Chalco can supply anodized orange peel embossed aluminum sheets, which are mainly used in cold storage, freezers, color-coated embossed stucco aluminium coil for home appliance panel decoration, embossed corrugated sheets for roofs, anti-corrosion coated embossed aluminum sheets for air-conditioning pipes, and patterns coils are used in machinery platforms, automotive road skid coil industries, etc.Quick Quote

Stucco embossed aluminum coil pattern

Stucco embossed aluminum coil

The surface presents an embossed aluminum coil similar to orange peel.

Mainly used in freezer, cold storage, refrigerator lining board, orange peel embossed aluminum coil for decoration of cabinet partition and embossed aluminum foil coil for floor heating heat conduction, etc.

Rhombus/diamond embossed aluminum coil

The surface presents a beautiful rhombus pattern metal aluminum coil.

It is suitable for luggage, packaging, decorative lights. Chalco is a diamond embossed aluminum coil supplier, and can provide diamond embossed aluminum coils of various materials.Quick Quote

Hemisphere embossing aluminum coil

The surface presents a spherical embossed aluminum coil. Commonly there are hemispherical pattern aluminum coil and double-sided spherical embossed aluminum coil.

The concave and convex spherical pattern can increase the surface area of the aluminum coil and play a good heat dissipation effect. It is mainly used for automobile chassis heat dissipation, engine shield, exhaust pipe heat shield, etc.

Cobblestone (hammer/bean) embossed aluminum roll

This kind of aluminum roll is usually made of mirror aluminum oxide base material, the surface is densely covered with embossing the size of bean grains, with strong astigmatism effect, and the reflectivity is as high as 85%.

It is widely used in lighting and decoration industries. Mirror embossed aluminum coils are often used in lamp lighting and reflector lampshades.Quick Quote

Corrugated embossed aluminum sheet

The surface of the corrugated aluminum sheet is corrugated, light in weight and corrosion-resistant, and is often used in the roof panels of civil buildings, warehouses and houses.

Aluminum tiles are often used in thermal insulation projects in power plants and chemical plants.

Power plants are mostly made of 1060 material. Because of their corrosive environment, chemical plants choose 3003 aluminum-manganese anti-rust alloy material. The amplitude becomes larger, which is more conducive to drainage and building wall panels.

Chalco can produce and process products from 0.2mm-2.0mm. Users can customize according to their own requirements, and other special tile types. Our company can order different tile machine molds for production according to the quantity.Quick Quote

Aluminum tread coil

Common model: 5052 H114 five-rib gold pattern coil; 3003 H22 compass aluminum alloy pattern coil; 1060 lentil-shaped pattern aluminum coil.

The aluminum alloy pattern coil processed from 1060 base can adapt to the ordinary environment and has a low price. Usually cold storage, floors, and outer packaging use this patterned aluminum sheet.

3003 H22 diamond coil, called anti-rust aluminum coil, has a slightly higher strength than ordinary aluminum alloy pattern coil, and has certain anti-rust performance. But the hardness and corrosion resistance cannot reach the pattern coil of 5000 series. So, this product is used in applications that do not require Strict rust prevention, such as truck models, cold storage floors.

5052 checker coil has good corrosion resistance, hardness and rust resistance. It is usually used in special places, such as ships, carriage lights, and humid environments. This kind of aluminum coil has high hardness, certain load-bearing capacity and anti-skid effect.

6061 6082 checker coils will be used when a higher strength is required.Quick Quote

Stucco embossed aluminum coil specifications

| Alloy | 1060 1100 3003 5052 8011 |

| Temper | O, H14, H24, H26, H32 |

| Sleeve ID | 505mm |

| Embossed aluminum coil thickness | 0.06mm-3.0mm |

| Embossed aluminum coil width | 10mm-1200mm |

| Embossed aluminum coil length | sheet or coil (special size can be customized) |

| Production standard | (GB/T 3618-2006), ASTM B209 |

Stucco embossed aluminum coil surface finish

Anodized stucco embossed aluminum coil

Anodized surface-treated orange peel embossed aluminum sheet with a thin layer of aluminum oxide formed on the surface.

| Alloy | 1070, 1060, 3003 anodized embossed aluminum coils |

| Thickness | 0.3-2.0mm |

| Temper | mainly H14/H24/H18 |

| Characteristics | waterproof, abrasion resistance, wear resistance, antifouling, corrosion resistance and other characteristics. |

| Application | it is used to decorate the interior of refrigerators and the exterior of cooling systems. |

Color-coated embossed aluminum coil

The color-coated embossed aluminum coil is also called embossed color coated coil. Its surface is coated with one or several layers of polyester, fluorocarbon and varnish through the roller coater.

| Alloy | commonly used alloys are 1060 3003 5052 color-coated embossed aluminum coil |

| Thickness | 0.3-2.0mm |

| Temper | H24/H32 |

| Embossed Pattern | color-coated orange peel pattern, color-coated diamond pattern, etc. The colors are bright with exquisite embossing patterns, making the embossing color-coated. |

| Application | the board is more decorative and is often used in decoration, cabinets, and home appliance panels. |

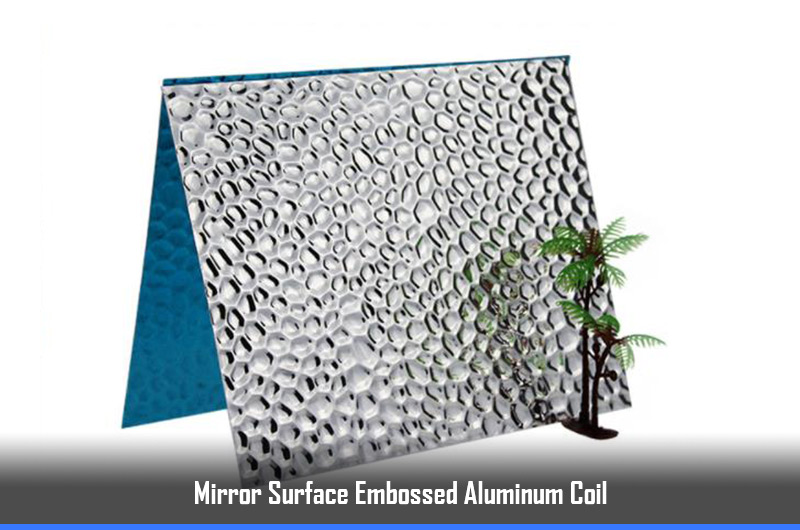

Mirror surface embossed aluminum coil

Using high-quality mirror aluminum coils, the mirror aluminum coil products with concave and convex patterns are processed by pressure on the embossing equipment.Quick Quote

They are usually used as reflective materials for lighting fixtures, which can enhance the light efficiency by more than 60% and save energy.

1070 mirror hammer embossed aluminum coil, when used as interior decoration, the mirror reflection effect can make the space expand and present an illusory effect, and the rolling surface of its reflection effect enhances the architectural performance of the house.

It can also be used in solar heat collecting and reflective materials, building curtain walls, household appliance panels, electronic product shells, furniture kitchens, interior and exterior decoration of automobiles, signs, signs, luggage, jewelry boxes and other fields.

Kraft paper clad stucco embossed aluminum coil

The aluminum coil is hot-compressed with kraft paper, and then de-embossed. After embossing, its strength and anti-corrosion performance are further enhanced.

It is mainly used for anti-corrosion and thermal insulation projects, and is exported to foreign customers, especially the pipeline thermal insulation projects of Middle East Petroleum.

Chalco exports 1, 000 tons/year of 3003 H24 composite kraft paper embossed aluminum coil, which is well received by domestic and foreign users.

The anti-corrosion performance of the aluminum coil itself is relatively superior, and the service life of the aluminum coil is greatly enhanced after being compounded with a layer of kraft paper.

It also has a certain adsorption effect on the moisture inside the pipeline.

Blue polymer coating embossed aluminum coil

Aluminium roll sarin film (blue sarin film) is a multi-layer composite film of polyethylene and sarin polymer with a total thickness of 76 microns.

| Alloy | commonly used alloys are 1060 3003 blue sarin film composite embossed aluminum coil. |

| Thickness | 0.3-2.0mm |

| Temper | H24/H14 |

Sarin film is firmly coated on the metal surface under high temperature and high pressure, after embossing. It can effectively help Anti-corrosion of metal protective layer of pipeline insulation materials in oil refineries (power plants, chemical plants).

Anti-Corrosion coated embossed aluminum coil

| Alloy | the anti-corrosion coating aluminum foil used on the upper and lower surfaces of the phenolic composite air duct is usually 8011 aluminum foil, 1100 aluminum foil. |

| Thickness | 0.018-0.2mm |

| Temper | the temper is mainly H22/H18. |

Aluminum foil needs to be embossed or coated first, then compounded with phenolic board or polyurethane board.

Why choose Chalco stucco embossed aluminum coil?

- Embossed aluminum coils can be customized: checkered pattern embossed aluminum coil, leather pattern embossed aluminum coil, wavy pattern material, water corrugated aluminum pattern coil, rattan pattern aluminum coil, three-dimensional triangular aluminum pattern coil, strip pattern aluminum coil, pebble aluminum pattern coil, patterned aluminum coil Aluminum pattern coil, triangular strip pattern aluminum coil, butterfly pattern aluminum coil, etc.

- The anodized embossed aluminum coil is of good quality

- Coil surface is free of rainbows, white spots, oil stains, etc.

- Color coated embossed aluminum coil has many colors can supply

- Reliable supplier of embossed aluminum coils: Chalco has a strict quality control to the product. Chalco has a special quality inspection team, taking pictures of customers before each shipment, and making inspection reports.

- Good delivery time: the production delivery time is short. Chalco has 2000 tons of inventory and can be shipped immediately.

- Good packaging for stucco embossed aluminum coil: vertical fumigation-free packaging or horizontal packaging, suitable for long-distance shipping.

Manufacturing process of stucco embossed aluminum coil

The embossed aluminum coil is a flat aluminum coil that is calendered by an embossing roller to form various concave and convex patterns on the surface. The surface is anodized, color-coated, film-coated or laminated with kraft paper, etc.

- Melting and holding furnace

- Cold rolling

- Stretching and straightening

- Acid and alkali washing, then drying

- Embossing production

- Anodising

- Cutting and packing