Chalco forged ring product specifications

Conventional maximum diameter: outer diameter of quenched parts≤2500mm, outer diameter of non-quenched parts≤ 4000mm ;

Patented technology maximum outer diameter: with an outer diameter of up to 10m;

Wall thickness: It has the ability to open molds; wall thickness and wall thickness tolerance can be customized according to customer requirements;

Forging production lines: 3 forging production lines, 1500 tons, 1000 tons, 630 tons, 160 tons presses

Specification: AMS4311F ASTM-B247-15 ASTM-B594 CLASS A, UNE-EN 573-3 UNE-EN 10204

Service area: high-speed trains, radar, oil transportation, aircraft carriers, missiles, weapons, spacecraft, and space stations; widely used in both the national economy and defense industries. Click to match your [industry]

Chalco rolled forging rings hot selling alloy

6061 T6 T652 forged ring roll

It has good weldability and mechanical properties and good corrosion resistance. Suitable for applications requiring high strength and durability, such as aircraft structural parts, spacecraft components, transportation equipment, etc.

Contact us now

7075 T6 T652 T73 T7352 forged ring roll

High strength, good corrosion resistance, excellent tensile resistance and fatigue resistance. Suitable for aerospace and military applications with high performance requirements, such as aircraft fuselage structures, engine parts

Contact us now2024 forged ring roll

It has good strength and processing properties, and has high hardness after heat treatment. Suitable for applications requiring high strength and durability, such as manufacturing aircraft wings, aerospace engine parts, etc.

Contact us now

2219 T6 T852 forged ring roll

Excellent high temperature strength and corrosion resistance. Suitable for high temperature and pressure applications in the aerospace field, such as liquid rocket combustion chambers, rocket engine parts, etc.

Contact us now2014 T4 T6 T652 forged ring roll

Excellent processing performance and fatigue resistance. Chalco 2014 alloy can also be made into triangular forged rings, which are suitable for aerospace, automotive industry that require high strength and durability.

Contact us now

7475 forged ring roll

High strength, good corrosion resistance, excellent tensile resistance and fatigue resistance. Suitable for high performance requirements in aerospace and military fields, such as aircraft structural parts, wings, etc.

Contact us now5083 O H111 H112 forged ring roll

Has excellent corrosion resistance and weldability. Suitable for marine engineering, shipbuilding and other fields that require high corrosion resistance. Such as ship hull structural parts, offshore platforms, LNG tanks, etc.

Contact us now

7050 T74 T7452 forged ring roll

Has high strength and excellent fatigue resistance. Suitable for high-performance requirements in the aerospace field, such as aircraft fuselage structures, wings, etc.

Contact us nowIn addition to the above-mentioned hot-selling alloy products, Chalco can also produce and process other aluminum alloy forged rings. If you have needs, you can check the alloy table and contact us by email. Quick Quote

| Alloy | Supply temper | |

| Die forgings | Free forging | |

| 1100 | H112 | |

| 2025 | T6 | T6, T652 |

| 3003 | H112 | |

| 4032 | T6 | |

| 6066 | T6 | |

| 6151 | T6 | |

| 7049 | T73 | T73, T7352 |

| 7175 | T74, T7452, T7454 | T74, T7452 |

Chalco forged ring selling products

Seamless rolled forged ringsQuick Quote

Adopted to continuously forge the metal blank into a ring shape at high temperature without cutting or welding, ensuring the continuity, uniformity and integrity of the ring. The uniform structure and high strength provide more reliable performance and longer service life.

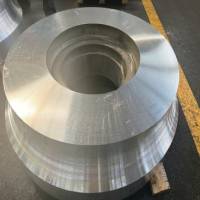

Thick-walled forged ring (Ø1900mm x Ø1200mm x 85mm)Quick Quote

The popular thick-walled forged ring, made from 7075 T6 alloy, features tensile strength of ≥530MPa, yield strength of ≥450MPa, and elongation of ≥8%. Its strength and durability make it ideal for high-stress applications, commonly used in aerospace, defense, and heavy machinery.

Tapered forged ringQuick Quote

Usually made from 6061 T6, has dimensions of Ø2080mm x Ø1829mm x 1020mm and features a tensile strength of ≥320MPa, yield strength of ≥270MPa, and elongation of ≥10%. Its robust mechanical properties make it ideal for demanding applications, such as specific naval engineering projects.

Special shaped forging ringQuick Quote

Usually made from 6061 T6 alloy, has dimensions of Ø1090mm x Ø374mm x 330mm. With its high strength and versatility, this forged part is suitable for specialized applications in industries requiring tailored, high-performance components, such as aerospace and heavy machinery.

D-shaped forged ring or Forged triangular ringQuick Quote

Durable, high-strength and have good sealing performance, and are suitable for connection and sealing in high-pressure and heavy-load environments. Commonly used in pipe connections, sealing of valves and pumps, ships and pressure vessels, etc.

Forged flangeQuick Quote

Forged part used to connect pipes and pipe fittings. It is mainly used in petroleum, chemical industry, electric power and other industries. Forged flanges have the advantages of high connection strength, good sealing, and strong corrosion resistance.

Forged wheelsQuick Quote

Automobile wheels made by forging technology. They have the advantages of high strength, light weight, good heat dissipation and good wear resistance. The price of forged wheels is higher than that of cast wheels, but their performance is better, so they are mainly used in high-end cars.

Chalco large diameter forged ring processing methods and production capabilities

| Open die forging ring | Closed die forging ring | Rolled ring aluminum forgings | |

| Production Process | Open forging rings are processed by placing a heated aluminum blank on the forging equipment and then hammering or pressing it with a forging hammer or forging press to gradually deform it into a ring shape. | Closed-die forging rings are produced by placing an aluminum blank in a prefabricated mold and then applying pressure to deform it into a ring shape. | Ring-rolled aluminum forgings are processed by continuous rolling and forming through different rollers of a ring rolling mill, and the aluminum billet is gradually pressed into a ring shape. |

| Production equipment | Forging machines such as hammer forging machines, hydraulic forging machines, etc. | Die forging machines such as hydraulic presses, mechanical presses, molds, etc. | ring rolling mill |

| Product advantages | Using simple equipment and processes, the cost is low. | High dimensional and shape accuracy, better surface quality, and high consistency of mass-produced products. | It can roll out ring-shaped products with larger diameter and thinner wall, and the surface finish is the highest after rolling. |

| Applicable items | Produce forged rings with simple shapes and small batches. | Forged rings with complex shapes and high precision requirements | Suitable for producing forged rings with large size and uniform wall thickness. |

- Advanced mold design and manufacturing technology combined with CAD/CAM software-assisted design and processing technology enables high-precision and high-efficiency aluminum alloy forging of closed-die forgings.

- Using advanced intelligent temperature control technology, precise temperature control during the aluminum alloy forging process can be achieved to ensure the plastic deformation performance of the aluminum alloy.

- Advanced heat treatment technology can perform precisely controlled heat treatment on aluminum alloy forged rings to improve their mechanical properties and corrosion resistance.

- CNC forging machine tools use computer control systems to achieve high precision and efficiency in aluminum alloy forging. Its multi-axis control and high automation features meet various complex shapes and high-precision forging needs.

- Equipped with a variety of advanced online quality testing equipment, it can monitor various parameters in the aluminum alloy forging process in real time, and promptly discover and correct production problems.

Chalco large diameter forged ring product property advantages

| Alloy | Temper | Tensile properties of downstream specimens | Brinell hardness | |||

| Tensile strength Rm /MPa | Specifies non-proportional elongation strength | Elongation after break/ % | ||||

| Gauge length 50 mm | A 5 | |||||

| not less than | ||||||

| 6061 | T6 | 260 | 240 | 7 | 6 | 80 |

| 7075 | T6 | 515 | 440 | 7 | 6 | 135 |

| T73 | 455 | 385 | 7 | 6 | 125 | |

| T7352 | 455 | 385 | 7 | 6 | 125 | |

| 2219 | T6 | 400 | 260 | 8 | 7 | 100 |

| 2014 | T4 | 380 | 205 | 11 | 9 | 100 |

| T6 | 450 | 385 | 6 | 5 | 125 | |

| 5083 | O | 270 | 110 | 16 | 14 | - |

| H111 | 290 | 150 | 14 | 12 | - | |

| H112 | 275 | 125 | 16 | 14 | - | |

| 7050 | T74 | 495 | 425 | 7 | 6 | 135 |

- High load capacity and accuracy.

- High density and high hardness.

- Wear-resistant and corrosion-resistant.

- High thermal conductivity

- Good fluidity and plasticity.

- Through forging, aluminum alloy forgings have the same or higher strength-to-weight ratio than steel.

- A variety of surface finishes can be produced for a beautiful appearance.

- Offering high design flexibility, exterior parts typically do not require extensive polishing.

Service industries of Chalco large diameter forged ring

- Aircraft and helicopter wing connecting rings, aircraft engine sealing rings, bearing seats, etc.

- Satellite main frame, spacecraft turbine disk, aerospace thruster pipe, etc.;

- Ship propulsion system, ship transmission system, etc., such as ship bearing rings, thruster rings, etc.

- Oil drilling and extraction equipment, oil refining equipment, etc., such as drill bit supporting rings, pipeline sealing rings, etc.

- Nuclear power plant equipment, nuclear reactor components, etc., such as nuclear power plant sealing rings, reactor support rings, etc.

- Automotive engines, transmission systems, etc., such as piston rings, bearing rings, etc.

- Wheels and transmission systems of high-speed trains, subways and other means of transportation, such as rail vehicle bearing rings, transmission wheel rings, etc.

- Key components of heavy machinery equipment such as excavators, cranes, and road rollers, such as turntable rings, planetary gear rings, etc.

- Key components of thermal power, hydropower, wind power and other energy equipment, such as hydraulic cylinder sealing rings, wind turbine bearing rings, etc.