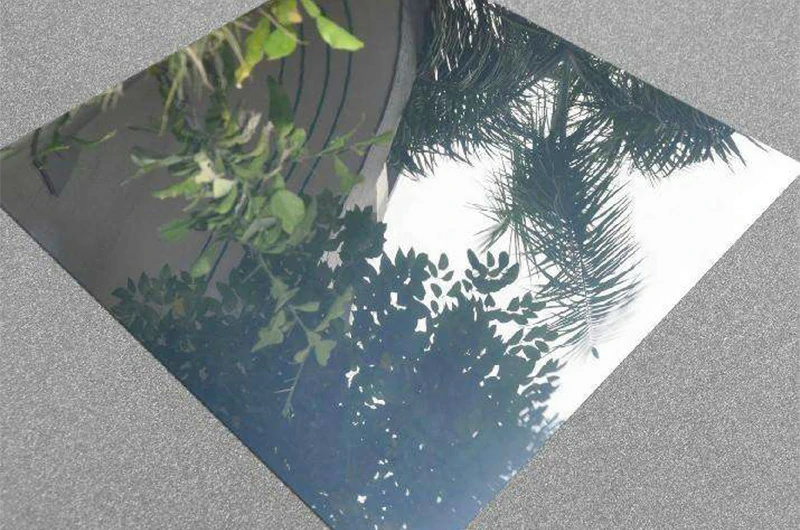

Mirror Aluminum Sheet is an aluminum sheet that has undergone rolling, embossing, grinding, and polishing treatments to achieve a mirror-like surface effect. It possesses excellent corrosion resistance and high reflectivity. This product is widely used in various fields such as reflective lighting, indoor and outdoor architectural decoration, automotive interior and exterior decoration, high-end cosmetic packaging, and luxury liquor labels, among others.

- The reflectivity of regular mirror aluminum: 86%

- The reflectivity of ultra-high reflectivity mirror aluminum: 95%

Our mirror aluminum sheet can be as thin as 0.08mm, making it a truly ultra-thin material. The ultra-thin design not only helps save material costs but also meets the demand for lightweight and flexibility, making it suitable for various application scenarios.

Click to View the Ultra-Thin Mirror Aluminum Product Guide

Ultra-thin mirror aluminum sheet introduction

Product: Ultra-Thin Mirror Aluminum Sheet

Reflectivity: 80%, 86%, 95%

Glossiness: 780GS - 820GS

Material: 1050, 1060, 1070, 1085, 3003, 3105, 5052, 5005, 5052

Thickness: 0.08mm - 6.0mm

Width: 50mm - 1500mm

Length: 1000mm - 6000mm

Hot-Selling Sizes: 48"x 96", 48"x 120"

Surface: Coated, Embossed, Brushed, Anodized, etc.

Applications: Construction industry, shipbuilding industry, decoration, industrial, manufacturing, mechanical hardware, etc.

Standards: EN 485, ASTM B209, EN573

Why choose ultra-thin mirror aluminum sheet?

Ultra-Thin Design: The ultra-thin mirror aluminum sheet we offer can be as thin as 0.08mm, significantly reducing weight and providing greater design flexibility.

High-Quality Materials: Made from high-quality aluminum alloys to ensure strength and durability, suitable for various applications.

Excellent Reflectivity: The mirror finish offers outstanding reflectivity, effectively bouncing light and enhancing both the aesthetic appeal and functionality of the product.

Cost-Effectiveness: The ultra-thin design not only reduces weight but also significantly saves on material costs, improving the overall economics of the project.

Hot-selling products of ultra-thin mirror aluminum sheet

1050/1060/1070 Thin Mirror Alu Coil

Mirror aluminum, made from pure aluminum alloy (99.5%+), offers up to 86% reflectivity and is widely used in lighting and architecture.

Features:Color-coated, Embossed mirror aluminum

Advantages:Simple processing, low cost

1085 Ultra-Thin Mirror Aluminum Coil

1085, once imported, is now locally made at 30% less cost. With 86% reflectivity, it's used in VR devices, medical tools, and frosted text effects.

Type:Anodized mirror aluminum

Advantages:Fingerprint-resistant, more durable

3003/3105 Ultra-Thin Mirror Alu Coil

An Al-Mn alloy, 10% stronger than the 1000 series, offers great bending, deep-drawing, 94% reflectivity, and is used in automotive interiors and architecture.

Type:Color-coated, Embossed, Anodized

Advantages:Higher strength, more durable

5052/5083 Mirror Aluminum Coil

An Al-Mg alloy, known for strength, corrosion resistance, and 95% reflectivity, is used in facades, electronic casings, and solar equipment.

Type:Color-coated , Embossed , Anodized

Advantages:More robust, better corrosion resistance

5182 Mirror Aluminum Coil

5182, a high-strength, ductile material, is widely used for tank vehicles. In the Middle East, its mirror aluminum surface reflects sunlight, lowering tank temperature and enhancing safety.

Advantages:High strength, good ductility

8014 High Formability Mirror Alu Coil

The 8014 high-end mirror aluminum sheet is widely used in stealth fighter skins, solar heat collector panels, high-end cosmetic packaging, and luxury car badges, among other premium applications.

Product categories of ultra-thin mirror aluminum sheet

Ultra-Thin Color-Coated Mirror Aluminum Sheet

Ultra-thin color-coated mirror aluminum sheet is a type of mirror aluminum that undergoes a special coating treatment, combining excellent reflectivity with a wide range of color options. Its ultra-thin characteristics typically range from 0.08mm to 0.5mm, making it highly efficient in terms of lightweight and cost control. It not only has good corrosion resistance and oxidation resistance, but also exhibits unique aesthetic effects in various applications. It is widely used in home appliance panels, architectural decoration, and more.

Most Popular Ultra-Thin Color-Coated Mirror Aluminum

Champagne Ultra-Thin Mirror Aluminum Sheet

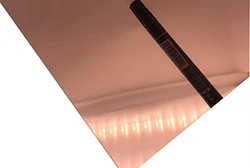

Red Copper Ultra-Thin Mirror Aluminum Sheet

Rose Gold Ultra-Thin Mirror Aluminum Sheet

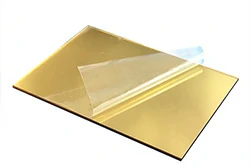

Gold Ultra-Thin Mirror Aluminum Sheet

Red Ultra-Thin Mirror Aluminum Sheet

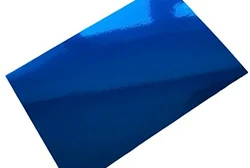

Blue Ultra-Thin Mirror Aluminum Sheet

Ultra-Thin mirror anodized aluminum sheet

Anodized mirror aluminum sheet is processed by placing the mirror sheet in an electrolyte solution for oxidation, forming a thin oxide layer on the surface. After oxidation, the mirror sheet's performance is enhanced and it becomes more resistant to damage. The anodization process can also include a coloring treatment, allowing it to be dyed in various colors. It is widely used in electronic device casings, high-end home appliances, and other applications.

Ultra-thin embossed mirror aluminum sheet

Ultra-thin embossed mirror aluminum sheet is produced using a special roller embossing process, combining a mirror finish with unique concave-convex textures. Not only does it offer high reflectivity, but it also provides excellent decorative effects, making it widely used in home decor, diffuse lighting fixtures, automotive interiors, and more. It significantly enhances the visual appeal and texture of products.

Embossed Mirror Aluminum Types Available from Chalco Henan

Ultra-Thin cobble embossed aluminum mirror sheet

Ultra-Thin orange peel embossed aluminum mirror sheet

Ultra-Thin Diamond aluminum mirror sheet

Ultra-Thin ACP mirror sheet

The ultra-thin ACP mirror sheet consists of a three-layer structure, with the top and bottom layers being mirror aluminum. While the outer layer of standard mirror aluminum composite panels is typically 0.3mm, we can achieve a minimum thickness of 0.08mm. The ultra-thin design not only reduces weight but also significantly cuts costs. This composite sheet is widely used in building facades, advertising signage, and indoor decorations, providing an elegant appearance while offering excellent weather resistance and low maintenance.

Features of ultra-thin mirror aluminum sheet

Lightweight: The thickness can be as thin as 0.08mm, reducing overall weight, which facilitates transportation and installation.

High Reflectivity: The smooth surface offers excellent reflectivity, with a maximum reflectivity of up to 95%, making it ideal for decorative and lighting applications.

Corrosion Resistance: Anodized treatment enhances corrosion resistance, extending the product's lifespan.

Good Workability: Easy to cut, bend, and shape, adapting to a variety of manufacturing needs.

Cost-Effective: The ultra-thin design effectively saves materials and reduces production costs.

Aesthetic Appeal: It offers excellent visual effects, making it suitable for high-end decoration and design applications.

Applications of ultra-thin mirror aluminum sheet

Architectural Decoration: Ultra-thin mirror aluminum sheets are widely used in building facades, adding a modern touch and visual appeal to buildings. Its high reflectivity enhances light utilization, creating a bright and airy visual effect. The lightweight nature also reduces the overall building weight, making installation and maintenance easier.

Automotive Industry: In the automotive industry, ultra-thin mirror aluminum is used in parts like front lights, interior trims, and badges. Its lightweight design helps improve energy efficiency and performance, while also enhancing the stylish appearance of vehicles.

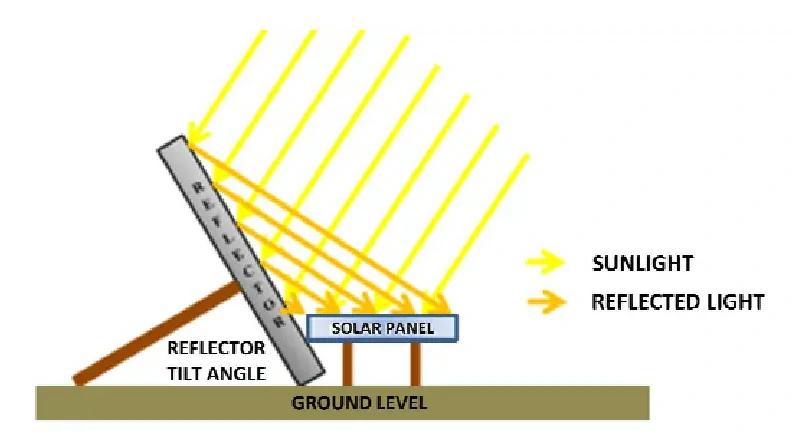

Solar Devices: Ultra-thin mirror aluminum is used in solar heat collector panels, utilizing its high reflectivity to improve solar energy absorption efficiency, promoting the use of renewable energy. Its weather resistance and corrosion resistance also ensure the long-term stability of the equipment.

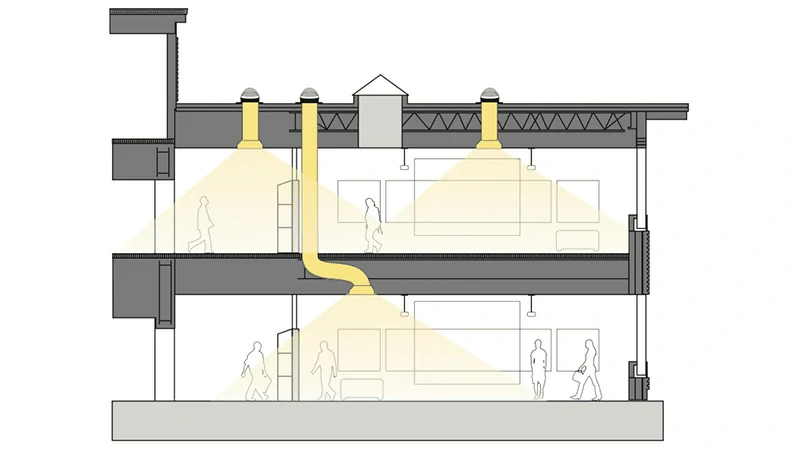

Tubular Daylight Lighting Systems: Ultra-thin mirror aluminum can effectively reflect and diffuse natural light in tubular daylight lighting systems, improving indoor lighting effects. This application is both energy-saving and enhances the comfort of indoor environments.

Lighting Fixtures: Ultra-thin mirror aluminum is used as a reflector in lighting fixtures to enhance light reflection and distribution, improving lighting efficiency. Its lightweight design is suitable for various lighting fixtures, ensuring stable installation and reducing energy consumption.

Commercial Applications: In the advertising signage industry, ultra-thin mirror aluminum is used to create billboards, signs, and product displays, enhancing visibility and attractiveness. Its elegant surface not only catches the eye of passersby but also maintains excellent visual effects in varying lighting conditions.

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

Ultra-thin mirror aluminum sheet product guide

Optical Performance of Ultra-Thin Mirror Aluminum Sheets

| Total reflectivity (Y/D65/2°) | 95%±2% |

| Diffuse reflectivity (Y/D65/2°) | <1% |

| Specular reflectivity (60° longitudinal) | ≥91% |

| Specular reflectivity (60° horizontal) | ≥91% |

| Rainbow | No obvious rainbow appearance |

Durability testing of ultra-thin mirror aluminum sheets

| Neutral salt spray test (coated sample / 72 hours / ΔY% < 1.5%) | ΔY% < 1.5% |

| Cross scratch adhesion test (no obvious film removal) | Unclear membrane removal |

| High temperature baking test (180°C / 2 hours / ΔY% < 1.0%) | ΔY% < 0.5% |

| Artificial climate chamber test (40°C - 95% r.H. / 168 hours / ΔY% < 1.0%) | ΔY%≤1.0% |

| Artificial climate chamber test (85°C - 85% r.H. / 24 hours / ΔY% < 1.0%) | ΔY%≤1.0% |

| Ultraviolet resistance test (UV light continuous irradiation for 2 weeks / ΔY% < 1.0%) | ΔY%≤1.0% |

Forming tolerances of ultra-thin mirror aluminum sheets

| Thickness tolerance of coils and sheets [mm] | 8% of thickness |

| Width tolerance of coils [mm] | +2.00/-0.00 |

| Width tolerance of split coils [mm] | +0.06/-0.00 |

| Longitudinal curvature of coils [mm] | Longitudinal bending ≤ 1 per 1000mm length |

| Sheet dimensions [mm] | < 1250 (width) < 4000 (length) |

| Sheet dimensions tolerance [mm] | +0.50/-0.00 (< 500mm) +1.50/-0.00 (500 - 2000mm) +2.50/-0.00 (2000 - 4000mm) |

What is the working principle of mirror aluminum sheets?

The working principle of mirror aluminum sheets is based on the reflective properties of light. When light strikes the surface of the aluminum sheet, the smooth surface reflects the light back in the same direction through a thin reflective layer. This high reflectivity makes mirror aluminum sheets highly effective in various applications such as solar panels, automotive headlights, and lighting equipment.

What are the processing methods for mirror aluminum sheets?

- Rolling and Polishing: Through rolling and polishing, the surface of the aluminum sheet becomes smooth and reflective. This is the most common method for manufacturing mirror aluminum sheets, effectively removing surface defects and improving gloss.

- Spray Coating: Spray coating is a crucial surface treatment for aluminum sheets. The correct spray coating and drying process must be applied according to the specific requirements of the mirror aluminum sheet. Only evenly coated aluminum sheets can be used for high-quality mirror aluminum products.

- Electropolishing: Electropolishing involves applying an electrical current to dissolve the metal surface's oxide layer, achieving a smooth finish. The metal's anode dissolves in the electrolyte, creating a polished surface.

- Chemical Polishing: This method uses chemical reactions to remove surface defects and the oxide layer, achieving a mirror-like finish. It is usually done by immersing the aluminum in specific chemical solutions.

What is the difference between mirror aluminum and ultra-reflective mirror aluminum?

Surface Treatment

- Mirror Aluminum Sheet: Typically polished, with a smooth surface and relatively high reflectivity, but not necessarily reaching ultra-high reflective standards.

- Ultra-Reflective Mirror Aluminum: Undergoes more complex processing and coating treatments. The surface precision is much higher, allowing for superior light reflection.

Reflectivity

- Mirror Aluminum Sheet: Reflectivity typically ranges from 70% to 85%, suitable for applications that require moderate reflection, such as architectural decoration, signage, etc.

- Ultra-Reflective Mirror Aluminum: Reflectivity typically exceeds 90%, and can reach up to 95%, making it ideal for applications where high light reflection is crucial, such as solar heat collectors and high-end lighting equipment.

Application Scenarios

- Mirror Aluminum Sheet: Widely used in architectural decoration, home decor, and advertising signage, focusing on aesthetics and basic reflection.

- Ultra-Reflective Mirror Aluminum: Mostly used in high-tech fields such as optical devices, aerospace, and high-efficiency solar systems, emphasizing performance and efficiency.

Why can ultra-thin mirror aluminum sheets significantly reduce costs?

Let's consider a large commercial building project requiring 3, 000 square meters of mirror aluminum sheets for facade decoration. Assume the cost of regular mirror aluminum sheets is $6.43 per kg, and the cost of ultra-thin mirror aluminum sheets is $9.29 per kg. We will analyze the weight and cost differences between using regular mirror aluminum sheets with a thickness of 0.5mm and our ultra-thin mirror aluminum sheets with a thickness of 0.08mm.

Regular mirror aluminum (0.5mm thickness):

Weight per square meter = 0.5mm × 2.7g/cm³ = 1.35kg/m²

Total weight = 3, 000m² × 1.35kg/m² = 4, 050kg

Ultra-thin mirror aluminum (0.08mm thickness):

Weight per square meter = 0.08mm × 2.7g/cm³ = 0.216kg/m²

Total weight = 3, 000m² × 0.216kg/m² = 648kg

2. Cost Calculation

Cost of regular mirror aluminum = 4, 050kg × $6.43/kg ≈ $26, 000

Cost of ultra-thin mirror aluminum = 648kg × $9.29/kg ≈ $6, 036.72

3. Cost Savings

You could save:

$26, 000 − $6, 036.72 ≈ $19, 963.28

By using ultra-thin mirror aluminum sheets, you can save up to 76% of the cost, making it an excellent choice for reducing costs and improving efficiency. Feel free to contact us for ordering!Quick Quote

Does the reflectivity of mirror aluminum sheets change over time?

Yes, the reflectivity of mirror aluminum sheets can change over time due to the following reasons:

- Oxidation: Aluminum surfaces are prone to oxidation in the air, forming an oxide layer that affects reflectivity.

- Pollution: Dust, dirt, and other pollutants can accumulate on the surface of aluminum sheets, reducing their reflectivity.

- Wear and Tear: During use, the surface may wear down, causing a decline in reflectivity.

Solution:

To maintain the reflectivity of mirror aluminum sheets, regular cleaning and maintenance are recommended. Using specialized aluminum protectants can effectively slow down oxidation and wear, extending the life of the aluminum sheets.

What happens to mirror aluminum sheets in high-temperature environments?

In high-temperature environments, mirror aluminum sheets may experience the following changes:

- Discoloration: High temperatures can cause the surface of the aluminum sheets to discolor, affecting their reflectivity and aesthetics.

- Deformation: Excessive heat may lead to thermal expansion, causing shape changes or deformation.

Solution:

To avoid these issues, try to keep mirror aluminum sheets away from high-temperature environments. For applications that require high-temperature resistance, select aluminum alloys or surface treatments designed to handle elevated temperatures, ensuring both performance and appearance.

How to choose the right mirror aluminum sheet?

Type of Mirror Aluminum Sheet: Select the type based on application needs. Reflective aluminum sheets are suitable for applications that require high reflectivity but do not need high durability, while anodized aluminum sheets are better for applications requiring durability and scratch resistance.

Reflectivity: Different types of mirror aluminum sheets have different reflectivities. For instance, ultra-thin mirror aluminum typically has a reflectivity of up to 95%, which can significantly enhance light efficiency. Always check the reflectivity to ensure it meets the application requirements.

Thickness: Mirror aluminum sheets come in various thicknesses, so choose based on specific applications. Thicker mirror aluminum sheets are generally used for commercial and industrial purposes, while ultra-thin mirror aluminum is advantageous in terms of weight reduction and cost savings.

Size: Choose the appropriate size. Larger mirror aluminum sheets are generally used in large-scale commercial buildings or industrial applications like solar panels, while smaller sheets are more suitable for lighting, signage, etc.

Surface Treatment: Mirror aluminum sheets can be processed using various surface treatments such as polishing, embossing, and anodizing. Select the right surface treatment based on specific functionality and aesthetic requirements. For example, hammered embossed mirror aluminum is ideal for diffuse lighting, while anodized mirror aluminum is preferred for high-durability architectural facades.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote