Chalco can produce large-size aluminum extrusions with complex shapes in alloys such as 2024, 5083, 6060, 6005, 6061, 6063, 6082, 7075, and 7005, with widths up to 750 mm, wall thickness as thin as 0.3 mm, and lengths up to 26 meters.

This ensures high performance and large cross-sections while achieving integrated extrusion molding.

Specifications for large cross-section and large-size extruded profiles

Standards: EN 755, EN 12020, ASTM B221, ASTM B429, ASTM B308, GJB 367, GB/T 5237

Certifications: IATF 16949, ISO 9001, EN 1508, AS9100, NADCAP

Large cross-section and large-size extruded profile products

- Large-size T-Slot extruded profiles

- Aerospace large cross-section extruded profiles

- Military large cross-section extruded profiles

- Large-size extruded aluminum floor profiles for trailers and trucks

- Large-size water-cooled motor casing profiles

- Large-size aluminum floor extrusions for containers

- Large-diameter seamless aluminum tubes for pressure vessels

- Large cross-section extruded profiles for rail transportation

- Large-size aluminum extrusions for electric vehicle battery trays

- Large-size heat sink extruded profiles

- Large cross-section bridge extruded profiles

- Large-size aluminum formwork for construction

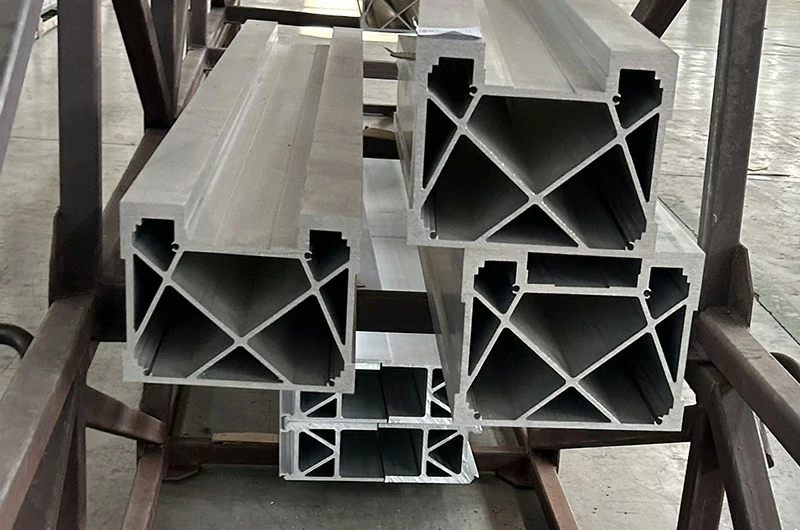

Large-size T-Slot extruded profiles

Alloys: 6061, 6063, 6005

Temper: T5, T6

Popular Sizes: 80x160mm, 100x200mm, 160x160mm, 180x180mm, 200x400mm, 300x300mm

Features: High load-bearing capacity, structural stability, easy assembly, corrosion resistance, customizable

Applications: Frames, workbenches, machine supports, assembly lines, and laboratory equipment

Aerospace large cross-section extruded profiles

In military and aerospace applications, large cross-section aluminum profiles are widely used in various critical components and products due to their excellent mechanical properties and lightweight characteristics.

Alloys: 7050, 7075, 7475, 2024, 6061, 6063

Widths: 100 - 500 mm

Lengths: 6 meters (customizable)

Applications: Fuselage beams and stringers, wing spars, ribs, seat frames

Features: High strength, corrosion resistance, good fatigue resistance, lightweight, capable of withstanding high stresses during flight

Military large cross-section extruded profiles

These large cross-section aluminum profiles enhance the performance, reliability, and lifespan of military equipment. The dimensions and shapes of these profiles can be flexibly adjusted based on specific application needs to ensure optimal structural and functional performance.

Alloys: 2024, 7075, 2A12, 6A02, 7A09, 7A52

Widths: 200 - 400 mm

Thicknesses: 10 - 30 mm

Lengths: 10 meters

Features: High strength, high temperature resistance, fatigue resistance, lightweight

Applications: Missile casings, framework structures and support arms for launchers

Large-size extruded aluminum floor profiles for trailers and trucks

We produce custom interlocking design aluminum floors for trailers.

Alloys: 6082T6, 6061T6, 6063T6, 6005-T6

Width: 750 mm

Length: 25 meters (82 feet)

Applications: The extruded aluminum floors are lightweight and durable, suitable for use in trailers, semi-trailers, box trailers, and truck trailers.

Large-size water-cooled motor casing profiles

As motors are high-speed power-driven devices that generate significant heat, water cooling structures are commonly used for cooling and heat dissipation in motor casings.

Alloys: 6063, 6061

Dimensions: Customizable based on customer requirements

Thermal Conductivity: Up to 218 W/[m·K]

Surface Treatment: Anodizing, powder coating

Features: High strength, excellent heat dissipation, lightweight, good corrosion resistance, outstanding machinability

Applications: Motor casings for textiles, mining, wastewater treatment, and automotive industries

Large-size aluminum floor extrusions for containers

Alloys: 6061-T6, 6082-T6, 6063-T6

Width: 750 mm

Applications: Aluminum extrusions for trailer containers, sea freight containers, refrigerated containers, frozen containers, and storage containers.

Features: Lightweight, corrosion-resistant, easy to form, stable performance at low temperatures, easy to machine

Large-diameter seamless aluminum tubes for pressure vessels

Alloys: 5083, 6061, 6063

Temper: H112, F

Popular Outer Diameters: 270 mm, 304 mm, 360 mm, 370 mm, 375 mm

Maximum Outer Diameter: 600 mm

Process: Reverse extrusion (indirect extrusion)

Surface Treatment: Anodizing (silver, black, brown), Powder coating (RAL colors and metallic finishes)

Advantages: Lightweight, medium strength, high corrosion resistance, no tendency for stress corrosion cracking, good weldability, easy to form

Applications: Hydrogen storage, aircraft fuel tanks, oxygen cylinders, chemical storage tanks, natural gas storage, fire extinguishers

Large cross-section extruded profiles for rail transportation

In the rail transportation sector, particularly in metro and high-speed rail systems, large cross-section aluminum profiles are widely used.

Alloys: 6005A, 6061, 6063, 6082, 7005

Widths: 100 - 550 mm

Lengths: 2 m - 12 m

Features: Lightweight, high strength, corrosion resistance, easy to process

Applications: Car body frames, roofs, sidewalls, chassis, and other critical structural components

Large-size aluminum extrusions for electric vehicle battery trays

We manufacture and assemble aluminum extrusions for electric vehicle battery trays (also known as battery boxes, or battery enclosures).

Alloys: 6061, 6063, 6082, 2024, 5083, 7075

Dimensions: Customized based on new energy vehicle designs

Weight: 40 kg - 150 kg

Advantages: Moderate strength, excellent formability, high corrosion resistance, good heat dissipation, and protection against electromagnetic interference

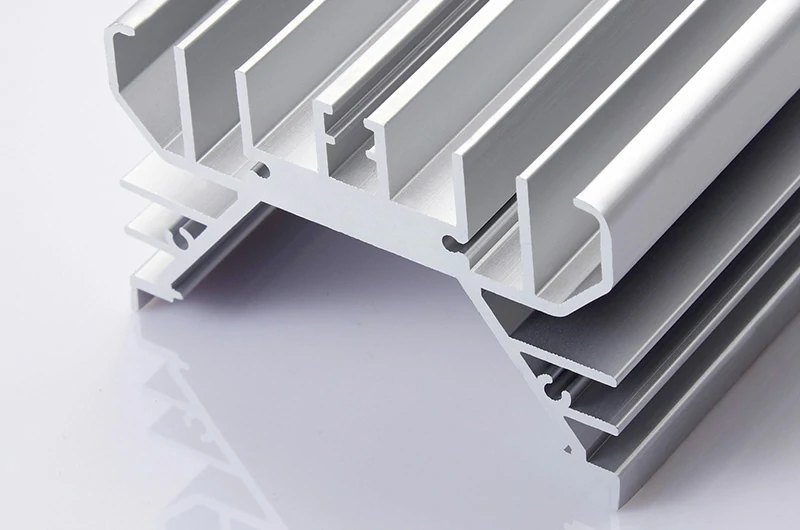

Large-size heat sink extruded profiles

We offer over 1, 000 types of heat sink molds, providing custom extruded heat sink profiles ranging from simple flat fins to complex geometric structures, tailored to your personalized air cooling needs.

Alloys: 6063 / 6061 / 3003

Temper: T5/T6

Surface Treatment: Anodizing (silver, black)

Length: Customized upon request (standard length is 6 meters)

Features: Integral extruded profiles, high fin density, effective heat dissipation

Packaging: Anti-static film and shrink wrap

Large cross-section bridge extruded profiles

Large-size bridge profiles feature anti-slip surface deck plates, made from extruded aluminum with multi-chamber hollow sections joined by Friction Stir Welding (FSW).

Alloys: 5083, 6005, 6061, 6063, 6082, 7005

Widths: 200 mm - 600 mm

Wall Thickness: 5 - 40 mm

Lengths: Customized based on bridge design requirements

Surface Treatment: Anodizing, electrophoretic coating, powder coating

Features: Lightweight, strong, corrosion-resistant, good elasticity, capable of complex shapes, recyclable

Large-size aluminum formwork for construction

Large extruded aluminum formwork profiles can be customized according to project requirements, including special hole designs, connection components, and surface treatments to meet various construction needs.

Alloys: 6061, 6063, 6082, 5052

Common Widths: 400 mm - 600 mm

Lengths: 2 m - 6 m

Shapes: Rectangular, T-shaped, L-shaped, U-shaped

Surface Treatment: Anodizing, powder coating

Key features of large cross-section extruded aluminum profiles

- Thin-Wall Structure: Designed with a special thin-wall approach to provide optimal strength while minimizing material usage.

- Large Cross-Section: Made with wide cross-sectional dimensions to offer strong structural support for various applications.

- Precision Manufacturing: Utilizing advanced technology, our profiles are manufactured with the highest precision, ensuring consistent quality and dimensional accuracy.

- Integrated Molding: Integrated molding offers high strength, production efficiency, material utilization, design flexibility, and cost-effectiveness.

- Lightweight Design: Despite their large cross-sectional area, our aluminum profiles are lightweight, making them easy to handle and install.

- Versatile Applications: Our profiles are suitable for a wide range of industries including construction, transportation, and aerospace, providing versatility and adaptability to meet diverse project needs.

Elevate your projects with our high-quality aluminum profiles, where innovation meets reliability. Experience the difference of precision engineering and unparalleled quality with our thin-wall large cross-section aluminum profiles. Quick Quote

Custom aluminum alloy solutions for complex shapes and large sizes

- Experienced Facility: Our factory specializes in the production of large-size and large-cross-section aluminum profiles, particularly suited for industries such as construction, aerospace, rail transportation, and automotive, which require high-strength and lightweight solutions.

- One-Stop Service: We offer comprehensive services for aluminum profiles, including CNC machining, surface treatments (such as anodizing and powder coating), bending, welding, and assembly.

- Custom Molds: Our production line is capable of customizing various molds to meet customer requirements for complex profile geometries and special-shaped cavities.

- High Precision: We have high-precision manufacturing capabilities and can produce large profiles within strict tolerance ranges to ensure dimensional stability and consistency.

- Small-Batch Production: We support small-batch sample production for customer testing and validation, helping evaluate material performance and suitability.

- Quality Documentation: We provide factory quality certificates and complete traceability documentation for all products, ensuring compliance with industry standards and customer specifications.

- Packaging Options: We offer a range of packaging solutions, allowing customers to choose between standard or customized packaging for the manufactured components.

One-stop welding solutions

- TIG Welding (GTAW) and MIG Welding (GMAW): Suitable for a wide range of aluminum extrusion alloys, particularly 5xxx, 6xxx, and 7xxx series.

- Friction Stir Welding (FSW): We are a global leader in FSW technology, capable of handling large aluminum profiles up to 18 meters in length and 3.5 meters in width.

- Welding Standards: Our welding processes comply with ISO 3834 standards to ensure welding quality.

- Certified Welders: Our welding team is certified under ISO 9606-2 and ISO 14732, with extensive operational experience.

- Advanced Equipment: Equipped with modern welding technology, including IGM welding robots and Fronius and KEMPPI digital welding machines.

- Applications: Suitable for components requiring high compressive strength and sealing properties.