Industry leadership of large diameter aluminum tube pipe

Chalco is a leader in large-diameter aluminum pipe production, utilizing patented vertical extrusion technology. This innovation overcomes the limitations of traditional extrusion methods for achieving larger diameters and forging methods for attaining greater lengths in seamless pipes.

Key product specifications

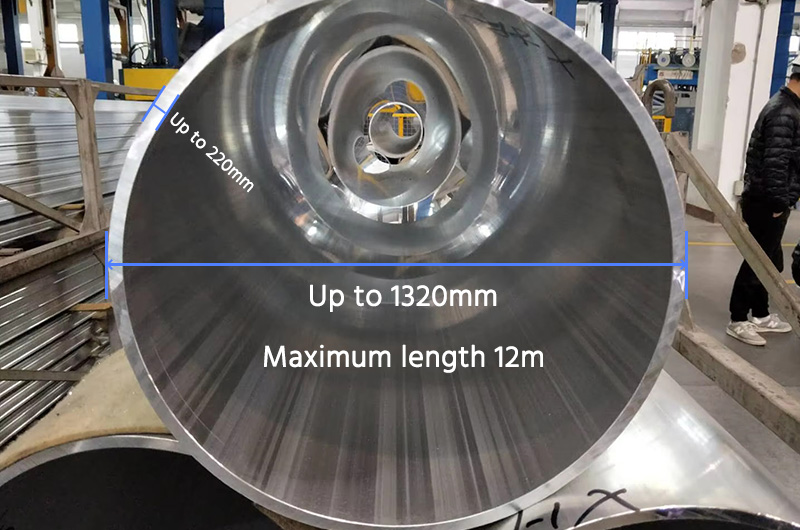

1. Large-Diameter Seamless Pipes [Click to view product details]

- Round Pipes: Diameter up to 1320mm, length up to 13m.

- Square Pipes: Outer dimensions up to 1200x1200mm, length up to 13m.

- Alloy Available: 5A05, 5A06, 5083, 6061, 6063, 6082, 7075, 7055, 7034, 1420, 2195, 2050, 2055...

2. Spiral-Welded Pipes [Click to view product details]

- Round Pipes: Maximum outer diameter of 1528mm.

- Supporting large diameter end bends and other products

- Alloy Available: 5052 5754 5083 5A05...

3. Thin wall large diameter aluminum tube pipe [Click to view product details]

- Maximum Outer Diameter: Up to 540mm (customizable based on specific requirements).

- Wall Thickness: Typically ranges from 2mm to 10mm, depending on the application and alloy.

- Length: Customizable, with standard lengths up to 12 meters, extendable based on project needs.

- Alloys Available: 2024, 5083, 6061, 6063, 7075, 2014, 2219, 3003, 5052, 5086, 6005, 6060...

4. Large diamerer reducer aluminum tube pipe [Click to view product details]

- Large end diameter: 25-450mm

- Small end diameter: 15-400mm

- Wall thickness: 1.0-15mm

5. Additional offerings [Click to view product details]

- Forged Aluminum Pipes: Diameter up to 1000mm.

- Extruded Aluminum Pipes: Diameter up to 500mm.

- Cold-Drawn Pipes: Diameter up to 20mm with high precision.

- Alloys Available: 6061, 6063, 7075, 2024, 5083, and other standard alloys are available in abundant stock.

6. Large diameter aluminum pipe fittings [Click to view product details]

- Aluminum Flanges

- Aluminum Elbows

- Aluminum Tees

- Aluminum Caps

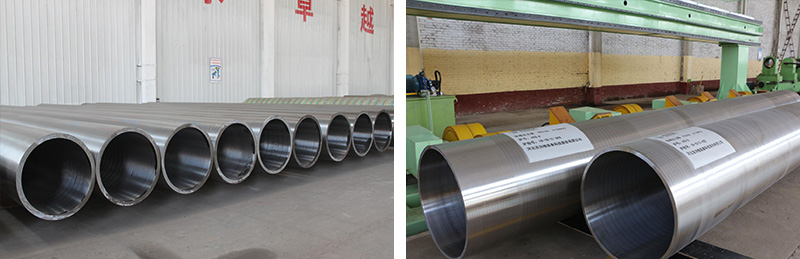

Large diameter seamless aluminum tube pipe supply—Patented Technology (Highly Recommended)

Traditional seamless pipe production typically employs extrusion and drawing processes. Chalco, however, has revolutionized this approach with its 50, 000-ton vertical hot extrusion press, overcoming challenges in manufacturing large-diameter seamless pipes. This advanced equipment facilitates the production of pipes with larger diameters, more flexible wall thicknesses, and extended lengths, while significantly reducing mold costs.

Product display of Chalco seamless aluminum tube and the accessories

- Large-Diameter Seamless Pipes: Custom sizes, up to 1320mm in diameter and 13 meters in length, for large pipeline systems.

- Shaped Pipe Fittings: Custom sizes, processed with a bending machine for uniform diameter and wall thickness.

- Elbow Tee Fittings: Customizable diameter and angle, used for pipe branching and fluid control.

- Valve Bodies: Custom sizes and structures, offering corrosion resistance and lightweight properties for valve systems.

Key technical features and production equipment display

- High Efficiency: Produces a 1320mm-diameter pipe in just a few minutes, achieving exceptional production speed.

- Precision Engineering: Combines advanced mold design and heat treatment to ensure accurate dimensions, superior surface quality, and consistent mechanical properties.

- Advanced Heat Treatment: The online heat treatment system guarantees mechanical consistency and optimal material properties.

- Cost-Effective Design: Patented technologies for machining inner and outer bores lower production costs by reducing mold expenses.

- Non-Destructive Testing: Ensures surface finishes and mechanical performance meet stringent quality standards.

- Global Leadership: Produces seamless pipes with diameters up to 1.32 meters, wall thicknesses of up to 200mm, and lengths of up to 12 meters, filling critical gaps in the whole world.

Large diameter seamless tube application fields

- Nuclear Power: Essential for reactor pump housings, main pipelines, and other critical components, contributing to cost reduction and enhanced efficiency in nuclear power plant construction.

- Shipbuilding: Used for corrosion-resistant marine components, ensuring durability and reliability in harsh marine environments.

- Aerospace: Applied in fuel pipelines and hydraulic systems, meeting the high-performance demands of the aerospace industry.

- Thermal Power: Integral in power generation plants, offering robust and durable solutions for various pipeline needs.

- Petrochemical: Utilized in oil and gas transportation and processing, ensuring the safety and reliability of critical infrastructure.

- Coal Chemical: Important in the coal chemical industry for large-scale processing and transportation systems.

Large diameter spiral welded aluminum tube pipe supply—Patented Technology (Hot Deals)

The maximum diameter of large diameter spiral welded pipes can reach 1580mm. Advanced low-temperature spiral welding production technology is used to weld narrow aluminum plates and strips into large diameter aluminum circular pipes through spiral welding. Flexible size, customizable according to user drawings.

The pressure of Chalco large-diameter spiral welding is designed to be 1.0MPa through the pipeline water injection pressure design of experiments. When the pressure reaches 5.1MPa, the welding seam is intact after blasting from the side of the middle section of the pipeline.Quick Quote

Products and accessories of Chalco large diameter spiral welded aluminum tube pipe

- Large-Diameter Spiral Welded Pipes: Available in alloys like 5052, 5754, 5083, and 5A05, with a maximum outer diameter of 1580mm and customizable lengths, ideal for large-scale pipelines.

- Elbows: Custom elbows produced using spiral welding, available in various sizes and alloys, offering reliable pressure resistance and durability.

- Tee Fittings: Tee fittings in alloys such as 5052 and 5754, designed for branching pipelines, customizable in size and shape.

- Custom Pipe Fittings: Additional fittings like reducers and flanges, made from the same alloys, tailored to specific pipeline needs and pressure requirements.

| Nominal pressure PN≤1.0 MPa | ||||||||||||||

| Nominal diameter DN | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1000 | 1200 | 1300 | 1400 | 1500 |

| OD | 312 | 362 | 412 | 466 | 516 | 630 | 720 | 820 | 920 | 1020 | 1224 | 1324 | 1328 | 1528 |

| WT δ | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 12 | 12 | 12 | 14 | 14 |

| Theoretical weight kg | 187 | 215 | 245.2 | 372.7 | 413.4 | 499.2 | 571.8 | 800 | 912 | 1214 | 1480 | 1573 | 1974 | 2117 |

| The length of welded pipes in this table is 12000 mm The size of aluminum spiral welded pipe can be customized according to user drawings, with a customized unit of mm | ||||||||||||||

Production technology and advantages

- Production Technology: Spiral welding technology uses narrow aluminum strips to create large-diameter pipes, with a design pressure up to 5.1MPa, ensuring strength and weld seam integrity.

- High Strength: The hoop stress is twice the axial stress, ensuring superior structural integrity.

- Cost-Effective Flexibility: Narrow strips allow for the creation of larger pipes, optimizing material use and reducing costs.

- Excellent Formability: Tolerance for straightness is within 1mm/m, and length deviation is less than 0.5‰.

- Extended Length: Pipes can be produced in lengths of 12 to 18 meters, with the potential for unlimited length.

Collaborative Sectors

- Nuclear Power: Used for high-performance pipelines and components in nuclear power plants.

- Shipbuilding: Corrosion-resistant pipes for marine applications, ensuring long-term reliability.

- Aerospace: Strong, durable pipes for fluid transport and structural components in aerospace industries.

- Petrochemical: Essential for oil and gas transportation pipelines, offering leak-resistant solutions.

- Environmental Engineering: Ideal for large-scale applications like ventilation and gas treatment systems.

Thin wall aluminum pipe—large size & high precision

High-precision large-diameter thin-walled tubes are specialized pipes known for their high accuracy and lightweight design, commonly used in fields such as aerospace, automotive, and petrochemicals, where strength and weight are critical. Manufactured with advanced processing techniques, these tubes ensure precise control over outer diameter, inner diameter, and wall thickness tolerances, offering both structural rigidity and significant weight reduction.

| Dimensions of Selected Large-Diameter High-Precision Thin-Walled Tubes | ||||||

| Alloy State | Specification | Standard | Dimensional Tolerance | Wall Thickness Tolerance | Ovality | Straightness |

| 2024 T4 | ∅98mm*2.0mm*1500mm, ∅78mm*2.0mm*2000mm | Bilateral Technical Agreement | Inner Diameter Tolerance ±0.1mm | ±0.2mm | <0.3mm/m | |

| 2024 T4 | ∅127mm*2.0mm*2900mm | Customer Drawing Requirement | Outer Diameter Tolerance ±0.15mm | 2.0±0.1mm | 0.2mm | ≤0.5mm/piece |

| 2024 T4 | ∅109mm*∅105mm*1000mm | Customer Drawing Requirement | Inner and Outer Diameter Tolerance 0~+0.2mm | ≤0.5mm/whole piece | ||

| 2024 T4 | ∅165mm*2.0mm*7000mm | GB/T 6893-2010 High Precision | ±0.15mm | 2mm/m | ||

| 2024 T4 | ∅118mm*2.0mm*1100mm | GB/T 6893-2010 High Precision | ±0.1mm | ≤0.5mm/m (whole length) | ||

| 5083 O | ∅219mm*3.0mm*3000mm | GB/T 6893-2010 High Precision | ||||

Large diameter reducer pipe: high-performance transition solutions

Large diameter reducer pipes connect pipes of different sizes, enabling smooth transitions while minimizing flow resistance and pressure loss. Made from high-quality materials, they offer excellent strength, corrosion resistance, and durability, making them ideal for demanding industrial environments.

Features of Chalco aluminum reducer tube pipe

- Diverse Material Options: Available in carbon steel, stainless steel, alloy steel, and other materials to meet varied industrial needs.

- Precision Manufacturing: Accurate dimensions and smooth transitions reduce turbulence and pressure loss.

- High Durability: Exceptional strength, resistance to pressure, high temperature, and corrosion.

- Customizable Specifications: Compatible with standards like ANSI, DIN, and GB, with options for non-standard sizes.

- Easy Installation: Designed for compatibility, ensuring quick and reliable integration into existing systems.

Applications area of Chalco aluminum reducer tube pipe

- Oil and Gas Industry: Used in pipelines for transporting oil, gas, and in refining equipment for flow regulation.

- Chemical Industry: Ideal for chemical transportation and reaction equipment connections.

- Water Treatment Systems: Common in water supply and wastewater treatment for connecting large and small diameter pipes.

- Power Generation: Utilized in steam pipelines and cooling water systems in power plants.

- Marine and Offshore Engineering: Plays a role in fluid transport and pressure regulation in shipbuilding and offshore platforms.

- Food and Pharmaceutical Industry: Stainless steel reducers are particularly suitable for sanitary fluid systems in food and pharmaceutical processes.

Additional offering of Chalco large diameter aluminum tube pipe

Forged large diameter aluminum pipe tube—up to 1000mm

Alloy: conventional hot selling alloys

Temper: T5 T6 T651 etc.

Good size control and excellent mechanical performance.

Extruded aluminum round/square tubes—up to 500mm

Alloy: conventional hot selling alloys

Temper: O F H14 H16 H18 T5 T6 T651 etc.

Excellent surface quality and good processing performance;

Thick wall large diameter aluminum round pipe supply—up to 250mm

Alloy: 2024 5052 5083 6061 6063 7075 etc.

Used in high-pressure vessels, transporting liquids and gases, power transmission busbars, and related fields.

Large diameter aluminum pipe fittings

Choose Chalco aluminum large diameter tube pipe by alloy grade

-

1000 series

1050, 1060, 1070, 1100 etc

-

2000 series

2024, 2219, 2014 etc

-

3000 series

3003 etc

-

5000 series

5052, 5083, 5754 etc

-

6000 series

6061, 6063, 6082, 6005 etc

-

7000 series

7075, 7001, 7003, 7005 etc

-

Aluminum-Lithium Alloy

2090, 2195, 8090, 2050, 2198

Property referece table of Chalco hot selling large diameter aluminum tube pipe products

| Property | Large diameter spiral welded pipe products | Other aluminum tube performance references table | |||||||

| 5052 | 5754 | 5083 | 5A05 | 2024 | 3003 | 6061 | 6063 | 7075 | |

| Elastic Modulus GPa | 68 | 68 | 68 | - | 71 | 70 | 69 | 68 | 70 |

| Elongation at Break % | 1.1-22 | 2.0-19 | 1.1-17 | - | 4.0-16 | 1.1-28 | 3.4-20 | 7.3-21 | |

| Shear Strength GPa | 120-180 | 120-190 | 170-220 | - | 130-320 | 68-130 | 84-210 | 70-190 | 150-340 |

| Ultimate Tensile Strength Rm/MPa | 170-215 | 190-240 | 275-350 | 270-350 | 200-540 | 110-240 | 130-410 | 110-300 | 240-590 |

| Yield Tensile Strength Rp0.2/MPa | 65 | 80 | 125 | 150 | 100-490 | 40-210 | 76-370 | 49-270 | 120-510 |

| Thermal Conductivity W/m-K | 140 | 130 | 120 | - | 120 | 180 | 170 | 190-220 | 130 |

| Electrical Conductivity Equal Volume IACS | 35% | 33% | 29% | - | 30% | 44% | 43% | 49-58% | 33% |

| Electrical Conductivity: Equal Weight IACS | 120% | 110% | 96% | - | 92% | 140% | 140% | 160-190% | 98% |

Chalco-reliable manufacturer and supplier of large diameter tube pipe

Production capacity guarantee: Chalco's comprehensive production line for aluminum pipes covers melting, rolling, forging, and extrusion, with an advanced low-temperature aluminum alloy spiral welding line for varied capacity and specifications.

Quality assurance: We ensure quality through advanced production lines and strict inspection systems for pressure pipeline components, enhancing project safety and reliability.

Certification system: Chalco holds quality system certifications such as ISO 9001, GJB 9001, AS9100, TS16949, and Nadcap certificates for Non Destructive/Heat/Materials Testing.

Cooperative partners: Chalco's large-diameter aluminum pipes are integral to projects including submarine oil and gas pipelines, international space stations, high-speed railway track supports, and ocean engineering.

Aluminum pipe size chart: Chalco specializes in producing a wide range of popular-sized aluminum tubes. We offer reliable quality and a comprehensive selection to meet various needs.

| Die dimensions | |||

| OD(mm) | WA(mm) | OD(mm) | WA(mm) |

| 210 | 16, 20, 25 | 810 | 22, 32, 46, 55, 65, 85, 90, 100, 110 |

| 260 | 20, 25, 30 | 860 | 46, 55, 65, 85, 100, 120, 140 |

| 310 | 20, 25, 30, 35 | 910 | 32, 46, 55, 65, 80 |

| 360 | 20, 24, 30 | 960 | 32, 46, 55, 65, 85, 90, 100, 110 |

| 410 | 24, 28, 32 | 1010 | 55, 65, 85, 90, 100, 110 |

| 460 | 27, 30, 35, 45 | 1060 | 55, 65, 85, 90, 100, 110, 120, 140 |

| 510 | 26, 33, 38, 45, 50 | 1110 | 55, 65, 85, 90, 100, 110 |

| 560 | 16, 20, 25, 30, 35, 50, 60, 85 | 1160 | 65, 80, 100, 120 |

| 610 | 32, 46, 55, 65, 85, 90, 100, 110 | 1210 | 65, 80, 100, 120, 140 |

| 660 | 38, 48, 65, 85, 90, 100 | 1260 | 30, 35, 45, 55, 65, 85, 100, 120, 140 |

| 710 | 25, 34, 46, 55, 65, 85, 90, 100, 120 | 1320 | 30, 35, 45, 55, 65, 85, 100, 120, 140, 160 |

| 760 | 38, 44, 55, 65 | ||

| Hot selling alloy | Aluminum pipe size dimension |

| 6061-T6/ 6063-T6 | 3/8" SCH 40 (.675 OD X .091W) |

| 6061-T6/ 6063-T6 | 1" SCH 40 (1.315 OD X .133 W) |

| 6061-T6/ 6063-T6 | 1" SCH 40 (1.315 OD X .133 wall) |

| 6061-T6/ 6063-T6 | 1" SCH 80 (1.315 OD X .179 wall) |

| 6061-T6/ 6063-T6 | 1/2" SCH 40 (.840 OD X .109W) |

| 6061-T6/ 6063-T6 | 1/2" SCH 80 (.840 OD X .147W) |

| 6061-T6/ 6063-T6 | 10" SCH 40 (10.75 OD X .365 W) |

| 6061-T6/ 6063-T6 | 1-1/2" SCH 40 (1.90 OD X .145 wall) |

| 6061-T6/ 6063-T6 | 1-1/2" SCH 40 (1.90 OD X .145 wall) |

| 6061-T6/ 6063-T6 | 1-1/2" SCH 80 (1.90 OD X .200 wall) |

| 6061-T6/ 6063-T6 | 1-1/4" SCH 40 (1.660 OD X .140W) |

| 6061-T6/ 6063-T6 | 1-1/4" SCH 40 (1.660 OD X .140W) |

| 6061-T6/ 6063-T6 | 1-1/4" SCH 80 (1.66 OD X .191 wall) |

| 6061-T6/ 6063-T6 | 12" SCH 40 (12.75 OD X .375 wall) |

| 6061-T6/ 6063-T6 | 2" SCH 10 (2.375 OD X .109W) |

| 6061-T6/ 6063-T6 | 2" SCH 40 (2.375 OD X .154W) |

| 6061-T6/ 6063-T6 | 2" SCH 40 (2.375 OD X .154W) |

| 6061-T6/ 6063-T6 | 2" SCH 80 (2.375 OD X .218W) |

| 6061-T6/ 6063-T6 | 2-1/2" SCH 40 (2.875 OD X .203 wall) |

| 6061-T6/ 6063-T6 | 2-1/2" SCH 80 (2.875 OD X .276 wall) |

| 6061-T6/ 6063-T6 | 3" SCH 40 (3.50 OD X .216W) |

| 6061-T6/ 6063-T6 | 3" SCH 80 (3.50 OD X .300W) |

| 6061-T6/ 6063-T6 | 3/4" SCH 40 (1.05 OD X .113W) |

| 6061-T6/ 6063-T6 | 3/4" SCH 40 (1.05 OD X .113W) |

| 6061-T6/ 6063-T6 | 3/4" SCH 80 (1.05 OD X .154W) |

| 6061-T6/ 6063-T6 | 3-1/2" SCH 40 (4.00 OD X .226W) |

| 6061-T6/ 6063-T6 | 3-1/2" SCH 80 (4.00 OD X .318W) |

| 6061-T6/ 6063-T6 | 4" SCH 40 (4.50 OD X .237W) |

| 6061-T6/ 6063-T6 | 4" SCH 80 (4.50 OD X .337 wall) |

| 6061-T6/ 6063-T6 | 5" SCH 40 (5.563 OD X .258 W) |

| 6061-T6/ 6063-T6 | 5" SCH 80 (5.563 OD X .375 W) |

| 6061-T6/ 6063-T6 | 6" SCH 40 (6.625 OD X .280W) |

| 6061-T6/ 6063-T6 | 6" SCH 80 (6.625 OD X .432W) |

| 6061-T6/ 6063-T6 | 10" SCH 40 |

| 6061-T6/ 6063-T6 | 10" SCH 80 |

Other large size aluminum products in Chalco

With its strong production and R&D capabilities, Chalco also offers a wide range of large-sized products. Feel free to inquire for more details.Quick Quote

Ultra wide aluminum plate coil

Ultra large diameter aluminum bar

Spiral welding aluminum tube pipe

500-1000mm aluminum tube pipe

Why more and more industries choose to use Chalco large diameter aluminum tube pipe?

- Efficient water distribution, sewage systems, and energy transmission

- Environmental sustainability and infrastructure resilience

- Reliable and cost-effective for a range of industrial applications

- Designed for high-volume flow applications and pressurized ratings

- High resistance to corrosion, wear and tear

- Fast and efficient installation methods both on- and offshore

Choosing guaidance for large diameter tube pipe-The comparasion of large-diameter aluminum pipes, large-diameter steel pipes, and large-diameter HDPE pipes

Large-diameter aluminum pipes, large-diameter steel pipes, and large-diameter HDPE pipes each have unique characteristics and advantages.

Large-diameter aluminum pipes are renowned for their lightweight, excellent corrosion resistance, and high flexibility, making them ideal for aerospace, lightweight structures, and decorative applications, particularly where low-corrosion environments and weight limitations are key considerations.

Large-diameter steel pipes are known for their high strength, weldability, and exceptional resistance to wear. They are primarily used in construction, transportation pipelines, and marine engineering, where they can withstand high pressure and harsh environments, providing long-term stability and corrosion resistance.

Large-diameter HDPE pipes are favored for their superior corrosion resistance, flexibility, and cost-effectiveness. They find wide applications in municipal engineering, industrial pipelines, and agricultural irrigation, especially suitable for applications requiring flexible installation and less stringent weight requirements. Choosing the appropriate pipe material should consider specific environmental requirements such as corrosion resistance, strength needs, cost-effectiveness, and installation flexibility.

| Characteristics / Advantages | Large-Diameter Aluminum Pipes | Large-Diameter Steel Pipes | Large-Diameter HDPE Pipes |

| Material | Lightweight, corrosion-resistant, easy to process | High strength, weldable, high wear resistance | Corrosion-resistant, flexible, abrasion-resistant |

| Strength | Medium | Very high | High |

| Corrosion Resistance | Excellent | Excellent | Excellent |

| Weight | Light | Heavy | Light |

| Flexibility | High | Low | High |

| Installation and Maintenance Cost | Low | High | Low |

| Heat Resistance | Medium | Very high | Medium |

| Cold Resistance | Medium | Medium | Excellent |

| Environmental Impact | Recyclable, environmentally friendly | Recyclable, environmentally friendly | Recyclable, environmentally friendly |

| Cost | Medium | High | Low |

| Applications | Aerospace, lightweight structures, decoration | Construction, transportation pipelines, marine engineering | Municipal engineering, industrial pipelines, agricultural irrigation |

| Suitable Environments | Low-corrosion environments, lightweight structures | High-strength requirements, corrosive environments | Corrosion resistance, flexibility requirements |

| Installation Flexibility | Bendable, easy to process | Rigid, requires welding | Flexible, meets various pipeline layout needs |

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote