Chalco provides coated aluminum with new high-performance hydrophilic paint for air conditioning manufacturing and processing enterprises, as well as manufacturers of aluminum fins for heat exchangers.

The aluminum substrate is covered with highly innovative hydrophilic paint, specially developed to enhance corrosion resistance and limit condensation.Welcome contact

Specification of Chalco hydrophilic lacquered aluminum foil

| Alloy | 1100, 1200, 1030, 3003, 3102, 8006, 8011, 8021 |

| Temper | O H22 H24 H26 |

| Width | 60mm-1440mm |

| Thickness | 0.006-0.3mm |

| Coil inner diameter | 76mm, 152mm, out coil diameter according to the customer requirement |

| Color | Pure, Blue, Gold, Black, White |

| Specification | ASTM B479 ASTM B117 JIS H4160 DIN1784 The hydrophilic aluminum foil used for air conditioners should comply with YS/T95.2-2001. |

Hot selling aluminum alloy series of hydrophilic lacquered aluminum foil

-

8011 H16 hydrophilic lacquered aluminum foil

For the refrigerant pipes in the air conditioning system and the casing of the outdoor air conditioning unit.

-

1100/1200 O H11 hydrophilic lacquered aluminum foil

Good processability and corrosion resistance, suitable for applications such as air conditioning, heat exchangers, and evaporators.

-

1030B H22 hydrophilic lacquered aluminum foil

Manufacturing of fins for air conditioning systems and industrial radiators. Improve water droplet diffusion and optimize heat exchange performance.

-

3102 H24 hydrophilic lacquered aluminum foil

Used for heating fins for air conditioning systems possess good hydrophilicity and heat dissipation effects.

-

8006 H26 hydrophilic lacquered aluminum foil

It has good hydrophilicity and is suitable for improving the heat exchange efficiency of air conditioning systems.

-

3003 hydrophilic lacquered aluminum foil

Used for hydrophilic fins in air conditioning systems to optimize heat exchange performance.

| Mechanical Properties of Common Aluminum Foil for Hydrophilic Foil | ||||

| Alloy-Temper | Thickness Range (mm) | Tensile Strength (MPa) | Elongation (%) | Cupping Test Value (mm) |

| 1030B H26, 3102 H26 | 0.085-0.09 | 130-140 | ≥13 | ≥5.2 |

| 1030B H26, 3102 H26 | 0.091-0.12 | 130-140 | ≥15 | ≥5.5 |

| 8011-O | 0.10-0.15 | 110-122 | ≥23 | ≥6.0 |

| 0.151-0.25 | 110-122 | ≥25 | ≥6.5 | |

| 8011 H22 | 0.08-0.09 | 115-125 | ≥20 | ≥6.5 |

| 0.091-0.15 | 115-125 | ≥22 | ≥6.0 | |

| 0.151-0.2 | 115-125 | ≥25 | ≥6.5 | |

| 8011 H24 | 0.09-0.2 | 120-135 | ≥22 | ≥6.0 |

Chalco hot selling hydrophilic aluminum foil products

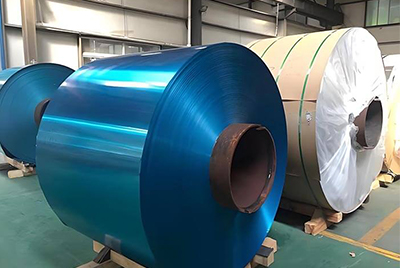

Blue hydrophilic aluminum foilQuick Quote

Many air conditioning fins now come with blue, green, or golden corrosion-resistant coatings to enhance both their corrosion resistance and aesthetic appeal. Chalco can provide customized corrosion-resistant coatings in various colors according to customer requirements.

Hydrophilic aluminum finsQuick Quote

Fins for heat dissipation systems improve heat exchange performance by enhancing surface wetting through hydrophilic properties.

Hydrophilic foil for air conditionersQuick Quote

Hydrophilic foil finds widespread use in air conditioning, commonly in components like air coolers and condensers.

Hydrophilic foil for radiatorsQuick Quote

Used for the surface of radiators, to improve wettability and enhance heat dissipation performance.

Hydrophilic foil for evaporatorsQuick Quote

For the application demands of evaporators, it is often used in evaporator coils to improve the diffusion of water droplets and promote evaporation.

The production and structure of hydrophilic foil

Hydrophilic aluminum foil is a special type of aluminum foil that has been treated to have a hydrophilic (water-absorbing) surface. The production process of hydrophilic foil typically involves the following steps:

Raw foil → cleaning → coating (hydrophilic layer, corrosion-resistant layer) → drying and curing → cutting → final hydrophilic foil product.

The finished product encompasses the following structure:

- Substrate aluminum foil: the core material is standard aluminum foil, typically made from high-quality pure aluminum and rolled into thin sheets.

- Hydrophilic coating: hydrophilic properties are achieved by applying a specialized coating on one or both sides of the aluminum foil.

- Surface treatment: hydrophilic coatings are usually applied through chemical or electrochemical processes to make them more attractive to water molecules.

- Microstructure: hydrophilic treatment alters the surface of the aluminum foil, reducing its contact angle with water droplets. This means that water droplets will spread and form a thin film on the surface rather than forming droplets.

Performance parameters and product features of Chalco hydrophilic foil

| Coating thickness | 1.0~3.0μm (The average thickness of single side) |

| Hydrophilia | The initial hydrophilic angle≤5; Continuous hydrophilic angle≤25 |

| Adhesive force | Cupping Test (pressure deep 5mm): no flaking. Grid experiment (100/100): no delaminating. |

| Corrosion resistance | Salt fog test (72 Hours) R.N≥9.5 |

| Alkali resistance | With 20 degree centigrade, soak in the 20%NaOH with 3 Minutes, the sample coating layer totally no frothing. |

| Solvent resistance | Weight loss of Sample≤1% |

| Heat resistance | Under 200℃, keep for 5 minute, properties and the color remains the same; Under 300℃, keep for 5 minutes, coating layer just become light yellow. |

| Oil resistivity | In the volatile oil soaked for 24 hours, coating layer has no frothing |

- Hydrophilic aluminum foil enhances air conditioning efficiency by promoting the spread of water droplets during condensation, reducing electricity consumption.

- After undergoing degreasing, washing, and drying processes, it exhibits excellent hydrophilicity and corrosion resistance, extending the lifespan of air conditioning units.

- Hydrophilic aluminum foil improves cooling efficiency by 5%, has anti-corrosion properties, is odorless, and prevents water droplet buildup, optimizing air conditioning performance.

Hydrophilic coating specifications of Chalco hydrophilic foil

| Categories | Common hydrophilic foil | Self-lubricating hydrophilic foil | High resistance hydrophilic foil |

| Color | Light blue, light gold, dark blue, deep gold | Light blue | Gold |

| Film Weight (g/m²) | 1.7-4.0 | 1.8-2.8 | 2.6-3.8 |

| Original Hydrophilic Diameter | ≥9.0mm | - | - |

| Initial Hydrophilic Angle | ≤10° | - | - |

| Remain Hydrophilic Angle | ≤26° | - | - |

| Adhesion Requirement | Cupping Test (5mm press): No delamination | T Bending Test (180° bend): No delamination or peeling | |

| Corrosion Resistance Test Conditions | 500h continuous neutral salt spray | - | |

| Corrosion Resistance Requirement | R.N-O ≥9.5 | - |

Transparent (Silver) Hydrophilic Aluminum Foil

- Features: Maintains the original metallic luster of aluminum foil with a transparent coating, providing basic hydrophilic properties.

- Applications: Suitable for standard air conditioning systems where appearance is not a priority.

- Advantages: Cost-effective and ideal for mass production of standard products.

Blue Hydrophilic Aluminum Foil

- Features: Offers excellent hydrophilic properties, enabling rapid dispersion of condensation water and preventing water droplet accumulation, which can affect heat exchange efficiency.

- Applications: Widely used in air conditioning evaporators, suitable for household and commercial air conditioners.

- Advantages: Aesthetic blue coating provides additional corrosion resistance.

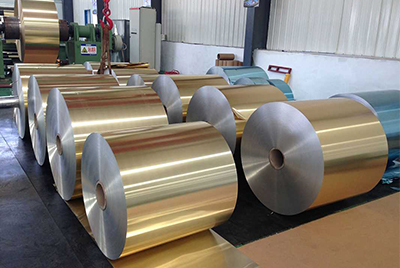

Gold Hydrophilic Aluminum Foil

- Features: Coating offers superior corrosion resistance, making it suitable for use in demanding environments such as high humidity and high salt spray conditions.

- Applications: Commonly used in condensers or heat exchangers of high-end air conditioning systems.

- Advantages: Premium gold appearance enhances the product's high-end appeal and durability.

Hydrophilic foil purchasing guide

1. Cores and Roll Diameter of Chalco hydrophilic foil| Core I/D | I/D Tolerance | Wall Thickness | Roll O/D (mm) |

| Steel core 76.2mm | ±0.5mm | 2mm | 350-550mm |

| Alu core 76.2mm | ±0.5mm | 4mm | 350-550mm |

| Steel core 152.4mm | ±0.5mm | 3mm | 450-1100mm |

| Alu core 152.4mm | ±0.5mm | 4.5mm | 450-1100mm |

| Paper core 152.4mm | ±0.5mm | 13-17mm | 450-1100mm |

2. Dimensions and Tolerances

- Thickness Tolerance: ±3%

- Width Tolerance: ±1.0mm

- Special tolerance requirements for thickness and width can be customized according to customer needs.

3. Surface Quality

- The surface color of the aluminum foil should be uniform and free from defects that affect usage, such as coating voids, wrinkles, stripes, color differences, scratches, inclusions, and corrosion.

- End Quality: The aluminum foil end face should be tightly and evenly rolled, with no cracks, burrs, or other defects, with overlapping layers ≤2mm and tower shape ≤5mm.

- Joints: Joint rate should not exceed 20%, and joints should be clearly marked.

4. Product Labeling

- Roll Label: Each roll should indicate product name, alloy temper, specifications, weight, roll number, number and position of joints, inspector’s stamp, and company name.

- Box Label: Each box should indicate order number, technical agreement, product name, alloy temper, specifications, box number, gross weight, net weight, production date, and joint count.

5. Coating Performance

- Adhesion Requirements: Cupping Test (pressing depth 5mm): No delamination; T-Bend Test (180° bend): No delamination or peeling.

- Corrosion Resistance: Common hydrophilic foil (blue, gold) 500 hours of continuous neutral salt spray test, R.N-O≥9.5; High-resistance hydrophilic foil (gold): 1500 hours of continuous neutral salt spray test, R.N-O≥9.8.

- Acid and Alkaline Resistance: Coating is free from whitening, blistering, swelling, and shedding.

- Heat Resistance: After being held at 200℃ for 10 minutes, the coating adhesion and color remain stable.

- Oil Resistance: After 48 hours of immersion, no blistering or peeling occurs, with initial hydrophilicity θ≤10°.

- Odor: No abnormal odor under room temperature testing or after baking at 140℃ for 10 minutes. No odor in immersion test.

- Harmful Substance Content: Complies with EU REACH and ROHS standards.

6. Packaging, Transport, and Storage

- Packaging: Cores and packaging boxes should be kept clean, and aluminum foil should be sealed in plastic bags to protect against moisture, with a shelf life of 12 months.

- Storage: In accordance with Chinese National Standard GB/T 3199, avoiding moisture and extreme temperatures.

Choose Chalco hydrophilic aluminum foil

Chalco has established long-term partnerships with numerous renowned air conditioning manufacturers, securing a significant share in the air conditioning market.Quick Quote

- Chalco utilizes German machinery to produce Fin Stock aluminum foil, ranging from ingots to coils, with a width up to 1800mm and thickness down to 0.006mm.

- Chalco employs advanced technology to produce aluminum foils meeting EN standards, meticulously controlling production steps and tracing raw material origins.

- All certificates are available, including SGS-ROHS, SGS-REACH, MSDS, FDA, TDS, ISO9001 & ISO14001.

- Our product packaging meets regulations and customer needs, using standard export methods like plastic film or kraft paper wrapping, wooden crates, and clear labeling for safe transportation.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote