Chalco is a top aluminum processor with advanced equipment, including a 12, 500-ton extrusion machine and first "1+4" hot continuous rolling line, ensuring premium quality and efficiency.

With cutting-edge tools and certifications like AS9100 and ISO 9001, we offer customized aluminum bar solutions, including flaw detection, sawing, and milling, meeting AMS B211 and EN755-9-2008 standards.

Chalco aluminum bar product list

At Chalco, we take pride in offering an extensive range of aluminum rod products to meet diverse industrial needs. Our inventory includes extruded bar, cold-drawn bar, Aluminum-lithium alloy rod bar, precision-ground bar, forged bar, cast bar, aluminum billet, large-diameter aluminum bar, and specialized busbar;

With such a wide variety, we are equipped to provide solutions for applications spanning construction, transportation, electrical engineering, and high-performance industries.

Chalco extruded aluminum bar products

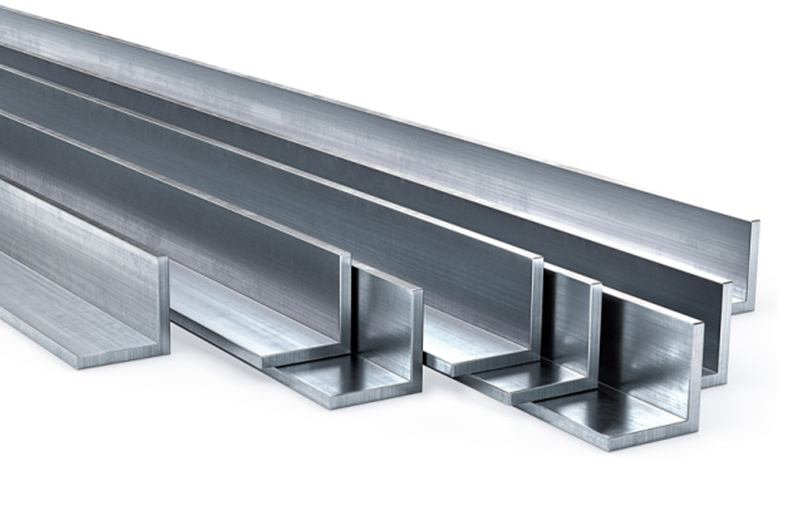

Aluminum Extruded Bar Rod is one of Chalco Aluminum's high-quality products, produced using advanced extrusion machines with capacities ranging from 550 to 2200 tons, all controlled by a PLC system for precision and consistency. Chalco can produce rods from various alloys, including 2024, 2014, 2017A, 2618, 5083, 6061, 7075, and more. These rods are widely used in industries such as aerospace, automotive, and construction, offering excellent strength, durability, and corrosion resistance for high-performance applications.Quick Quote

Hot selling aluminum alloys

6061 t4 t6 t651 extruded aluminum bar

6063 t4 t6 t651 extruded aluminum bar

6082 t4 t6 t651 extruded aluminum bar

7075 t73 t73511 t6511 extruded bar

7150 t77511 extruded bar

2024 T3 T4 T351 T3511 T8511 extruded aluminum bar

-

Aluminum extruded round bar

-

Aluminum extruded hex bar

-

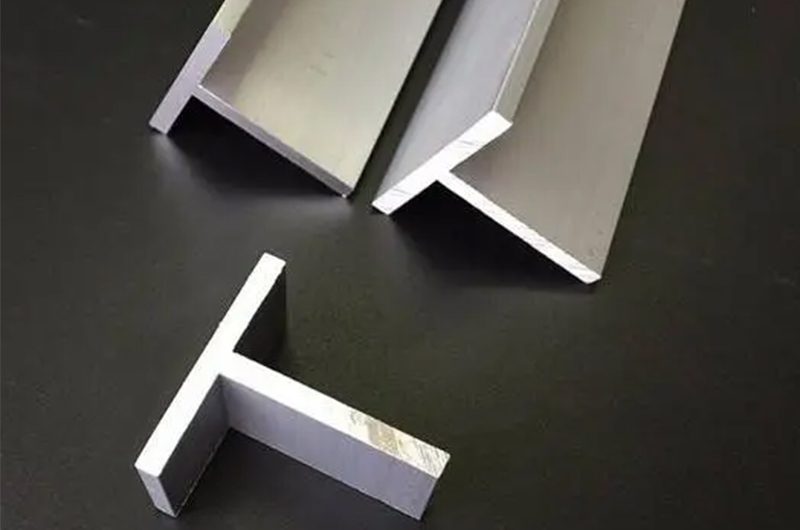

Aluminum extruded T-bar

-

Aluminum extruded Z-bar

-

Aluminum extruded H-bar

-

More customized shapes

Chalco cold finish aluminum (cold drawn) bar products

Cold-finished aluminum bars in Chalco feature a tolerance of less than -0.03mm, straightness within 0.3mm/m, and roundness of 0.01mm. The material consistency is excellent, with chamfered ends to prevent jamming. These bars are ideal for applications with moderate tolerance and diameter requirements, particularly suitable for CNC machines with spindle speeds exceeding 5000 RPM.Quick Quote

Cold-Finished (CF) Aluminum Bars are produced using a cold drawing process, with repeated drawing to achieve the desired diameter. This multiple-drawing technique ensures an exceptionally smooth surface and high precision.

-

6061 O T4 T6 T651 cold drawn bar

-

6063 T4 T6 T66 Cold Drawn (CF) Rod Bar

-

7075 O, F, T6, T651, T7351 Cold Drawn (CF) Rod Bar

-

5052 TF, O, H111, H14, H16 Cold Drawn (CF) Rod Bar

-

2024 T351, T851, T4 CF Rod Bar

-

2011 T3 Cold Drawn (CF) Rod Bar

-

2017 T3, T351, T4, T451, T6, T651 Cold Drawn (CF) Aluminum Rod Bar

-

2618 Cold Drawn (CF) Aluminum Rod Bar

Chalco Aluminum-lithium alloy rod bar

As a representative of next-generation lightweight materials, aluminum-lithium alloy rods are widely used in high-end fields such as aerospace, defense, and high-performance transportation, for manufacturing critical components like aircraft structures, spacecraft parts, and missile casings. Their outstanding mechanical and processing properties not only meet the rigorous demands of extreme environments but also enable more efficient and advanced engineering designs, fully demonstrating the exceptional value of high-end materials.Quick Quote

Aluminum-lithium alloy is a high-performance alloy that incorporates lithium into aluminum-based materials. It features low density, high specific strength, high specific stiffness, and excellent corrosion resistance, making it an ideal lightweight material for aerospace, defense, and military applications.

-

2219 Aluminum-Lithium Alloy Bar

Renowned for high-temperature performance and weldability, it is widely used in aerospace fuel tanks and structures.

-

2050 Aluminum-Lithium Alloy Bar

Renowned for its outstanding weldability and high strength, it is ideal for aircraft wings and large structural parts.

-

2070 Aluminum-Lithium Alloy Bar

Combines high specific strength and excellent corrosion resistance, making it a perfect choice for lightweight aerospace structures.

-

2090 Aluminum-Lithium Alloy Bar

Famous for its exceptional stiffness and low density, it is extensively used in aerospace frames and skin components.

-

2075 Aluminum-Lithium Alloy Bar

Offers superior fatigue performance and damage tolerance, suitable for high-reliability aerospace structures.

-

8090 Aluminum-Lithium Alloy Bar

Offers high strength, stiffness, and corrosion resistance, ideal for lightweight aerospace and defense components.

Chalco precision ground aluminum rod bar

Chalco's precision ground aluminum rods feature a diameter tolerance of less than -0.02mm, straightness below 0.2mm/m, and true roundness of 0.005mm. The material exhibits excellent consistency, and the double-ended chamfering ensures smooth machining without material jamming. These rods are particularly suitable for applications with strict tolerance and diameter size requirements, especially in the utilization of Swiss-type CNC machines with spindle speeds exceeding 8000.Quick Quote

Chalco aluminum forged bar products

Hot selling alloy: 2A01 2A02 2A10 2A11 2A12 3A21 3003 3004 3005 5A02 5A03 5A05 5B05 5A06 5050 5052 5056 5086 6A02 61016005 6063 6061 6082 7A04.

The organizational structure is relatively dense and less prone to internal defects; widely used for processing components with high strength requirements and high wear resistance. Chalco aluminum forged rod with a maximum diameter of 650mm.Quick Quote

Chalco aluminum billets

The shape and size are more flexible, but usually have lower density. Suitable for occasions with low density requirements and flexible shape and size requirements. The max. diameter of Chalco aluminum cast bar can reach 1350mm.Quick Quote

Chalco large diameter aluminum bar

Large diameter aluminum bars-up to 1350mm have many specialized applications in today's manufacturing market. Various industries such as aerospace, semiconductors, tire manufacturing, defense, and casting markets require the large cross-section circular aluminum alloys for key projects. And the ability to produce large size products has become a key indicator for measuring the capacity of an aluminum company.Quick Quote

Chalco aluminum busbar

Chalco aluminum busbars are crafted from high-conductivity metals like copper or aluminum. Copper excels in conductivity and thermal performance, while aluminum is ideal for lightweight and cost-sensitive applications. Coatings like tin or silver can be applied to enhance durability and conductivity.Quick Quote

Aluminum bar rod material selection

1000 Series (Pure Aluminum Rods)

With an aluminum content typically above 99%, these rods feature excellent corrosion resistance and electrical conductivity. However, their strength is relatively low, making them suitable for conductive materials and chemical equipment.Quick Quote

-

1050 aluminum bar rod

Aluminum≥99.5; with high plasticity, corrosion resistance, good conductivity; Applied in reflective panels, chemical industry containers…

-

1060 aluminum bar

Aluminum≥99.6; with good elongation, tensile strength, plasticity, corrosion resistance, conductivity; Widely used in products with low strength…

-

1070 aluminum bar rod

Known for its high aluminum content (99.7%) and excellent conductivity, 1070 is ideal for electrical and chemical applications.

-

1350 aluminum bar rod

With superior electrical conductivity and flexibility, 1350 is widely used in power transmission and distribution systems.

-

1370 aluminum bar rod

Featuring exceptional conductivity and corrosion resistance, 1370 is perfect for high-performance electrical conductors.

-

1100 aluminum bar rod

Renowned for its excellent corrosion resistance, workability, and high purity, 1100 is a versatile choice for chemical and decorative applications.

2000 Series (Aluminum-Copper Alloy Rods)

With an aluminum content typically above 99%, these rods feature excellent corrosion resistance and electrical conductivity. However, their strength is relatively low, making them suitable for conductive materials and chemical equipment.Quick Quote

-

2024 aluminum bar

High strength hard aluminum, has good spot-welding performance, and is used in high strength situations.

-

2014 aluminum bar

Hard aluminum alloy with good thermal strength. Used for heavy-duty aircraft, structural and suspension system components.

-

2017 aluminum bar

Good cutting performance, high strength and excellent fatigue strength. When temperature is above 125 ℃, its strength is higher than 7075.

-

2618 aluminum bar

Good process performance during casting and pressure processing (whether it is forging, extrusion or rolling).

-

2011 aluminum bar

Due to the presence of low-melting point phases Pb7Bi3 and Bi in the alloy, high-speed cutting and large feed rate can be used.

-

2219 aluminum bar

High-strength alloy with excellent corrosion resistance and heat tolerance, making it ideal for aerospace and high-temperature applications.

3000 Series (Aluminum-Manganese Alloy Rods)

With an aluminum content typically above 99%, these rods feature excellent corrosion resistance and electrical conductivity. However, their strength is relatively low, making them suitable for conductive materials and chemical equipment.Quick Quote

-

3003 aluminum bar

corrosion-resistant, weldable, versatile for decoration, packaging, construction, transportation, aerospace...

4000 Series ( Aluminum-silicon Alloy Rods)

Aluminum 4000 series bars, aluminum-silicon alloys, offer excellent wear resistance, low thermal expansion, and high corrosion resistance, ideal for high-temperature and automotive applications.Quick Quote-

4032 aluminum bar

corrosion-resistant, weldable, versatile for decoration, packaging, construction, transportation, aerospace...

5000 Series (Aluminum-Magnesium Alloy Rods)

With an aluminum content typically above 99%, these rods feature excellent corrosion resistance and electrical conductivity. However, their strength is relatively low, making them suitable for conductive materials and chemical equipment.Quick Quote

-

5A06 aluminum bar

High corrosion resistance, beautiful anodized surface; is a famous marine and military alloy.

-

5052 aluminum bar

Adding magnesium, it has good formability and corrosion resistance; the most widely used type of rust resistant aluminum bar.

-

5083 aluminum bar

Rust prevention, corrosion resistance, and high fatigue resistance. Used for low load parts that require high plasticity and good weldability.

-

5A02 aluminum bar

Rust proof, high plasticity and good formability. Suitable for containers with high process plasticity requirements and good corrosion resistance.

-

5086 aluminum bar

Offer high strength, excellent corrosion resistance, and weldability, ideal for marine and transportation applications.

6000 Series (Aluminum-Magnesium-Silicon Alloy Rods)

With an aluminum content typically above 99%, these rods feature excellent corrosion resistance and electrical conductivity. However, their strength is relatively low, making them suitable for conductive materials and chemical equipment.Quick Quote

-

6061 aluminum bar

Medium strength, excellent processing and welding performance. The material is dense and flawless, making it easy to polish, and oxidize.

-

6063 aluminum bar

Excellent processing performance, corrosion resistance and anodizing effect; Widely used in profiles for building, fences, etc.

-

6082 aluminum bar

Can be strengthened by heat treatment; good formability, weldability, machinability, and corrosion resistance. Mainly used in mechanical structures.

7000 Series (Aluminum-Zinc Alloy Rods)

With an aluminum content typically above 99%, these rods feature excellent corrosion resistance and electrical conductivity. However, their strength is relatively low, making them suitable for conductive materials and chemical equipment.Quick Quote

-

7075 aluminum bar

Ultra hard aluminum, strength is high and far superior to soft steel. It is the preferred choice for aerospace and other high-strength industries.

-

7050 aluminum bar

Ultra high strength, high yield ratio, and high specific strength; becoming one of the most important structural materials in aerospace field.

Chalco aluminum rod size and inventory table

| Alloy | Shape | Diameter mm | Temper | Inventory mm |

| 1050 | Round | Diameter:3-350 | O, H112 | - |

| Square | Side length: 6-160 | - | ||

| Rectangle | Thickness:1-160 Width: 6-570 | - | ||

| Hexagon | Width:6-80 | - | ||

| 1060 | Round | Diameter:3-350 | O, H112 | 8, 10, 12, 13, 14, 15, 16, 18, 20, 22, 25, 28, 30, 32, 35, 38, 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 100 |

| Square | Side length:6-160 | - | ||

| Rectangle | Thickness:1-160 Width: 6-570 | - | ||

| Hexagon | Width:6-80 | - | ||

| 2A12 | Round | Diameter:3-350 | T3 T351 T4 T451 T6 T651 T6511 T7351 | 5 - 560 |

| Square | Side length:6-160 | - | ||

| Rectangle | Thickness:1-160 Width: 6-570 | - | ||

| Hexagon | Width:6-80 | - | ||

| 2A14 | Round | Diameter:3-350 | T3 T351 T4 T451 T6 T651 T6511 T7351 | 20, 30, 35, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 100, 110, 120, 130, 140, 150 |

| Square | Side length:6-160 | - | ||

| Rectangle | Thickness:1-160 Width: 6-570 | - | ||

| Hexagon | Width:6-80 | - | ||

| 2014 | Round | Diameter:3-350 | T3 351 T4 T451 T6 T651 T6511 T7351 | 20, 30, 35, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 100, 110, 120, 130, 140, 150 |

| Square | Side length:6-160 | - | ||

| Rectangle | Thickness:1-160 Width: 6-570 | - | ||

| Hexagon | Width:6-80 | - | ||

| 5052 | Round | Diameter:3-350 | O F H12 H14 H22 H24 H32 H34 H38 H111 H112 | 5, 6, 8, 10, 12, 13, 14, 15, 16, 18, 20, 22, 30, 32, 35, 38, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 100, 110, 120, 150, 160, 170, 180, 200 |

| Square | Side length:6-160 | - | ||

| Rectangle | Thickness:1-160 Width: 6-570 | - | ||

| Hexagon | Width:6-80 | - | ||

| 5083 | Round | Diameter:3-350 | T3 T351 T4 T451 T6 T651 T6511 T7351 | 14, 15, 16, 18, 20, 22, 25, 28, 35, 38, 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 100, 110, 120, 130, 140, 150, 160, 190, 200 |

| Square | Side length:6-160 | - | ||

| Rectangle | Thickness:1-160 Width: 6-570 | - | ||

| Hexagon | Width:6-80 | - | ||

| 6061 | Round | Diameter:3-350 | T3 T351 T4 T451 T6 T651 T6511 T7351 | 5-560 |

| Square | Side length:6-160 | - | ||

| Rectangle | Thickness:1-160 Width: 6-570 | - | ||

| Hexagon | Width:6-80 | - | ||

| 6063 | Round | Diameter:3-350 | T3 T351 T4 T451 T6 T651 T6511 T7351 | 5-200 |

| Square | Side length:6-160 | - | ||

| Rectangle | Thickness:1-160 Width: 6-570 | - | ||

| Hexagon | Width:6-80 | - | ||

| 6082 | Round | Diameter:3-350 | T3 T351 T4 T451 T6 T651 T6511 T7351 | 8-270 |

| Square | Side length:6-160 | - | ||

| Rectangle | Thickness:1-160 Width: 6-570 | - | ||

| Hexagon | Width:6-80 | - | ||

| 7075 | Round | Diameter:3-560 | T3 T351 T4 T451 T6 T651 T6511 T7351 | 5-560 |

| Square | Side length:6-160 | - | ||

| Rectangle | Thickness:1-160 Width: 6-570 | - | ||

| Hexagon | Width:6-80 | - |

Chalco aluminum bar rod customization solutions

Chalco offers a comprehensive range of aluminum bar customization services to meet the diverse needs of various industries. Our services include, but are not limited to, the following:

1. Size Customization: Aluminum bars can be customized in length, diameter, and tolerance according to customer requirements. We ensure high-precision products that meet strict dimensional standards.

2. Alloy Composition Customization: Tailor the alloy composition based on specific application requirements. We offer aluminum bars in all series from 1xxx to 7xxx, meeting demands for different strength, corrosion resistance, and machinability levels.

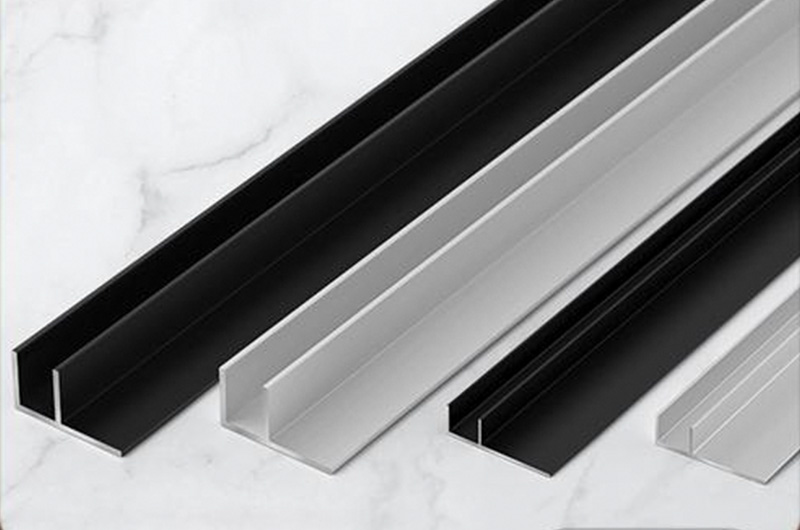

3. Shape Customization: Provide various shapes, including round bars, square bars, hex bars, T-bars, Z-bars, L-bars, and more, to suit different application scenarios.

4. Surface Treatment: Offer surface treatments such as anodizing, electroplating, and painting to enhance corrosion resistance and appearance, fulfilling both functional and decorative needs.

5. Heat Treatment: Services Provide heat treatment processes, such as quenching and aging, to enhance the mechanical properties and durability of aluminum bars based on application requirements.

6. Cutting Services: Perform precise cutting to customer-specified sizes or shapes, ensuring smooth, burr-free cutting surfaces suitable for precision machining or direct use.

7. Bending Services: Deliver professional aluminum bar bending services according to customer drawings or requirements, ensuring high accuracy and surface quality, ideal for structural and decorative applications.

8. Small Batch Customization: Support on-demand production for special projects or small-batch requirements, ensuring flexibility and cost-effectiveness.

9. Packaging and Logistics: Offer professional packaging services to ensure the safety of products during transportation, with global logistics support for prompt delivery to meet customer demands.

Whether it's for complex technical requirements or personalized designs, Chalco provides high-quality aluminum bar customization solutions.

Explore Chalco aluminum bars by industry applications——one stop solution for your project

At Chalco, you'll not only benefit from our extensive product inventory and advanced production customization capabilities but also from our expert technical team, who specialize in delivering comprehensive, one-stop solutions tailored to your project needs.

Aluminum bar for Aerospace Industry

- Recommended Alloys: 7075, 7050, 2024, 2219

- Common Products: High-strength extruded bars, large-diameter aluminum bars

- Services: Precision cutting for high-accuracy aerospace components Heat treatment (e.g., T6, T73) to enhance strength and fatigue resistance Surface treatment (anodizing, anti-corrosion coating) for durability

Aluminum bar for Automotive & Transportation

- Recommended Alloys: 6061, 6082, 5083, 4032

- Common Products: Cold-drawn bars, T-shaped bars, L-shaped bars

- Services: Custom bending to fit structural parts Surface coating to improve aesthetics and wear resistance Small-batch customization for prototype development

Aluminum bar for Construction & Structural Applications

- Recommended Alloys: 6063, 6061, 5086

- Common Products: Extruded bars, U-shaped bars, Z-shaped bars

- Services: Size customization to meet installation requirements Decorative surface treatments (anodizing, polishing) for aesthetics and durability Bending services for intricate architectural designs

Aluminum bar for Marine & Offshore Engineering

- Recommended Alloys: 5083, 5086, 5754

- Common Products: Corrosion-resistant extruded bars, large-diameter bars

- Services: Special alloy customization for saltwater corrosion resistance Cutting and packaging for easy transportation and installation Heat treatment to enhance fatigue strength

Aluminum bar for Electrical & Energy Industry

- Recommended Alloys: 1350, 1070, 1370

- Common Products: Busbars, cold-drawn bars

- Services: Precision cutting for perfect fit with equipment Surface plating (tin, silver) to improve conductivity and oxidation resistance Length customization to suit specific project requirements

Aluminum bar for Industrial Manufacturing

- Recommended Alloys: 6061, 6063, 5052

- Common Products: Cold-drawn bars, hexagonal bars, precision-drawn bars

- Services: Tolerance customization to meet high-precision machining needs Surface treatments (coating, anodizing) for enhanced corrosion resistance Small-batch customization for tooling and mold manufacturing

Aluminum bar for Decorative & Consumer Goods

- Recommended Alloys: 6063, 5052, 1100

- Common Products: Round bars, T-shaped bars, L-shaped bars

- Services: Polishing or electroplating for enhanced aesthetics Bending services to create intricate decorative designs Size customization to match product design requirements

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote