Extra-wide aluminum plates refer to aluminum plates with a width exceeding 1500mm, typically used in industrial and construction applications that require large dimensions, such as aerospace, shipbuilding, architectural decoration, and transportation. Due to their large width, they reduce the need for splicing, offering greater structural integrity and aesthetic appeal.

Chalco has the capability to produce aluminum sheet coils up to 2600mm wide and aluminum plate up to 3000-4500mm wide. With our advanced production technology, including a 4+1 continuous rolling mill for rough and finish rolling, as well as innovative cross-rolling technology, we can offer a wide range of thicknesses and sizes. Welcome contact

Chalco ultra-wide aluminum plate sheet coil foil product type

Our extra-wide aluminum products offer a wide range of thicknesses and widths, including extra-wide aluminum plates, coils, and foils. Whether it's thick plates, thin coils, or large-width aluminum foils, we provide flexible sizes and specifications to meet diverse customer needs. With a rich inventory and strong production capacity, we are able to quickly respond to custom requirements and deliver high-quality extra-wide aluminum products.

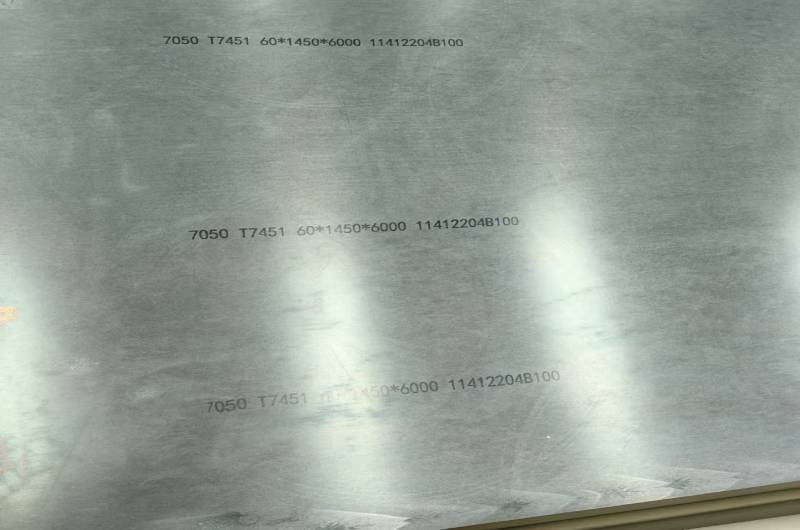

Ultra-wide aluminum plate

Extra-wide aluminum plates are those with a width greater than 1500mm, used in industries like aerospace, shipbuilding, architecture, and transportation. Their large width reduces the need for splicing, improving structural integrity and aesthetics.

Contact us now- Max width: 3000mm; Cross-rolling up to 4350mm

- Common thickness: 4.5-100mm

- Common alloys: 6061, 7075, 2024, 7050, 5005, 5052, 5083, 5182, 5754, 1050, 1100, 3003, etc.

- Surface treatments: Coating, anodizing, electrophoresis, etc.

- Applications: Aerospace, shipbuilding, construction, transportation, etc.

Ultra-wide aluminum sheet coil

Extra-wide aluminum coils are roll-formed products made from aluminum plates, commonly used in applications requiring large width and lighter weight, offering greater processing flexibility.

Contact us now- Max width: 2650mm

- Common thickness: 0.2-6mm

- Common alloys: 1050, 1060, 1100, 3003, 3004, 3104, 2024, 5052, 5083, 6061, 7075, etc.

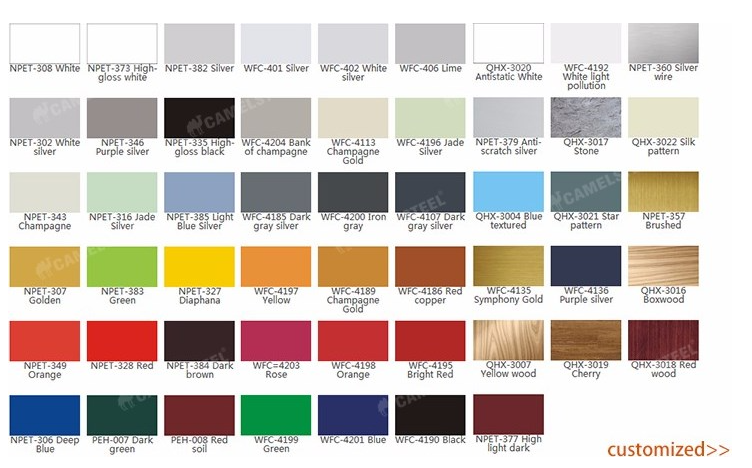

- Coating types: PE, PVDF, HDP, FEVE, etc. Colors customizable, single or double-sided coating

- Coating thickness: Standard 18-25 microns, maximum up to 60 microns

- Applications: Roofing materials, architectural facades, vehicle exteriors, etc.

Ultra-wide aluminum foil

Extra-wide aluminum foil is primarily used for thermal insulation, heat preservation, and other functional applications. It is designed in wide rolls for easy installation and large-area coverage.

Contact us now- Common width: 1000mm (912/914mm) or wider

- Common alloys: 1050, 1060, 1200, 1100, 8111, 8011, 8079, 3003, etc.

- Coating types: PE, PVDF, HDP, FEVE, etc. Colors customizable, single or double-sided coating

- Applications: Roof insulation, packaging industry, building and industrial insulation, etc.

Chalco's production and processing capacity for ultra-width aluminum plate sheet coil foil

Quality Assurance

- GJB 9001: National defense and military industry quality management system certification, meeting the quality requirements of military products.

- AS9100: Aerospace quality management system certification, ensuring products meet the stringent requirements of the aerospace industry.

- TS16949: Automotive industry quality management system certification, ensuring products meet the quality standards of automotive manufacturers.

- Nadcap: Non-destructive testing, heat treatment, and materials testing certification, ensuring product reliability in high-demand applications.

- DNV / ABS / LR Classification Society Certification: Applicable to the shipbuilding and marine engineering industries, ensuring that aluminum plates meet the strength and corrosion resistance standards required for ship construction.

- Online Testing Equipment: Including Alscan hydrogen analyzer, slag analyzer, etc., ensuring that each batch of products undergoes strict quality control to meet high standards.

Production Capacity

- 8 Melting and Casting Production Lines: Ensure high-quality aluminum alloy casting, capable of meeting large-scale production requirements.

- 1+4 Hot Rolling Production Line: With complete supporting facilities, capable of producing ultra-wide aluminum sheets and coils with a maximum width of 2650mm.

- Pre-Stretching Machine 125MN: Used for stretching aluminum sheets in T651 condition, with a maximum width of 4350mm, ensuring high strength and stability of the products.

- Cross-Rolling Technology: Employing advanced cross-rolling processes to improve the formability and surface quality of aluminum sheets.

- Supporting Equipment: Includes quality control and online testing equipment, such as Alscan hydrogen analyzer and slag analyzer, ensuring high product quality and consistency.

Processing Capabilities

- Precision Cutting: Providing accurate length cutting services to ensure aluminum sheets, coils, and foils meet customer specifications.

- Stamping and Punching: Using advanced stamping equipment to provide high-precision punching and perforating services, meeting complex design requirements.

- Bending Processing: Custom bending services for various industrial applications, ensuring aluminum products meet structural design requirements.

- Custom Sizes and Specifications: Flexible size customization according to customer requirements, ensuring aluminum products fit specific applications.

- Small-Batch Production: Offering small-batch and prototype development services to support customers' custom needs.

- Surface Treatments: Including anodizing, coating, electrophoresis, and other treatments to enhance durability, corrosion resistance, and aesthetics of aluminum products.

| Surface Treatment | Features | Common Applications | Common Colors | Common Coating Types |

| Coating | Controlled thickness, diverse colors, good corrosion resistance and aesthetics | Construction, appliances, automotive, industrial equipment | Various colors including red, blue, green, black, white | PE, PVDF, EPOXY, HDP, PTFE, LDPE, carbon coated, sliding lubricant |

| Anodizing | High surface hardness, good wear resistance and corrosion resistance, can be dyed, environmentally friendly | Aerospace, electronics, consumer goods, construction | Silver, black, gold, red, blue | None (natural oxide film formation) |

| Electrophoresis | Uniform coating, strong adhesion, good corrosion resistance, suitable for complex-shaped parts | Automotive, appliances, construction, electronics | Black, white, transparent, gold | Acrylic, polyurethane, epoxy, etc. |

Choose Chalco ultra-width aluminum plate sheet coil foil by alloy grade

Chalco offeres a variety of aluminum alloy coils with different alloys and coatings to meet the needs of different customers. Common alloys include 1050, 1060, 1100, 3003, 5052, 6061, 7075, 2024 and others, each with its unique properties and applications. If you have project requirements, please feel free to contact us, and we will provide you with customized solutions.

-

1050 aluminum alloy

High purity

Good corrosion resistance

Easy to process

-

1060 aluminum alloy

Excellent corrosion resistance

Good electrical conductivity

High formability

-

1100 aluminum alloy

Excellent corrosion resistance

Good workability

Lower strength

-

1200 aluminum alloy

Good corrosion resistance

Easy to form

Lower strength

-

8011 aluminum alloy

Excellent corrosion resistance

Good formability

Low cost

-

5052 aluminum alloy

Excellent corrosion resistance

High strength

Good formability

-

5083 aluminum alloy

Exceptional corrosion resistance

High strength

Good weldability

-

3003 aluminum alloy

Good corrosion resistance

Excellent formability

Lower strength

-

5754 aluminum alloy

Excellent corrosion resistance

High strength

Good formability

-

6061 aluminum alloy

Good strength

Excellent weldability

Good corrosion resistance

-

2024 aluminum alloy

High strength

Good corrosion resistance (heat-treated)

Good machinability

-

7075 aluminum alloy

High strength

Good fatigue resistance

Moderate corrosion resistance

Your One-stop Solution—Explore Chalco ultra-wide aluminum products by industry applications

At Chalco, we offer a comprehensive, one-stop solution for ultra-wide aluminum products. With our advanced production capabilities and expert technical team, we provide tailored solutions to meet the diverse needs of various industries, including aerospace, automotive, construction, and more. Discover how our ultra-wide aluminum plates, coils, and foils can serve your project requirements.

Ultra-Wide aluminum plate for aerospace and aviation

Recommended Alloys: 2024, 2219, 6061, 6082, 7075, 7050, 5083...

Common Products: Large, thick aluminum plates for aircraft and aerospace components

Services:

- Custom thicknesses and dimensions to meet specific aerospace design requirements

- Precision cutting for large aerospace structures and components

- Heat treatment (e.g., T6, T73) for improved strength and fatigue resistance

- Surface treatment (anodizing, anti-corrosion coatings) for durability and performance

Ultra-wide aluminum coil for roofing & building facades

Recommended Alloys: 1050, 1060, 1200, 1100, 8111, 8011, 8079, 3003

Nominal Thickness: 0.021mm, 0.026mm, 0.03mm, 0.04mm, 0.05mm, 0.06mm, 0.07mm, 0.08mm, 0.1mm

Width: 20inch, 24inch, 48inch, 914mm, 912mm,

Environmental Certification:ISO 14001:2004; EU REACH; RoHS Directive; ISO Certifications Conforms to international standards including DIN, ASTM, BS, EN, and ECCA.

Services:

- Custom slitting and cutting to fit project specifications

- Surface coatings (PVDF, PE) for weather resistance and aesthetics

- Customized Color: Terracotta, White, Black, Blue, Green

- Lacquered: One side or both sides

- Lightweight solutions for easy handling and installation

- Flexible roll lengths and widths for large-scale projects

Ultra-Wide aluminum plate & coil for automotive & transportation

Recommended Alloys: 5052, 3003, 5083

Common Products: Wide aluminum plates and coils for vehicle bodies, trailers, and transport containers

Hot selling size: 48''*96'' 48''*120'' 48''*110'' 49''*96'' 4'*8'

Color coated: white, black, red

Services:

- Custom bending for vehicle body structures and transportation parts

- Lightweight solutions for improved fuel efficiency

- Surface coating for corrosion resistance and visual appeal

- Small-batch and prototype development for automotive applications

-

5052 wide sheet coil for the outer skin of box car

5052 wide sheet coil for the outer skin of box carCompared with 3003, 5052 offers superior corrosion resistance and mechanical properties, along with better color coating and coloring performance, making it ideal for use as the outer skin of box trucks, RVs, and refrigerator cars.

-

3003 ultra wide aluminum sheet coil for inner skin of van

3003 ultra wide aluminum sheet coil for inner skin of van3003 aluminum sheet coil's high surface smoothness makes it ideal for inner linings in box trucks, while its painted version is widely used in construction for roof and wall panels, ceilings, and corrugated panels, offering good thermal insulation and refrigeration.

-

5083 aluminum sheet coils for trucks, tank trucks, and refrigerated trucks

5083 aluminum sheet coils for trucks, tank trucks, and refrigerated trucksThe excellent weldability and formability of 5083 ultra-wide aluminum coils make them easier to process and connect during truck and refrigerated truck manufacturing, and suitable for complex processing like deep drawing and bending, commonly used in truck body and tank body manufacturing.

Ultra-Wide aluminum foil for insulation

Recommended Alloys: 1050, 1060, 1200, 1100, 8111, 8011, 8079, 3003,

Common Products: Wide aluminum foil for thermal insulation and packaging applications

Common width: about 1000mm(912/914mm), or more.

Services:

- Custom Widths and Thicknesses: Tailored solutions for thermal insulation materials to meet specific project needs.

- Surface Coating: Coating options to enhance durability, heat resistance, and performance in challenging environments.

- Material Composites: Chalco provides composite solutions by laminating aluminum foil with other materials like polyethylene (PE), polyester (PET), or foam for enhanced thermal insulation. These composite foils are ideal for high-efficiency insulation in construction, HVAC, and automotive applications.

| Chalco aluminum roof insulation types and their application fields | |||

| Aluminum foil type | Properties | Main areas of application | Advantages |

| Standard aluminum foil | Non-perforated, reflective | General roof and wall insulation | High heat reflection, cost-effective |

| Perforated aluminum foil | Perforated, permeable to air | Roof insulation to prevent condensation | Prevents mold, allows air circulation |

| Air foil with bitumen lamination | Bitumen layer, protective | Basement walls and areas susceptible to moisture | Additional protection against moisture and damage |

| Aluminum composite film | Laminated with plastic, tear-resistant | Industrial applications, large insulation projects | Increased tear resistance, easy handling |

| Alu-polyester foil | PET-coated, durable | Packaging industry, protective insulation | Protection against environmental influences, durable |

Ultra-Wide aluminum plate for marine & offshore engineering

Recommended Alloys: 5083, 5086, 5754

Common Products: Corrosion-resistant aluminum plates for marine structures, ships, and offshore platforms

Services:

- Customized alloys to withstand saltwater corrosion

- Precision cutting for marine vessel components

- Heat treatment for enhanced strength and fatigue resistance

- Easy packaging and transport for offshore installations

Ultra-Wide aluminum foil for industrial manufacturing

Recommended Alloys: 1100, 1060, 3003

Common Products: Aluminum foil for industrial processes, heat exchangers, and machinery parts

Services:

- Precision cutting and slitting for industrial applications

- Surface treatments to enhance durability and corrosion resistance

- Tailored solutions for heat exchangers and industrial machinery

- Custom foil dimensions and forms to meet specific process requirements

Properties reference table of Chalco ultra-width aluminum sheet coil

| Properties reference table | |||||

| 3003 Alloy | 5052 Alloy | 5754 Alloy | 5083 Alloy | 5182 Alloy | |

| Brinell Hardness | 28-65 | 46-83 | 52-88 | 75-110 | - |

| Elastic Modulus GPa | 70 | 68 | 68 | 68 | 68 |

| Elongation at Break % | 1.1-28 | 1.1-22 | 2.0-19 | 1.1-17 | 1.1-12 |

| Fatigue Strength MPa | 39-90 | 66-140 | 66-140 | 93-190 | 100-130 |

| Shear Strength MPa | 68-130 | 120-180 | 120-190 | 170-220 | 170-240 |

| Tensile Strength: Ultimate MPa | 110-240 | 190-320 | 200-330 | 290-390 | 280-420 |

| Tensile Yield Strength: MPa | 40-210 | 75-280 | 80-280 | 110-340 | 130-360 |

| Performance parameters table for Chalco color coated aluminum coil | ||

| Property | Method | paint |

| Top layer | Coloured lacquer, polyester, PE | |

| Aluminium | 8011/8079/1200/1100/1060 O | |

| Bottom layer | Coloured lacquer, polyester, PE | |

| Standard colours | Wide range of colours RAL | |

| Bending | ECCA 7(0≤T BEND ≤1) | OK |

| Curing | Resistance to MEK | > 50 d.f. |

| Heat Resistance | 240 ℃/2 min. | OK |

| Corrosion Resistance( Neutral Salt Spray) | ASTM B117 (NaCI 5%/35℃ | >500h(According to specification >1000h) |

| U.V. Resistance | ASTM G154(500 h., ; UV -313 4h.60℃/Condensation 4h.40℃) | OK |

Other large size products in Chalco

500-1000mm aluminum tube

Ultra large diameter aluminum bar

Spiral welding aluminum tube pipe

1528mm aluminum tube pipe

Ultra thick aluminum block

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote