7075 aluminum flat bar is a high-strength aluminum alloy that offers steel-like strength while maintaining the lightweight advantages of aluminum. With excellent fatigue resistance and mechanical stability, it is a preferred material for aerospace structural components, high-performance automotive parts, mold bases, and other high-stress structural applications.

Compared with standard aluminum alloys, the tensile strength of 7075 aluminum flat bar exceeds 540 MPa. Tempers such as T73 and T7351 provide enhanced corrosion resistance, making it suitable for harsh environments such as marine, aerospace, and high-humidity applications.

Chalco supplies 7075 aluminum flat bars that comply with EN 755, ASTM B211, AMS 4122, AMS 4123, and offers custom sizes, tempers, and surface treatments tailored to your application needs.

Hot-Selling 7075 Flat Bar Sizes

7075 T651 Aluminum Flat Bar – Popular Sizes

Specification: AMS-QQ-A-200/9, AMS 4123

| Product Details | Thickness | Width |

| 7075 T651 aluminum flat bar - cold finished | 1/2" | 3/4" |

| 7075 T651 aluminum flat bar - cold finished | 1/2" | 1" |

| 7075 T651 aluminum flat bar - cold finished | 1/2" | 1-1/2" |

| 7075 T651 aluminum flat bar - cold finished | 1/2" | 2" |

| 7075 T651 aluminum flat bar - cold finished | 1/2" | 2-1/2" |

| 7075 T651 aluminum flat bar - cold finished | 1/2" | 3" |

| 7075 T651 aluminum flat bar - cold finished | 1/2" | 4" |

| 7075 T651 aluminum flat bar - cold finished | 3/4" | 1" |

| 7075 T651 aluminum flat bar - cold finished | 3/4" | 1-1/2" |

| 7075 T651 aluminum flat bar - cold finished | 3/4" | 2" |

| 7075 T651 aluminum flat bar - cold finished | 3/4" | 3" |

| 7075 T651 aluminum flat bar - cold finished | 3/4" | 4" |

| 7075 T651 aluminum flat bar - cold finished | 1" | 1-1/4" |

| 7075 T651 aluminum flat bar - cold finished | 1" | 1-1/2" |

| 7075 T651 aluminum flat bar - cold finished | 1" | 1-3/4" |

| 7075 T651 aluminum flat bar - cold finished | 1" | 2" |

| 7075 T651 aluminum flat bar - cold finished | 1" | 2-1/2" |

| 7075 T651 aluminum flat bar - cold finished | 1" | 3" |

| 7075 T651 aluminum flat bar - cold finished | 1" | 3-1/2" |

| 7075 T651 aluminum flat bar - cold finished | 1" | 4" |

| 7075 T651 aluminum flat bar - cold finished | 1-1/4" | 1-1/2" |

| 7075 T651 aluminum flat bar - cold finished | 1-1/4" | 2" |

| 7075 T651 aluminum flat bar - cold finished | 1-1/4" | 2-1/4" |

| 7075 T651 aluminum flat bar - cold finished | 1-1/4" | 2-1/2" |

| 7075 T651 aluminum flat bar - cold finished | 1-1/4" | 3" |

| 7075 T651 aluminum flat bar - cold finished | 1-1/2" | 2" |

| 7075 T651 aluminum flat bar - cold finished | 1-1/2" | 2-1/2" |

| 7075 T651 aluminum flat bar - cold finished | 1-1/2" | 3" |

| 7075 T651 aluminum flat bar - cold finished | 1-1/2" | 4" |

| 7075 T651 aluminum flat bar - cold finished | 1-3/4" | 2" |

| 7075 T651 aluminum flat bar - cold finished | 2" | 2-1/2" |

| 7075 T651 aluminum flat bar - cold finished | 2" | 3" |

| 7075 T651 aluminum flat bar - cold finished | 2" | 3-1/2" |

| 7075 T651 aluminum flat bar - cold finished | 2" | 4" |

| 7075 T651 aluminum flat bar - cold finished | 2-1/4" | 2-1/2" |

| 7075 T651 aluminum flat bar - cold finished | 2-1/2" | 3" |

| 7075 T651 aluminum flat bar - cold finished | 2-1/2" | 4" |

| 7075 T651 aluminum flat bar - cold finished | 3" | 4" |

7075 T7351 Aluminum Flat Bar – Popular Sizes

Specification: AMS-QQ-A-200/9, AMS 4124

| Product Details | Thickness | Width |

| 7075 T7351 aluminum flat bar - cold finished | 0.25" | 1.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.25" | 1.5" |

| 7075 T7351 aluminum flat bar - cold finished | 0.25" | 2.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.25" | 3.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.25" | 4.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.25" | 6.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.375" | 1.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.375" | 1.5" |

| 7075 T7351 aluminum flat bar - cold finished | 0.375" | 2.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.375" | 3.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.375" | 4.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.375" | 6.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.5" | 1.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.5" | 1.5" |

| 7075 T7351 aluminum flat bar - cold finished | 0.5" | 2.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.5" | 3.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.5" | 4.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.5" | 6.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.625" | 1.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.625" | 1.5" |

| 7075 T7351 aluminum flat bar - cold finished | 0.625" | 2.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.625" | 3.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.625" | 4.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.625" | 6.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.75" | 1.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.75" | 1.5" |

| 7075 T7351 aluminum flat bar - cold finished | 0.75" | 2.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.75" | 3.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.75" | 4.0" |

| 7075 T7351 aluminum flat bar - cold finished | 0.75" | 6.0" |

| 7075 T7351 aluminum flat bar - cold finished | 1.0" | 1.5" |

| 7075 T7351 aluminum flat bar - cold finished | 1.0" | 2.0" |

| 7075 T7351 aluminum flat bar - cold finished | 1.0" | 3.0" |

| 7075 T7351 aluminum flat bar - cold finished | 1.0" | 4.0" |

| 7075 T7351 aluminum flat bar - cold finished | 1.0" | 6.0" |

| 7075 T7351 aluminum flat bar - cold finished | 1.25" | 1.5" |

| 7075 T7351 aluminum flat bar - cold finished | 1.25" | 2.0" |

| 7075 T7351 aluminum flat bar - cold finished | 1.25" | 3.0" |

| 7075 T7351 aluminum flat bar - cold finished | 1.25" | 4.0" |

| 7075 T7351 aluminum flat bar - cold finished | 1.25" | 6.0" |

| 7075 T7351 aluminum flat bar - cold finished | 1.5" | 2.0" |

| 7075 T7351 aluminum flat bar - cold finished | 1.5" | 3.0" |

| 7075 T7351 aluminum flat bar - cold finished | 1.5" | 4.0" |

| 7075 T7351 aluminum flat bar - cold finished | 1.5" | 6.0" |

| 7075 T7351 aluminum flat bar - cold finished | 2.0" | 3.0" |

| 7075 T7351 aluminum flat bar - cold finished | 2.0" | 4.0" |

| 7075 T7351 aluminum flat bar - cold finished | 2.0" | 6.0" |

| 7075 T7351 aluminum flat bar - cold finished | 2.5" | 3.0" |

| 7075 T7351 aluminum flat bar - cold finished | 2.5" | 4" |

7075 Flat Bar Specifications

Temper:7075-T6, T651, T73, T7351, T6511, T76511

Height:2-50mm

Width:10-200mm(up to 750 mm for extra-wide sizes)

Length:2m/3m/6m, Custom lengths available

Standards:EN 755, ASTM B221, AMS 4126, AMS 4131, AMS 4141

Certifications:ISO 9001, AS9100, NADCAP (HT & NDT)

Inspection Methods:Ultrasonic Testing (ASTM B594), Metallography, Mechanical Property Testing

Product Types of 7075 Aluminum Flat Bars

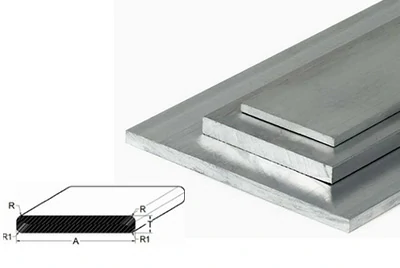

7075 aluminum Flat Bar-Flat Ends

These flat bars are either directly extruded or precision-cut, featuring square ends with no corner radius. Ideal for applications that require tight dimensional tolerances such as precision assembly, structural support, aerospace and mold tooling. Click to view available dimensions

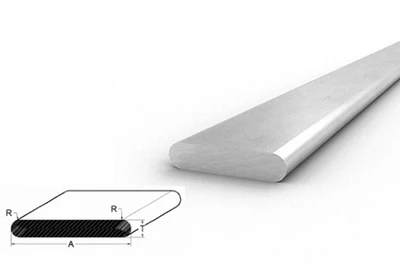

7075 aluminum Flat Bar-Radius Ends

Featuring a rounded corner profile, this bar type reduces stress concentration and improves fatigue resistance. It's widely used in aerospace components, racing chassis, and heavy-duty mechanical frames exposed to cyclic loads and vibrations. Click to view available dimensions

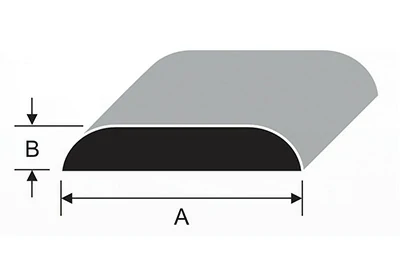

7075 Double Feathered Edge Flat Bar

Designed with dual tapered edge transitions, this type promotes uniform stress distribution and optimized fluid dynamics. Its enhanced mechanical performance and minimized need for post-processing make it suitable for high-precision machining, lightweight structural parts, sports equipment, and aerodynamic applications.

Chalco's Featured 7075 Aluminum Flat Bars

-

7075 Super Large Diameter Flat Bar

The 7075 super large diameter flat bar offers widths up to 750 mm, ideal for applications needing large, high-strength aluminum such as aerospace structures, large industrial molds, and rail transit components.

-

7075 Ultra-Precision Flat Bar

Produced via high-precision cold processing or grinding, the 7075 ultra-precision flat bar achieves ±0.02 mm tolerances, perfect for high-precision CNC machining, robotic joints, and aerospace instrument frames.

-

7075 Composite Flat Bar

This flat bar is clad with 1050 high-purity aluminum to boost corrosion resistance and conductivity, making it suitable for aerospace structural materials, electronic heat sinks, and weather-resistant applications.

-

7075 Pre-Drilled Flat Bar

Pre-drilled for fixed hole positions, the 7075 pre-drilled flat bar speeds up assembly and reduces secondary processing—ideal for aerospace fasteners, construction supports, and automation equipment.

Different Production Processes for 7075 Aluminum Flat Bars

-

7075 Extruded Aluminum Flat Bar

7075 Extruded Aluminum Flat Bar

Standard: AMS-QQ-A-200/11

Temper: 7075-O, 7075-T6510, 7075-T6511, 7075-T73, 7075-T73511

These extruded flat bars offer excellent dimensional stability and low internal stress. They are suited for high-strength structural parts, automotive chassis, rail transit components, and other applications with strict shape requirements.

-

7075 Cold Finished Aluminum Flat Bar

7075 Cold Finished Aluminum Flat Bar

Standard: AMS-QQ-A-200/9

Temper: 7075-T6, 7075-T651, 7075-T7351

Cold-finished flat bars, processed via cold drawing or cold rolling, have a higher surface finish, tighter tolerances, and more uniform mechanical properties compared to extruded products. They are ideal for precision machining, aerospace fasteners, and defense-grade parts.

-

Forged 7075 Aluminum Flat Bar

Forged 7075 Aluminum Flat Bar

Produced through forging, these flat bars have a denser internal structure, superior fatigue resistance, and higher impact toughness. They are widely used in high-load aerospace components, racing chassis, military equipment, and related applications.

-

Saw Cut 7075 Aluminum Flat Bar

Saw Cut 7075 Aluminum Flat Bar

These are produced by high-precision sawing of aluminum plates and can be customized to any required length and thickness, making them especially suitable for mold making, mechanical processing, and high-end equipment structures requiring specific dimensions.

Different Surface Finishes for 7075 Aluminum Flat Bars

7075 Polished Aluminum Flat Bar

7075 Anodized Aluminum Flat Bar

7075 Sandblasted Aluminum Flat Bar

Custom Tempering Options for 7075 Aluminum Flat Bars

Chalco offers a full range of heat treatment states for 7075 aluminum flat bars, including O, T6, T6511, T73, T73511, T76, and T76511—each with unique performance advantages and suitable applications. Below is a brief overview of the characteristics and standards for these different states:

-

7075-F Aluminum Flat Bar (Free Processing State) AMS 4186

7075-F Aluminum Flat Bar (Free Processing State) AMS 4186The F state is unheat-treated, preserving the original strength and ductility of the alloy. It is suitable for applications requiring subsequent heat treatment, forming, or machining.

High ductility Excellent machinability -

7075-O Aluminum Flat Bar (Annealed Soft State) ASTM B211, AMS 4187

7075-O Aluminum Flat Bar (Annealed Soft State) ASTM B211, AMS 4187The O state is fully annealed, offering the lowest tensile strength but the best elongation and formability.

Superior ductility Excellent formability Lower strength -

7075-T6 Aluminum Flat Bar (High Strength) ASTM B211, AMS 4154, AMS 4122

7075-T6 Aluminum Flat Bar (High Strength) ASTM B211, AMS 4154, AMS 4122The T6 state is achieved through solution heat treatment and artificial aging, reaching maximum strength. It is ideal for high-load and impact-resistant applications.

Extremely high strength Superior fatigue performance -

7075-T651 Aluminum Flat Bar (High Strength with Stress Relief) ASTM B211, AMS 4123

7075-T651 Aluminum Flat Bar (High Strength with Stress Relief) ASTM B211, AMS 4123The T651 state involves solution heat treatment, artificial aging, and stretching to relieve residual stress, yielding very high strength and excellent dimensional stability.

Extremely high strength Stress relief -

7075-T7351 Aluminum Flat Bar ASTM B211, AMS 4124

7075-T7351 Aluminum Flat Bar ASTM B211, AMS 4124The T7351 state is produced by extended over-aging, sacrificing some strength for markedly enhanced stress corrosion cracking (SCC) resistance and toughness.

Enhanced corrosion resistance High toughness -

7075-T6511 Aluminum Flat Bar (Stress-Relieved)

7075-T6511 Aluminum Flat Bar (Stress-Relieved)The T6511 state is obtained by stretching after T6 heat treatment to eliminate residual stress, providing excellent dimensional stability and rigidity.

Excellent stability High rigidity -

7075-T73 Aluminum Flat Bar (Enhanced Corrosion Resistance) ASTM B211, AMS 4166, AMS-QQ-A-200/11

7075-T73 Aluminum Flat Bar (Enhanced Corrosion Resistance) ASTM B211, AMS 4166, AMS-QQ-A-200/11The T73 state undergoes extended over-aging, trading some strength for improved corrosion resistance, making it suitable for high-humidity and salt-spray environments.

Superior SCC resistance -

7075-T73511 Aluminum Flat Bar (Corrosion Resistant + Stress Relief)

7075-T73511 Aluminum Flat Bar (Corrosion Resistant + Stress Relief)The T73511 state is a variant of T73 processed with additional extrusion and stress relief, yielding higher corrosion resistance and reduced processing stresses for long-term, high-humidity applications.

Superior SCC resistance -

7075-T76 Aluminum Flat Bar (Fatigue Resistance) ASTM B211, AMS-QQ-A-200/15

7075-T76 Aluminum Flat Bar (Fatigue Resistance) ASTM B211, AMS-QQ-A-200/15The T76 state optimizes the aging process on a T6 base to improve fatigue resistance while maintaining high strength, suitable for applications requiring long fatigue life.

Excellent fatigue resistance -

7075-T76511 Aluminum Flat Bar (Fatigue Resistance + Stress Relief) ASTM B221, AMS-QQ-A-200/15

7075-T76511 Aluminum Flat Bar (Fatigue Resistance + Stress Relief) ASTM B221, AMS-QQ-A-200/15The T76511 state refines T76 through extrusion and stress relief, improving stability and fatigue resistance—ideal for military aircraft frames, missiles, and high-speed train components.

Mechanical Properties of 7075 Aluminum Flat Bars

| Temper | Tensile Strength (Ksi) | Tensile Strength (MPa) | Yield Strength (Ksi) | Yield Strength (MPa) | Elongation (%) |

| 7075-O | - | - | 40 | 276 | 10% |

| 7075-T6 | 78 - 81 | 538 - 560 | 70 - 73 | 483 - 503 | 6-7% |

| 7075-T6510 | 78 - 81 | 538 - 560 | 70 - 72 | 483 - 496 | 6-7% |

| 7075-T6511 | 78 - 81 | 538 - 560 | 70 - 72 | 483 - 496 | 6-7% |

| 7075-T73 | 65 - 70 | 448 - 483 | 55 - 58 | 379 - 400 | 7-8% |

| 7075-T73510 | 68 - 70 | 469 - 483 | 58 - 61 | 400 - 421 | 7-8% |

| 7075-T73511 | 65 - 69 | 448 - 476 | 55 - 59 | 379 - 407 | 7-8% |

| 7075-T76 | 73 - 75 | 503 - 517 | 63 - 65 | 434 - 448 | 7% |

| 7075-T76510 | 74 - 75 | 510 - 517 | 64 - 65 | 441 - 448 | 7% |

| 7075-T76511 | 74 - 75 | 510 - 517 | 64 - 65 | 441 - 448 | 7% |

Features of 7075 Aluminum Flat Bars

- Ultra-high strength: Tensile strength up to 560 MPa, approaching that of high-strength steels.

- Excellent strength-to-weight ratio: Offers high strength while being much lighter than steel.

- Superior fatigue resistance: Stable performance under long-term loading and vibration.

- Corrosion resistance: T6 has lower corrosion resistance, but T73/T73511 tempering significantly improves resistance to stress corrosion cracking (SCC).

- Good machinability: Suitable for CNC precision machining; T6511 provides enhanced dimensional stability.

- Poor weldability: Prone to welding cracks; friction stir welding (FSW) or other specialized processes are recommended.

Typical Applications of 7075 Aluminum Flat Bars

7075 aluminum flat bars are widely used in fields with extreme strength requirements, such as aerospace, defense, rail transit, and high-end manufacturing. Some specific applications include:

Aerospace Applications

High strength, lightweight, fatigue resistant, and SCC resistant

Fuselage frames, skin reinforcement ribs

Engine mounts, turbine blade bases

Landing gear assemblies

Satellite support structures, rocket engine mounts

Defense and Military Applications

High strength, impact resistance, and extreme environment tolerance:

Military armored vehicle structures

M16 rifle receivers, rails, stocks

Missile frames, projectile structures

Military aircraft wing structures, ammunition mounts

Rail Transit Applications

High strength, fatigue resistance, and weight reduction

High-speed train chassis beams, body frames

Track support components

Train suspension assemblies

EMU braking systems

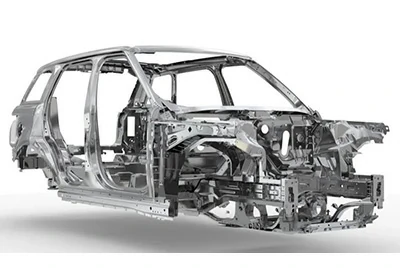

Automotive/Racing Applications

High rigidity, lightweight, impact resistance, and fatigue resistance

Racing chassis support structures, body frames

Lightweight racing wheels

Transmission components, suspension connectors

Motorcycle frames and swingarms

Marine Applications

Corrosion resistance, high strength, and lightweight

Naval vessel and high-speed boat structures Ship masts

Marine fasteners

Offshore drilling platform components

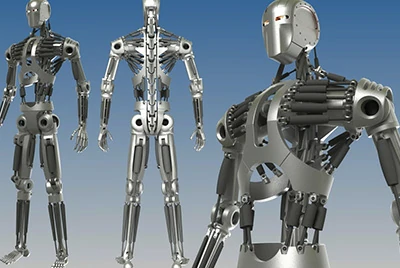

Electronics and High-End Manufacturing

High thermal conductivity, lightweight, and high-temperature resistance

5G base station heat sinks

Robotic frames

Precision instrument supports

Sports Equipment Applications

Lightweight, high strength, and impact resistance

High-strength racing frames

Ski bindings

Climbing carabiners and safety hooks

Professional glider components

What Can We Offer as a High-Quality Supplier of 7075 Aluminum Flat Bars?

- High-Quality Products: We use premium aluminum ingots and advanced extrusion techniques to ensure high strength, excellent mechanical properties, and superb dimensional stability.

- Exceptional Surface Quality & Precision Control: Our high-precision extrusion, online thickness measurement, and surface treatments guarantee smooth, even surfaces with no internal bubbles. Tolerances reach as tight as ±0.1 mm to meet high-precision machining needs.

- Multiple Temper Options: We offer various tempers such as 7075-T6, T6511, T73, T73511, T76, and T76511 for different strength, toughness, and corrosion resistance requirements.

- Fast Delivery & Customization: With a large inventory of standard sizes, we support quick shipments. We also provide custom services such as tailored lengths, precision cutting, pre-drilling, and anodizing to reduce downstream processing costs.

- Competitive Pricing: Leveraging large-scale production and an optimized supply chain, we offer cost-effective 7075 aluminum flat bars for both bulk and small orders.

- Strict Quality Testing: Every shipment undergoes rigorous quality tests—ultrasonic testing (UT), hardness tests, and chemical analysis in compliance with ASTM B221—and supports third-party certifications.

- Professional Technical Support & Customer Service: We provide technical consultation and material selection advice to help you choose the most suitable flat bar specifications and tempers. Our responsive after-sales team ensures a hassle-free purchasing experience.

More 7075 Products

- 7075 Aluminum Plates

- 7075 Aluminum Barss

- 7075 Aluminum Tubes

- 7075 Aluminum Extrusions

- 7075 Angle Aluminum

- 7075 Aluminum Blocks

6061 Aluminum Flat Bars vs. 7075 Aluminum Flat Bars

| Comparison Item | 7075 Aluminum Flat Bars | 6061 Aluminum Flat Bars |

| Main Alloying Elements | Aluminum-Zinc-Magnesium-Copper | Aluminum-Magnesium-Silicon |

| Tensile Strength | 78–81 ksi (538–560 MPa) | 45 ksi (310 MPa) |

| Yield Strength | 70–73 ksi (483–503 MPa) | 40 ksi (276 MPa) |

| Brinell Hardness | 150 HB | 95 HB |

| Elongation at Break | 7–10% | 12% |

| Shear Strength | 48 ksi (330 MPa) | 31 ksi (214 MPa) |

| Thermal Conductivity | 130 W/m·K | 170 W/m·K |

| Weldability | Poor, prone to cracking | Excellent, ideal for welded structures |

| Machinability | Moderate, requires high-performance tooling | Excellent, ideal for CNC machining |

| Corrosion Resistance | Low (T6 requires anodizing) | Excellent, suitable for outdoor use |

| Cost | Higher | Lower |

When to Choose 7075 Aluminum Flat Bars?

When you need extremely high strength (50–80% higher than 6061).

For high-load, high-impact applications such as aerospace, racing, and defense.

When lightweight and high rigidity are critical, e.g., drones, military equipment, racing chassis.

For parts experiencing heavy friction or high stress, such as firearm components and aircraft landing gear.

When to Choose 6061 Aluminum Flat Bars?

When excellent machinability is required for CNC processing and welding.

For outdoor or humid environments, e.g., ships, building frames, outdoor equipment.

In cost-sensitive projects where 6061 aluminum flat bars offer a more economical solution.

When a balance between strength and corrosion resistance is needed, such as truck frames and mechanical structures.

7075 Flat Bar Mold & Size Charts

7075 Square Flat Bar Size Chart

| Dim. A | Wall T | Radii R | Radii R1 | Lbs/Ft | Dim. A | Wall T | Radii R | Radii R1 | Lbs/Ft |

| 0.35 | 0.125 | 0.015 | 0.015 | 0.052 | 1.75 | 0.062 | 0.015 | 0.015 | 0.13 |

| 0.375 | 0.09 | 0.01 | 0.01 | 0.04 | 1.75 | 0.125 | 0 | 0 | 0.263 |

| 0.5 | 0.065 | 0.015 | 0.015 | 0.039 | 1.75 | 0.19 | 0.015 | 0.015 | 0.398 |

| 0.5 | 0.095 | 0 | 0 | 0.057 | 1.9 | 0.125 | 0.01 | 0.01 | 0.284 |

| 0.5 | 0.125 | 0.01 | 0.01 | 0.074 | 2 | 0.062 | 0.016 | 0.016 | 0.149 |

| 0.5 | 0.125 | 0.016 | 0.016 | 0.074 | 2 | 0.085 | 0 | 0 | 0.204 |

| 0.5 | 0.125 | 0.031 | 0.031 | 0.074 | 2 | 0.125 | 0.016 | 0.016 | 0.3 |

| 0.5 | 0.187 | 0 | 0 | 0.112 | 2 | 0.187 | 0 | 0 | 0.449 |

| 0.5 | 0.25 | 0.016 | 0.016 | 0.15 | 2 | 0.25 | 0.015 | 0.015 | 0.6 |

| 0.625 | 0.125 | 0 | 0 | 0.094 | 2 | 0.25 | 0.016 | 0.016 | 0.6 |

| 0.625 | 0.125 | 0.031 | 0.031 | 0.092 | 2 | 0.25 | 0.02 | 0.02 | 0.6 |

| 0.625 | 0.313 | 0.031 | 0.031 | 0.233 | 2 | 0.375 | 0.016 | 0.016 | 0.9 |

| 0.658 | 0.46 | 0.016 | 0.016 | 0.362 | 2 | 0.5 | 0.016 | 0.016 | 1.2 |

| 0.687 | 0.055 | 0 | 0 | 0.045 | 2 | 1.438 | 0.125 | 0.125 | 3.436 |

| 0.7 | 0.125 | 0 | 0 | 0.105 | 2.093 | 0.093 | 0.016 | 0.016 | 0.233 |

| 0.73 | 0.065 | 0.01 | 0.01 | 0.056 | 2.125 | 0.09 | 0 | 0 | 0.229 |

| 0.735 | 0.25 | 0.016 | 0.016 | 0.221 | 2.5 | 0.125 | 0.016 | 0.016 | 0.374 |

| 0.75 | 0.1 | 0.015 | 0.015 | 0.09 | 2.5 | 0.062 | 0.016 | 0.016 | 0.186 |

| 0.75 | 0.125 | 0.015 | 0.015 | 0.113 | 2.5 | 0.25 | 0.016 | 0.016 | 0.75 |

| 0.75 | 0.125 | 0.016 | 0.016 | 0.113 | 2.5 | 0.375 | 0.015 | 0.015 | 1.124 |

| 0.75 | 0.187 | 0.016 | 0.016 | 0.168 | 2.5 | 0.5 | 0.016 | 0.016 | 1.5 |

| 0.75 | 0.375 | 0.016 | 0.016 | 0.337 | 2.5 | 1.25 | 0.031 | 0.031 | 3.749 |

| 0.75 | 0.5 | 0.015 | 0.015 | 0.45 | 3 | 0.125 | 0 | 0 | 0.45 |

| 0.812 | 0.125 | 0.015 | 0.015 | 0.122 | 3 | 0.125 | 0.016 | 0.016 | 0.45 |

| 0.875 | 0.125 | 0 | 0 | 0.131 | 3 | 0.188 | 0.015 | 0.015 | 0.677 |

| 1 | 0.093 | 0.016 | 0.016 | 0.111 | 3 | 0.188 | 0.02 | 0.02 | 0.674 |

| 1 | 0.125 | 0 | 0 | 0.15 | 3 | 0.25 | 0.016 | 0.016 | 0.9 |

| 1 | 0.187 | 0 | 0 | 0.224 | 3 | 0.5 | 0.016 | 0.016 | 1.8 |

| 1 | 0.188 | 0.015 | 0.015 | 0.224 | 3 | 0.625 | 0.031 | 0.031 | 2.249 |

| 1 | 0.25 | 0.016 | 0.016 | 0.3 | 3 | 0.75 | 0.015 | 0.015 | 2.7 |

| 1 | 0.25 | 0.02 | 0.02 | 0.3 | 3 | 2 | 0 | 0 | 7.2 |

| 1 | 0.375 | 0.016 | 0.016 | 0.45 | 3.1 | 0.85 | 0.032 | 0.032 | 3.161 |

| 1 | 0.375 | 0.02 | 0.02 | 0.337 | 3.125 | 0.187 | 0.015 | 0.015 | 0.701 |

| 1 | 0.5 | 0.016 | 0.016 | 0.6 | 3.5 | 0.062 | 0.016 | 0.016 | 0.26 |

| 1 | 0.5 | 0.015 | 0.015 | 0.6 | 3.5 | 0.25 | 0.016 | 0.016 | 1.05 |

| 1.125 | 0.062 | 0 | 0 | 0.084 | 3.94 | 0.09 | 0 | 0 | 0.426 |

| 1.125 | 0.875 | 0.125 | 0.125 | 1.165 | 4 | 0.125 | 0 | 0 | 0.6 |

| 1.2 | 0.079 | 0 | 0 | 0.114 | 4 | 0.125 | 0.016 | 0.016 | 0.6 |

| 1.23 | 0.062 | 0.016 | 0.016 | 0.091 | 4 | 0.187 | 0.016 | 0.016 | 0.897 |

| 1.25 | 0.093 | 0.015 | 0.015 | 0.139 | 4 | 0.25 | 0.016 | 0.016 | 1.2 |

| 1.25 | 0.125 | 0.008 | 0.008 | 0.187 | 4 | 0.25 | 0.02 | 0.02 | 1.2 |

| 1.25 | 0.125 | 0.016 | 0.016 | 0.187 | 4 | 0.375 | 0 | 0 | 1.8 |

| 1.25 | 0.187 | 0 | 0 | 0.281 | 4 | 0.375 | 0.016 | 0.016 | 1.8 |

| 1.25 | 0.25 | 0.015 | 0.015 | 0.374 | 4 | 0.5 | 0.016 | 0.016 | 2.4 |

| 1.25 | 0.25 | 0.016 | 0.016 | 0.374 | 4 | 1 | 0.016 | 0.016 | 4.8 |

| 1.25 | 0.5 | 0.016 | 0.016 | 0.75 | 4.5 | 0.25 | 0.016 | 0.016 | 1.35 |

| 1.25 | 0.875 | 0.093 | 0.093 | 1.303 | 5 | 0.125 | 0.02 | 0.02 | 0.75 |

| 1.438 | 0.375 | 0 | 0 | 0.647 | 5 | 0.25 | 0.016 | 0.016 | 1.5 |

| 1.438 | 1 | 0.125 | 0.125 | 1.71 | 5 | 0.375 | 0 | 0 | 2.25 |

| 1.5 | 0.062 | 0.015 | 0.015 | 0.111 | 5 | 0.5 | 0.016 | 0.016 | 3 |

| 1.5 | 0.085 | 0.015 | 0.015 | 0.152 | 5.5 | 0.25 | 0.016 | 0.016 | 1.65 |

| 1.5 | 0.125 | 0.016 | 0.016 | 0.224 | 6 | 0.125 | 0 | 0 | 0.9 |

| 1.5 | 0.156 | 0.015 | 0.015 | 0.281 | 6 | 0.25 | 0.016 | 0.016 | 1.8 |

| 1.5 | 0.187 | 0 | 0 | 0.337 | 6 | 0.25 | 0.02 | 0.02 | 1.8 |

| 1.5 | 0.25 | 0.016 | 0.016 | 0.45 | 6 | 0.375 | 0 | 0 | 2.7 |

| 1.5 | 0.375 | 0.016 | 0.016 | 0.674 | 6 | 0.625 | 0 | 0 | 4.5 |

| 1.5 | 0.5 | 0.016 | 0.016 | 0.9 | 6 | 1 | 0.016 | 0.016 | 7.2 |

| 1.5 | 1.375 | 0.093 | 0.093 | 2.466 | 8 | 0.5 | 0.016 | 0.016 | 4.8 |

| 1.625 | 1.125 | 0.125 | 0.125 | 2.178 |

7075 Round Corner Flat Bar Size Chart

| Dim. A | Wall T | Radii R | Lbs/Ft | Dim. A | Wall T | Radii R | Lbs/Ft |

| 0.343 | 0.06 | 0.03 | 0.024 | 1.25 | 0.156 | 0.078 | 0.228 |

| 0.437 | 0.06 | 0.03 | 0.03 | 1.5 | 0.25 | 0.125 | 0.434 |

| 0.56 | 0.184 | 0.092 | 0.115 | 1.81 | 0.05 | 0.025 | 0.108 |

| 0.75 | 0.125 | 0.063 | 0.108 | 2 | 0.25 | 0.125 | 0.584 |

| 0.75 | 0.125 | 0.063 | 0.108 | 2 | 0.313 | 0.156 | 0.725 |

| 0.75 | 0.186 | 0.093 | 0.161 | 2 | 0.4 | 0.2 | 0.919 |

| 1 | 0.063 | 0.031 | 0.074 | 2.25 | 0.09 | 0.045 | 0.241 |

| 1 | 0.09 | 0.045 | 0.106 | 3.25 | 0.187 | 0.094 | 0.72 |

| 1 | 0.094 | 0.047 | 0.11 | 5.5 | 0.375 | 0.188 | 2.439 |

| 1 | 0.188 | 0.094 | 0.216 |