: 15%

Integral square tube with end caps

Integral square tube with end caps size chart:

| Size | Side length | Length | Inner diameter tolerance |

| 27mm*27mm*195mm | 27mm | 195mm | +0.2mm |

| 28mm*28mm*195mm | 28mm | 195mm | +0.2mm |

| 29mm*29mm*195mm | 29mm | 195mm | +0.2mm |

| 30mm*30mm*195mm | 30mm | 195mm | +0.2mm |

High precision high strength large size rectangular tube

Extra-large square tube sizes: 300×300mm - 1200×1200mm

Extra-large rectangular tube sizes: 300×400mm - 1000×1200mm

Wall thickness: 6-120mm

Standards: Customized according to customer requirements

High precision high strength rectangular tube performance

We offer customized high precision high strength rectangular tubes to meet your alloy, size, and performance (tensile strength, yield strength, elongation) requirements. Quick Quote

| Alloy | Temper | Tensile strength | Yield strength | Elongation |

| 1100 | O | 70-105 Mpa | - | 20% |

| 2A12 | O | 245 | - | 10% |

| 2A12 | T4 | 410-420 | 225-275 | 13 |

| 2024 | O | 240 | 140 | 12 |

| 2024 | T4 | 440 | 290 | 12 |

| 3003 | O | 95-130 | 35 | 25 |

| 3003 | H14 | 130-165 | 110 | 6 |

| 5A06 | O | 315 | 145 | 15 |

| 5083 | O | 270-350 | 110 | 16 |

| 5083 | H32 | 280 | 200 | 6 |

| 6061 | O | 150 | 110 | 16 |

| 6061 | T4 | 205 | 110 | 16 |

| 6061 | T6 | 290 | 240 | 10 |

| 6063 | O | 130 | - | 20 |

| 6063 | T6 | 220 | 190 | 10 |

| 7A04 | O | 265 | - | 8 |

| 7020 | T6 | 350 | 280 | 10 |

| 8A06 | O H14 | 100-120 | - | 20 |

Advantages of high precision high strength rectangular tubes

- High precision and low tolerance: High precision rectangular tubes ensure accuracy in length, width, and wall thickness.

- Strong load-bearing capacity: High strength rectangular tubes can withstand greater external pressure and loads.

- Excellent fatigue resistance: High strength rectangular tubes have excellent fatigue resistance, effectively resisting damage from repeated loading.

- High surface finish: Rectangular tubes with high surface quality typically have a very smooth and uniform surface, with no obvious defects.

- Corrosion and oxidation resistance: High strength and high surface quality rectangular tubes are enhanced with corrosion and oxidation resistance through surface treatment or alloying.

- Uniform stress distribution: High precision rectangular tubes distribute stress more evenly when subjected to forces.

Applications of high precision high strength rectangular tubes

- Hydraulic cylinders and pressure vessels: Used in applications that withstand high pressure and stringent forming requirements, ensuring the tubes have high strength and a uniform surface.

- Aerospace: Used for structural components and support frames in aircraft and spacecraft, requiring high strength and precision.

- Automotive industry: Used in vehicle body frames and load-bearing parts, requiring high strength and excellent surface quality to enhance safety and appearance.

- Construction and engineering: Used in building support frames, curtain walls, etc., providing strength and stability while reducing weight.

- Machinery manufacturing: Applied in precision machinery to improve the overall performance and operational stability of the structure.

- Electrical and electronic equipment: Used for enclosures, brackets, etc., with corrosion resistance, high precision, and excellent surface treatment.

- Camera lens interfaces: Suitable for lightweight and durable camera supports, ensuring high precision and corrosion resistance.

- Marine fittings: Due to strong corrosion resistance, widely used in ship brackets, railings, and other parts in marine environments.

- Door and window frames, and reinforcement structures: Used in high-strength door and window frames and building structures, providing stability and an attractive surface.

Surface treatments of high precision high strength rectangular tubes

- Mill Finish: The original surface treatment, maintaining the natural shine and texture of the aluminum.

- Anodizing: Increases surface hardness, enhances corrosion resistance, and offers color options.

- Powder Coating: Provides a thick protective layer, resistant to corrosion, UV, and comes in various colors.

- Electrophoretic Coating: Improves corrosion resistance, with an even coating that is wear-resistant and UV-resistant.

- PVDF Coating: Extremely high corrosion resistance, UV-resistant, and durable for long-lasting aesthetics.

Processing of high precision high strength rectangular tubes

According to specific application requirements, Chalco offers one-stop processing for high precision high strength aluminum rectangular tubes:

Cutting aluminum rectangular tubes

We provide precise cutting services, capable of cutting aluminum rectangular tubes to various lengths according to your needs, ensuring smooth and even cuts.

Drilling aluminum rectangular tubes

We offer accurate drilling services, suitable for aluminum rectangular tubes that require hole placements, widely used in assembly, fastening, and other applications.

Welding aluminum rectangular tubes

We can perform welding on aluminum rectangular tubes based on customer requirements, ensuring the strength and stability of the connection, ideal for the assembly of structural components.

Bending aluminum rectangular tubes

We provide precise bending services for aluminum rectangular tubes, suitable for applications requiring specific angles or shapes.

Quality inspection of high precision high strength rectangular tubes

- Surface inspection: Ensures the tube surface is smooth, with no visible defects such as scratches, cracks, bubbles, etc.

- Dimensional accuracy: Uses precision instruments such as vernier calipers and micrometers to measure the inner diameter, outer diameter, wall thickness, and length, ensuring dimensions are within specified tolerance ranges.

- Straightness and torsion: Checks the straightness and torsion of the tube to meet design requirements.

- Ultrasonic testing: Detects internal defects such as cracks, pores, etc., using ultrasonic waves.

- Metallographic inspection: Observes grain size and distribution under a metallographic microscope to ensure uniform material structure.

- Mechanical property testing: Measures tensile strength, yield strength, and elongation using a tensile testing machine.

- Hardness testing: Uses a hardness tester to measure material hardness, ensuring it meets usage requirements.

- Pressure testing: Applies internal pressure to the tube to test its pressure resistance capability.

Common alloys for high precision high strength rectangular tubes

1100 rectangular tube

Although the tensile strength of 1100 alloy is relatively low, it has good formability, corrosion resistance, and excellent surface quality.

2A12 rectangular tube

2A12 alloy offers high strength and good machinability, making it suitable for high-precision, high-strength applications in the aerospace industry. However, additional surface treatment is needed to enhance corrosion resistance.

2024 rectangular tube

2024 alloy is known for its high strength and good fatigue resistance, making it ideal for aerospace and aviation applications.

Its high precision rectangular tubes have excellent mechanical properties, suitable for applications that require handling heavy loads.

3003 rectangular tube

3003 alloy is a commonly used aluminum alloy with good corrosion resistance. Although its strength is relatively low, its excellent corrosion resistance and formability make it ideal for products that require high surface quality and lightweight design.

5A06 rectangular tube

5A06 alloy has good corrosion resistance and high strength, widely used in marine environments and the transportation industry.

Its surface quality and strength make it suitable for high-demand structural applications.

5083 rectangular tube

5083 alloy is an aluminum alloy with extremely high corrosion resistance, especially suitable for applications in shipbuilding, marine environments, and other harsh conditions.

Its high strength and good surface treatment performance make it an ideal choice for high-end structural components.

6061 rectangular tube

6061 alloy is one of the most commonly used engineering aluminum alloys, offering good strength, weldability, and corrosion resistance. It is suitable for structural applications and high-precision requirements.

In T6 temper, 6061 alloy offers very high strength, making it suitable for high-strength, high-precision rectangular tube applications.

7075 rectangular tube

7075 alloy excels in high strength, high precision, and high corrosion resistance, making it an ideal choice for applications requiring extreme strength and durability.

It is suited for high-performance and demanding environments.

How to manufacture high strength high precision aluminum rectangular tubes?

Using advanced precision extrusion technology, aluminum tubes are formed uniformly under high temperatures, ensuring the production of high-strength aluminum rectangular tubes.

By precisely controlling temperature and pressure, we ensure that each aluminum tube meets high standards for tensile strength and yield strength.

A fine cooling system is used to maintain the surface finish of the tubes while preventing internal stress, ensuring both high strength and high precision.

Our mold designs are carefully calculated to ensure that each mold maintains precision during production, significantly reducing errors.

We use high-hardness, wear-resistant materials to manufacture molds, extending mold life while ensuring consistent dimensions and shapes of the aluminum tubes.

During the design and use of molds, special surface treatment techniques are employed to reduce frictional wear, preventing scratches on the surface of the aluminum tubes and keeping them smooth and flawless.

Transportation and packaging of high strength high precision aluminum rectangular tubes

- Protective film: Wraps the surface of the aluminum tubes to prevent scratches and damage.

- Wooden crates or pallets: Sturdy outer packaging ensures the aluminum tubes are stable and secure.

- Foam protection: Uses foam lining for fragile aluminum tubes to increase impact resistance.

- Strapping and securing: Uses steel bands or plastic straps to secure the tubes and prevent movement.

- Clear labeling: Product information is clearly marked on the packaging for easy management and transportation.

Custom packaging, such as moisture-proof or shock-resistant packaging, is available upon request.

Shipping method (sea, air, or land transport) is selected based on tube quantity and destination to ensure timely delivery.

Common questions when purchasing high strength high precision aluminum rectangular tubes

Q: I need aluminum tubes that can withstand heavy loads. How can I ensure the strength is sufficient?

A: We use high-quality aluminum alloys (such as 6061, 7075, etc.) and employ precise extrusion processes with strict quality control. All products undergo mechanical property testing to ensure they meet the strength requirements for your projects.

Q: What is the dimensional tolerance of the high precision aluminum rectangular tubes? Will they meet my specifications?

A: Our aluminum rectangular tubes are produced using high-precision CNC equipment and precision molds. Dimensional tolerances are strictly controlled within international standards. Whether it's wall thickness, length, or width, we provide stable and consistent precision to meet your engineering needs.

Q: Will the aluminum rectangular tubes' surfaces have scratches, oxide layers, or other defects?

A: We use fine surface treatment technologies to ensure a smooth and flawless surface. Additionally, during transportation and processing, we apply protective films and packaging to minimize surface damage.

Q: The price of high strength high precision aluminum rectangular tubes seems higher than standard aluminum tubes. Is it worth purchasing?

A: While the price of high strength high precision aluminum rectangular tubes is relatively higher, their excellent performance (such as strong corrosion resistance, high precision, and long service life) offers great efficiency and long-term cost savings for your project, making it a worthwhile investment. We offer competitive pricing and high-quality after-sales service to ensure you get value for your purchase.

Q: I need the aluminum rectangular tubes urgently. Can the delivery time meet my requirements?

A: Depending on the order quantity and customization requirements, the delivery time is typically 1-3 weeks. We will also provide timely progress updates to ensure on-time delivery.

Q: My project requires specific specifications for aluminum rectangular tubes. Can you provide customization?

A: We offer comprehensive customization services. Whether it's size, material, surface treatment, or special performance requirements, we can provide tailored aluminum rectangular tube products according to your needs.