Streamline tube is a kind of tube with unique appearance, its main features are smooth surface and streamlined shape, commonly oval, flat, etc. This kind of tube is manufactured by extrusion, cold drawing, rolling or welding and other processes, with excellent strength and corrosion resistance, can reduce air or liquid resistance, and improve the stability and aesthetics of the structure.

Chalco aluminum streamline tube introduction

Common streamline tubes, oval and egg-shaped tubes can be made of the following materials: aluminum alloy; 4130 chrome-molybdenum steel; stainless steel; brass; titanium. For specific machinable sizes, please click [Size Table] to view.

Streamlined tubes are widely used in aerospace, automotive, marine and mechanical equipment, especially in applications where drag reduction is a high requirement. Chalco stocks and provides custom streamlined, oval and egg-shaped tubes to meet different project needs.

Chalco aluminum streamline tube product recommendations

Common alloys: 6061 7075 2024 5052 3003

Lightweight, corrosion-resistant, and high-strength. They can be easily shaped to meet various design requirements and have good aesthetics, making them ideal for applications requiring weight reduction and durability. Chalco aluminum alloy tubes are made from different alloys, tailored for specific strength, corrosion resistance, and processing needs.

| Chalco Aluminum Alloy Streamline Tube Hot Sale Size Stock Reference Table | |||||

| Product | Flat inside diameter | Flat length | Major axis | Minor axis | Strut length |

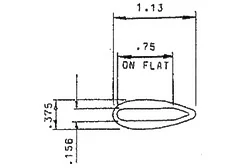

| 6061 T6 Streamline tube | 0.063 | 0.75 | 1.125 | 0.375 | 6 ft |

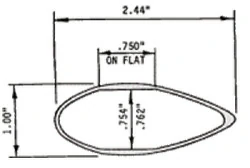

| 6061 T6 Streamline tube | 0.754 to 0.762 | 0.75 | 2.44 | 1 | 10 ft 6 in |

| 6061 T6 Streamline tube | 0.754 to 0.762 | 0.75 | 2.44 | 1 | 95 in |

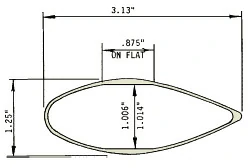

| 6061 T6 Streamline tube | 1.006 to 1.014 | 0.88 | 3.13 | 1.2 | 10 ft 6 in |

| 6061 T6 Streamline tube | 1.006 to 1.014 | 0.88 | 3.13 | 1.2 | 95 in |

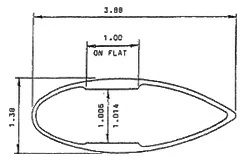

| 6061 T6 Streamline tube | 1.006 to 1.014 | 1 | 3.88 | 1.3 | 11 ft |

| 6061 T6 Streamline tube | 1.006 to 1.014 | 1 | 3.88 | 1.3 | 95 in |

| Can't find the size you need? Click to view the [detailed size chart]or reach out to us directly.Quick Quote | |||||

| Common aluminum streamline tube mechanical properties reference | |||

Small struts Small struts

|

Large struts Large struts

|

Heavy duty struts Heavy duty struts

|

Jury struts Jury struts

|

|

Ultimate = 23, 268 psi Yield=20, 498 psi Sheer = 14, 958 psi Area=.554 sq in Circumference=7.125 Weight = 0.604 #/ft |

Ultimate = 36, 582 psi Yield=32, 227 psi Shear=23, 317 psi Area = .871 sq in Circumference=8.625 Weight = 1.05 #/ft |

Ultimate = 36, 582 psi Yield=32, 227 psi Shear=23, 317 psi Area = .871 sq in Circumference=8.625 Weight=1.05 #/ft |

Ultimate = 7, 938 psi Yield=6, 993 psi Sheer = 5, 103 psi Area = .189 sq in Circumference=2.531 Weight=0.227 #/ft |

Chalco aluminum alloy streamline tube product features

- Lightweight: Aluminum alloy streamlined tubes have low density and light weight, making them suitable for applications that require reducing structural weight, such as aviation and automotive fields.

- High strength: The addition of alloying elements, such as zinc, magnesium, and copper, improves the strength and hardness of aluminum alloys, making them able to withstand greater stress.

- Corrosion resistance: Aluminum alloy streamlined tubes can form a natural oxide film in air and humid environments, effectively preventing corrosion, especially for alloys with strong corrosion resistance such as 5052.

- Machinability: Aluminum alloy can be easily processed into different shapes, including oval, flat, egg-shaped and other streamlined shapes, suitable for various engineering needs.

- Aesthetics: The streamlined design not only enhances the aerodynamic performance, but also improves the appearance of the product and is widely used in decorative structures.

Chalco aluminum streamline tube cooperation areas

- Aerospace: Aluminum alloy streamline tubes are used to manufacture fuselage frames, support structures and wing components. Their lightweight and high-strength properties help improve the efficiency and safety of aircraft.

- Automotive industry: Widely used in automobile frames, chassis, exhaust systems and other components. Especially in new energy vehicles, the lightweight advantage of streamline pipes significantly improves overall performance and energy efficiency.

- Ships and marine engineering: 5052 and 6061 aluminum alloy streamline pipes are suitable for marine equipment and hull structures. Due to their excellent corrosion resistance, they can resist seawater corrosion for a long time and extend their service life.

- Mechanical equipment: used for mechanical supports and moving parts with high strength requirements to reduce fluid resistance and improve operating efficiency.

- Architectural decoration: Aluminum alloy streamlined tubes can also be used in building exterior decoration and internal structure. Because of their beautiful appearance and durability, they are often used in modern architectural design.

Need streamline pipes with other materials?

Although Chalco Aluminum primarily focuses on aluminum products, our group company also operates in other metal sectors, offering a variety of metal products. If you have specific needs for streamlined tubes made from other metal alloys, please feel free to contact our sales representatives. We will make every effort to allocate resources and provide you with the best solutions. Your needs drive our commitment to exceptional service!

4130 chrome molybdenum streamline tube

The 4130 chrome molybdenum streamline tube is a seamless Cr-Mo tube, cold-drawn to minimize wind resistance, achieving 10 times less drag than round tubes.

Specification:ASTM A519; SAE 4130; AMS 6360; AMS 6371; MIL-T-6736

Contact us now

| STANDARD 4130 ALLOY STREAMLINE SHAPES | |||

| Major Axis | Minor Axis | Wall | Equivalent Round |

| 1.012 | 0.428 | 0.035 | 0.75 |

| 1.18 | 0.5 | 0.035 | 0.875 |

| 1.18 | 0.5 | 0.049 | 0.875 |

| 1.313 | 0.688 | 0.049 | 0.974 |

| 1.349 | 0.571 | 0.035 | 1 |

| 1.349 | 0.571 | 0.049 | 1 |

| 1.57 | 0.58 | 0.049 | 1.12 |

| 1.675 | 0.87 | 0.049 | 1.325 |

| 1.685 | 0.714 | 0.049 | 1.25 |

| 1.685 | 0.714 | 0.065 | 1.25 |

| 1.786 | 1.064 | 0.035 | 1.324 |

| 1.786 | 1.064 | 0.049 | 1.324 |

| 2.023 | 0.857 | 0.049 | 1.5 |

| 2.023 | 0.857 | 0.065 | 1.5 |

| 2.36 | 1 | 0.049 | 1.75 |

| 2.36 | 1 | 0.058 | 1.75 |

| 2.67 | 1.44 | 0.049 | 1.98 |

| 2.697 | 1.143 | 0.049 | 2 |

| 2.697 | 1.143 | 0.065 | 2 |

| 3.372 | 1.429 | 0.049 | 2.5 |

| 3.372 | 1.429 | 0.065 | 2.5 |

| Mechanical properties (Conforms with MIL-T-6736B Condition N or AMS 6360) | |||

| Wall Thickness (in) | Min. Yield Strength (psi) | Min. Tensile Strength (psi) | Min. Percent Elongation in 2” |

| Up To 0.187 | 95, 000 | 105, 000 | 15% |

Application fields of 4130 chrome molybdenum streamline tube:

- Aerospace: Used to manufacture lightweight and high-strength structural parts, such as fuselage frames and support frames, to reduce air resistance and improve flight performance.

- Racing chassis: The frame and chassis commonly used in racing cars because of its high strength and light weight, which helps to improve the speed and handling of the vehicle.

- Mechanical structural parts: In engineering projects that require durability and lightness, such as the frames of high-performance bicycles and motorcycles.

Stainless steel streamline pipe

Stainless steel streamlined tubes are usually made of 304 or 316 stainless steel, which have excellent corrosion resistance and strength and are suitable for harsh environments. Its streamlined design reduces resistance and increases the service life and performance of the product.

Contact us now

- Ship Engineering: Due to its corrosion resistance, it is widely used in ship hulls, ship structures and marine equipment, resisting seawater corrosion and ensuring long-term use.

- Building structures: Used for building structures with high strength and aesthetic requirements, especially exposed metal frames and decorative architectural elements.

- Food Processing Equipment: Commonly used in pipes and equipment in food and beverage processing systems due to its antibacterial and corrosion-resistant properties.

Brass flow line tube

The brass flow tube is made of an alloy of copper and zinc, with good corrosion resistance, conductivity and machinability, and a high surface finish. Its streamlined design helps to improve the appearance and reduce fluid resistance.

Contact us now

The brass flow tube is made of an alloy of copper and zinc, with good corrosion resistance, conductivity and machinability, and a high surface finish. Its streamlined design helps to improve the appearance and reduce fluid resistance.

- Heat exchange equipment: In HVAC equipment, air conditioners and radiators, it plays a role due to its excellent thermal conductivity and corrosion resistance.

- Decorative buildings: Commonly used for indoor and outdoor decoration, the luster and corrosion resistance of brass enhance the aesthetics and is suitable for stair railings, door handles, etc.

- Musical instrument manufacturing: Widely used in brass instruments such as trumpet, saxophone, etc. due to its good sound conductivity and beautiful appearance.

- Other: Great for making temporary models and skeletons. Most commonly used for reinforcing aluminum skeletons (for bone structure), hip/chest fabrication, rigging, and hand/wrist replacements. Also great for prop makers and modelers, crafts, machine shops, and architectural applications.

Titanium alloy streamline tube

Titanium alloy streamlined tubes are lightweight, high-strength, and extremely corrosion-resistant and heat-resistant, and are widely used in structural parts in extreme environments. Their streamlined design improves aerodynamic performance and is suitable for high-end technology fields.

Contact us now

- Aerospace: Lightweight, high-strength components for aircraft and spacecraft, ideal for high-temperature and corrosive environments.

- Medical devices: Due to its biocompatibility, titanium alloy flow tubes are often used to manufacture medical devices and implants, such as surgical instruments and orthopedic stents.

- Chemical Equipment: In chemical and petroleum equipment, it is used for pipes and equipment with high corrosion resistance requirements to ensure the stability of materials in extreme environments.

- High-performance automobiles: Used in exhaust systems and chassis of racing cars and high-end cars, improving overall performance due to its lightweight and high temperature resistance.

Chalco streamlined aluminum tube production and processing

While traditional streamlined tubing is produced through a cold-drawn process in random lengths (typically 10 to 17 feet), Chalco’s high-performance tubing is roll-formed, where round tubing is passed through a series of progressive rollers and dies. This process results in a more consistent and repeatable shape.

Although cold drawing is an effective way to produce streamlined tubes, roll-formed tubes have tighter tolerances, avoid the bending problems common in cold-drawn tubes, and produce a straighter product. In addition, roll-forming allows the wall thickness of the parent round tube to be maintained, providing more wall thickness options.

Extruded flowline tube

Heating the material at high temperature and extruding it into a tube has the advantage of manufacturing seamless streamlined tubes, ensuring uniform structure, high strength and good compression resistance of the tube, which is suitable for high-strength applications.

Cold drawn streamline tube

By stretching the tube at room temperature, the tube dimensions are further precisely controlled in the mold, further improving its mechanical properties. With higher dimensional accuracy and surface finish, it is suitable for applications requiring tight tolerances.

Roller-formed streamlined tube

The tube material is processed into a streamlined shape through a rolling process. It can maintain the consistency of tube wall thickness, is suitable for medium and large-sized streamlined tubes, and has high production efficiency.

Welding flow line tube

Welding technology can connect plates or pipes into customized streamlined structures, which are suitable for large diameters or special shapes, have low production costs, and can flexibly meet non-standard specification requirements.

Why choose Chalco as your supplier for your streamline tube project?

Wide range of products

Chalco provides a variety of streamlined pipes, including aluminum alloy, titanium alloy, stainless steel, brass and other materials to meet the needs of different projects. Whether it is used in aerospace, automobile manufacturing, or architectural decoration, Chalco can provide suitable solutions.

Full range of sizes in stock

In order to cope with urgent projects and fast delivery needs, Chalco has a full range of stock sizes. Flowline pipes of different specifications and shapes are ready for shipment at any time, ensuring that projects can proceed on time without having to wait for production for a long time.

Improved production and processing capabilities

Chalco has advanced production equipment and technology, capable of performing a variety of processing techniques such as extrusion, cold drawing, welding and rolling. The company uses high-end equipment such as 500MN extruders to ensure production efficiency and quality, and can meet customized needs of different shapes and complexities.

Strict product quality inspection

Chalco implements strict quality control measures to ensure that every flow line tube has passed rigorous testing before leaving the factory. Whether it is dimensional accuracy, surface finish, or internal quality, Chalco strictly follows international standards to provide customers with reliable high-quality products.

Chalco streamline tube related other aluminum tube products

Chalco can provide additional processing services for aluminum streamline

- Surface treatment: Depending on the project requirements, the flow tube can be anodized, electroplated, sprayed or polished to improve corrosion resistance and aesthetics.

- Cutting and Forming : We can cut to custom lengths and bend, curl or otherwise shape as required to accommodate complex designs.

- Welding and assembly: Welding services can be provided to combine flow tubes with other structural parts or components to provide a complete solution for complex structures.

- Heat Treatment: For projects requiring higher strength or special properties, heat treatment services such as quenching and aging can be provided for flow line pipes.

Streamline tube selection guide

- Material selection: Choose the right material according to project needs, aluminum alloy is suitable for lightweight and corrosion-resistant requirements, 4130 chromium- molybdenum steel is suitable for high strength, titanium alloy is suitable for extreme environments, stainless steel and brass are suitable for corrosion resistance and decorative applications.

- Size and shape: Determine the size and shape of the streamline tube (oval, flat, egg-shaped, etc.) according to the application scenario. Different streamline designs can significantly reduce air resistance.

- Processing needs: Consider whether additional processing, such as cutting, welding, bending, etc., is required to ensure that the flow line tube meets the specific needs of the project.

- Surface treatment: If the project is in a corrosive environment or has high requirements on appearance, choose surface treatments such as anodizing, electroplating or spraying.

- Application environment: Determine the temperature, pressure, corrosiveness and other factors of the use environment to select the most suitable streamlined tube material and specifications.

Chalco streamline tube detailed size table

| Tube Diameter | Imperial (Inches) | Metric ( Millimetres ) |

| 0.375″ | 0.45 x 0.24 | 11.5 x 6.3 |

| 0.500″ | 0.60 x 0.33 | 15.3 x 8.53 |

| 0.500″ | 0.62 x 0.25 | 16.0 x 6.6 |

| 0.625″ | 0.81 x 0.34 | 20.7 x 8.7 |

| 0.625″ | 0.85 x 0.27 | 21.6 x 7.0 |

| 0.750″ | 0.95 x 0.48 | 24.1 x 12.2 |

| 0.750″ | 0.98x0.36 | 25.1 x 9.20 |

| 0.875″ | 1.14 x 0.46 | 29.1 x 11.9 |

| 1.000″ | 1.33 x 0.55 | 33.8 x 14.0 |

| 1.000″ | 1.35 x 0.51 | 34.5 x 13.0 |

| 1.000″ | 1.35 x 0.57 | 34.4 x 14.6 |

| 1.125″ | 1.41 x 0.75 | 36.0 x 19.3 |

| 1.125″ | 1.44 x 0.77 | 36.5 x 19.6 |

| 1.125″ | 1.46 x 0.70 | 37.2 x 17.8 |

| 1.125″ | 1.46 x 0.71 | 37.2 x 18.1 |

| 1.125″ | 1.48 x 0.70 | 37.7 x 17.9 |

| 1.125″ | 1.48 x 0.71 | 37.6 x 17.9 |

| 1.125″ | 1.51 x 0.57 | 38.4 x 14.5 |

| 1.125″ | 1.52 x 0.54 | 38.7 x 13.8 |

| 1.125″ | 1.59 x 0.44 | 40.6 x 11.3 |

| 1.250″ | 1.64 x 0.74 | 41.7 x 19.0 |

| 1.250″ | 1.67 x 0.72 | 42.5 x 18.5 |

| 1.250″ | 1.69 x 0.71 | 43.1 x 18.1 |

| 1.250″ | 1.72 x 0.63 | 43.9 x 16.2 |

| 1.250″ | 1.73 x 0.53 | 44.0 x 13.7 |

| 1.250″ | 1.73 x 0.57 | 44.0 x 14.5 |

| 1.250″ | 1.74 x 0.54 | 44.1 x 13.7 |

| 1.250″ | 1.76 x 0.46 | 44.8 x 11.8 |

| 1.250″ | 1.81 x 0.51 | 46.0 x 13.0 |

| 1.375″ | 1.83 x 0.78 | 46.5 x 20.0 |

| 1.500″ | 1.90 x 0.96 | 48.4 x 24.5 |

| 1.500″ | 1.92 x 0.96 | 49.0 x 24.5 |

| 1.500″ | 1.94 x 0.89 | 49.3 x 22.7 |

| 1.500″ | 1.96 x 0.89 | 49.8 x 22.7 |

| 1.500″ | 2.00 x 0.96 | 50.0 x 24.5 |

| 1.500″ | 2.02 x 0.72 | 51.7 x 18.4 |

| 1.500″ | 2.02 x 0.84 | 51.4 x 21.5 |

| 1.500″ | 2.06 x 0.61 | 52.5 x 15.7 |

| 1.500″ | 2.09 x 0.65 | 53.2 x 16.6 |

| 1.500″ | 2.10 x 0.57 | 53.3 x 14.5 |

| 1.500″ | 2.12 x 0.70 | 54.0 x 18.0 |

| 1.625″ | 2.11 x 0.97 | 53.8 x 24.8 |

| 1.625″ | 2.15 x 0.87 | 54.7 x 22.0 |

| 1.750″ | 2.20 x 1.22 | 56.0 x 31.0 |

| 1.750″ | 2.28 x 0.63 | 58.0 x 16.0 |

| 1.750″ | 2.28 x 0.99 | 58.0 x 25.3 |

| 1.750″ | 2.52 x 0.72 | 64.0 x 18.2 |

| 1.875″ | 2.51 x 0.95 | 64.0 x 24.2 |

| 2.250″ | 2.81 x 1.58 | 71.5 x 40.3 |