Aluminum tubes are an ideal choice for oxygen concentrators due to their light weight, high strength, corrosion resistance and good thermal conductivity. They can stably transmit oxygen at medium and low pressures, prevent contamination and leakage, and are easy to customize.

Chalco 5083, 5052, 6061, 6063 aluminum tubes are manufactured through precision extrusion technology and are widely used in key parts such as cylinders, double cylinders, adsorption towers, radiators, condensers, etc. of household, portable, medical, industrial and special environment oxygen concentrators. Ensure efficient operation and long-term reliability of equipment.

Chalco oxygen generator aluminum tube product introduction

Alloy: 5083, 5052, 6061, 6063

Size range: outer diameter: 12-500mm; wall thickness 2-50mm; length 6000mm, custom cutting;

Surface treatment: anodizing

Additional services: cutting, bending, welding

Chalco aluminum tube—meet the diverse needs of various oxygen concentrators

Home oxygen concentrator

Alloy: 6061-T6

The aluminum tubes of home oxygen concentrators need to be strong while remaining lightweight for easy daily use and movement.

Portable oxygen concentrator

Alloy: 6061-T6, 3003

Portable oxygen concentrators emphasize lightness and portability, so the design of the aluminum tube must take into account both lightness and sufficient strength to withstand pressure.

Industrial oxygen generator

Alloy: 5083, 6061, 6063

Industrial oxygen concentrators need to handle higher oxygen flows and greater pressures, so aluminum tubes require greater strength and durability.

Medical oxygen concentrator

Alloy: 5052, 6061, 6063

Medical oxygen concentrators require higher safety and stability, and aluminum tubes must have better corrosion resistance and pressure resistance to ensure the reliability of the equipment.

Chalco oxygen concentrator aluminum tube hot selling products

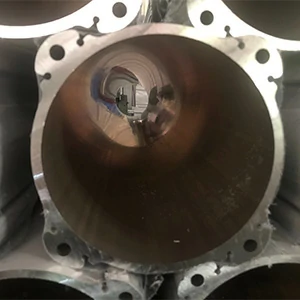

Oxygen generator cylinder tube

It is a key component for storing and transmitting oxygen. It is usually made of high-strength and corrosion-resistant aluminum alloys, such as 6061-T6 or 5052-H32. The aluminum tube has good sealing and pressure resistance, ensuring the stable storage and output of oxygen in the cylinder.

Oxygen generator double tube

This tube is usually used in oxygen concentrators with double-cylinder structures, which can handle two air flows at the same time. The aluminum alloys used, such as 6061 or 6063, are lightweight and corrosion-resistant, ensuring the high efficiency and long-term stable operation of the equipment.

Oxygen generator adsorption tower aluminum tube and accessories

It is used in the adsorption separation device of oxygen generators, and usually need to have high pressure resistance and excellent corrosion resistance. The use of 5083 or 5052 aluminum can maintain structural stability under high pressure conditions, ensuring safety.

Oxygen generator radiator, condenser aluminum tube

It is an important component for condensing and liquefying oxygen in the oxygen concentrator. Made of corrosion-resistant and thermally conductive aluminum alloys such as 5052 or 6061 to ensure that the oxygen remains pure during the condensation process.

Oxygen generator tube end cap

Aluminum tube end caps are used to seal the ends of aluminum tubes to ensure air tightness and prevent oxygen leakage. They are usually made of 6061 or 5052 aluminum alloy, which has high strength and good processability, and can be precisely processed and installed according to equipment requirements.

Chalco oxygen generator aluminum tube production capacity

Chalco has strong capabilities in the production of aluminum tubes for oxygen concentrators and is able to produce aluminum tubes of various specifications and diameters. Qualified aluminum tubes with diameters ranging from smaller specifications to larger diameters are suitable for different models of oxygen concentrators.

- Wide range of sizes: Aluminum tubes of various diameters can be produced according to customer needs to meet the requirements of different application scenarios.

- High quality control: Using advanced production technology and strict quality control standards to ensure that each aluminum tube meets high performance requirements, especially in the medical field, to ensure the reliability and safety of the product.

- Diversified needs: Chalco aluminum tubes provide surface treatments such as anodizing, and can provide bending, cutting and other processing. Can provide supporting facilities such as bending tubes and end caps.

- Large-scale production capabilities: Chalco has the ability to produce on a large scale to meet the needs of large-volume orders while maintaining an efficient production rhythm and fast delivery cycle.

- Technical support: Chalco has rich technical experience and a professional team, able to provide customers with customized solutions and support the production of aluminum tubes with special specifications or requirements.