If you need an aluminum rod with high corrosion resistance, excellent ductility, and superior electrical conductivity, the 1100 aluminum rod is the perfect choice.

It meets the demands of high-standard manufacturing processes such as cold heading, deep drawing, welding, and bending, ensuring precision in your machining needs.

1100 aluminum rod specifications

- ASTM Standards: ASTM B211, ASTM B221

- EN Standards: EN573, EN 755

- IEC Standards: IEC 62004, IEC 60104, IEC 61089

- MIL & QQ-A Standards: QQ-A-225/1

- Certifications: ISO 9001, ISO 14001, RoHS, UL Certification

Popular 1100 Aluminum Rod Products

All 1100 aluminum materials provided by Chalco meet or exceed multiple specifications, including AMS, ASME, MIL-Spec, AWS, and SAE.

- Stock Diameter: 5mm-32mm (Custom sizes available)

- Temper: F/O/H/H14

- Coil Weight: 260KG (Adjustable per customer request)

- Tolerance: Based on ASTM B211, B221, or customer specifications

- Supply Forms: Spool, coil, straight rod

- Production Methods: Hot rolling, extrusion, cold drawing

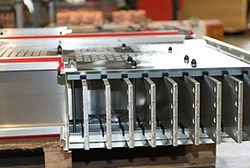

Hot Rolled 1100 Aluminum Rod

Chalco's hot-rolled aluminum rod has no joints in the middle and no coarse grain rings inside. It offers low cost, making it ideal for continuous cold heading production.

Contact us now

Extruded 1100 aluminum rod

Our extruded 1100 aluminum rod offers high precision, smooth surface, and supports various shapes like round, hexagonal, and square bars.

Contact us now1100 cold finished rod

High precision, smooth surface, and excellent machinability, ideal for precision parts.

Contact us now

1100 Aluminum Tig Rod

Offers excellent weldability, high purity, and corrosion resistance, ensuring strong and clean welds for aluminum fabrication.

Contact us nowFree cutting aluminum rod

Easy machining, reduced tool wear, and clean cutting, perfect for CNC processing.

Contact us now

Conductive aluminum rod

Provides high conductivity, low resistance, and corrosion resistance, ideal for bus bars, grounding rods, and electrical components.

Contact us now1100 aluminum rod size table

Here are the standard sizes of our 1100 aluminum rod, and we also offer customization options to meet your specific requirements.

Feel free to contact us for more details! Quick Quote

| Product | Diameter (mm) | Diameter (inch) | Tolerance (mm) |

| 1100 aluminum rod | 5 | 0.2 | ±0.05 |

| 1100 aluminum rod | 10 | 0.39 | ±0.05 |

| 1100 aluminum rod | 12.7 | 0.5 | ±0.05 |

| 1100 aluminum rod | 16 | 0.63 | ±0.1 |

| 1100 aluminum rod | 20 | 0.79 | ±0.1 |

| 1100 aluminum rod | 25 | 0.98 | ±0.1 |

| 1100 aluminum rod | 30 | 1.18 | ±0.1 |

| 1100 aluminum rod | 40 | 1.57 | ±0.2 |

| 1100 aluminum rod | 50 | 1.97 | ±0.2 |

| 1100 aluminum rod | 60 | 2.36 | ±0.3 |

| 1100 aluminum rod | 80 | 3.15 | ±0.3 |

| 1100 aluminum rod | 100 | 3.94 | ±0.3 |

| 1100 aluminum rod | 120 | 4.72 | ±0.5 |

| 1100 aluminum rod | 150 | 5.91 | ±0.5 |

Chemical Composition of 1100 Aluminum Rod (EN 573-3)

The 99% purity of 1100 aluminum rod ensures high corrosion resistance, excellent conductivity, and superior workability.

| Chemical Element | % Present |

| Si + Fe | 0.95 max |

| Cu | 0.05 – 0.20 |

| Mn | 0.05 max |

| Zn | 0.10 max |

| Other (Each) | 0.05 max |

| Others (Total) | 0.15 max |

| Aluminium (Al) | 99 % |

Physical properties of 1100 aluminum rod

| Performance | O | H14 | H112 |

| Density | 0.1 lb/in3 | 0.1 lb/in3 | 0.1 lb/in3 |

| Ultimate Tensile Strength | 13 ksi | 16-21 ksi | min. 12 ksi |

| Yield Tensile Strength | 5 ksi | 17 ksi | 5.2 ksi |

| Fatigue Strength | 5 ksi | 7 ksi | 4.6 ksi |

| Shear Strength | 9 ksi | 11 ksi | 7.8 ksi |

| Shear Modulus | 3, 770 ksi | 3, 770 ksi | 3, 770 ksi |

| Hardness Rockwell | Brinell | N/A | 23 | N/A | 32 | N/A | 23 |

| Elongation at Break Percentage | 32% | 1-10% | min. 14% |

| Modulus of Elasticity | 10, 000 ksi | 10, 000 ksi | 10, 000 ksi |

| Poisson's Ratio | 0.33 | 0.33 | 0.33 |

| Machinability Percentage | 10% | 30% | N/A |

| Melting Point | 1, 190-1, 215 °F | 1, 190-1, 215 °F | 1, 190-1, 210 °F |

| Specific Heat | 2.2 x 10^-1 BTU/lb-°F | 2.2 x 10^-1 BTU/lb-°F | 2.2 x 10^-1 BTU/lb-°F |

| Thermal Conductivity | 1, 560 BTU-in/hr-ft^2-°F | 1, 560 BTU-in/hr-ft^2-°F | 1, 560 BTU-in/hr-ft^2-°F |

| Electrical Conductivity | 59% IACS | 59% IACS | 59% IACS |

Advantages of 1100 aluminum rod

- High electrical conductivity, making it ideal for food processing, electrical, and chemical industries.

- Excellent cold working formability, allowing easy stamping, bending, and cold heading. Perfect for manufacturing rivets, stamped parts, and complex-shaped components.

- Low tool wear during turning and milling, ensuring a smooth surface finish and reducing precision part processing costs.

- Soft and highly ductile, providing exceptional forming capabilities for various applications.

- Superior welding performance, compatible with TIG and MIG welding, minimizing the risk of cracking.

- Outstanding corrosion resistance, excelling in humid, marine, and chemical environments.

- Customizable surface finishes, including mirror, sandblasted, and matte effects, with anodized color options such as black and gold.

- Lower raw material cost compared to other aluminum alloys, making it ideal for mass production of consumable parts like hardware and household items.

- Fully recyclable, supporting sustainable and eco-friendly manufacturing.

Applications of 1100 aluminum rod

- Busbars: utilizes the high electrical conductivity of 1100 aluminum (≥59% IACS) for power transmission components and connectors.

- Electronic heat sinks: processed into fins or rod bases for LED lights, power modules, and other heat dissipation applications.

- Terminal connectors: precision-machined into small conductive terminals, offering a cost-effective and lightweight alternative to copper.

- Rivets and bolts: excellent ductility and cold heading performance make it ideal for standard fastener production.

- Architectural decoration: used for window and door trim, providing lightweight and weather-resistant properties.

- Non-load-bearing automotive parts: applied in interior trim, wiring harness brackets, and other components to reduce vehicle weight.

- Battery connectors for electric vehicles: conductive connectors used in battery packs for new energy vehicles.

Technical selection recommendations:

| Application scenario | Recommended diameter (mm) | Surface treatment | Key advantages |

| Conductive components | 6-20 | Bright / passivated | High conductivity, reduced eddy current loss |

| Heat sinks | 10-30 | Anodized (black/natural) | Fast heat dissipation, oxidation resistance |

| Architectural decoration | 12-50 | Sandblasted/odized coloring | Aesthetic appeal, strong weather resistance |

| Hardware stamping parts | 6-40 | Raw material (subsequent coating) | Excellent ductility, low processing cost |

Precautions:

- Low strength (tensile strength ≈90MPa), not suitable for high mechanical load applications.

- Requires protective coating when exposed to strong acid or alkali environments for extended periods.

If you need 1100 Aluminum Rod for your application, please contact us.

We provide technical support and recommend the best product based on your specific needs. Quick Quote

Customer case study: improving cold heading quality and efficiency—hot rolled 1100 aluminum rod in high-end fastener production

Our customer is a high-end fastener manufacturer specializing in cold heading production for aerospace, high-speed rail, and automotive components.

After understanding their needs, we recommended hot rolled 1100 aluminum rod. Following trials and mass production, the customer reported significant improvements in product quality and production efficiency.

- Dense material structure: the hot rolling process refines the aluminum rod's internal grain structure, preventing structural instability caused by loose material composition.

- More stable cold heading formation: improved material uniformity eliminates defects such as orange peel, cracking, and hollow parts during cold heading. The product qualification rate increased by 30%.

- Reduced downtime and lower costs: hot rolled aluminum rods have no joint delamination issues, eliminating frequent production stoppages for defect inspection. Continuous cold heading production became smoother, improving efficiency by 20% and reducing material waste.

- Enhanced corrosion resistance and higher fastener quality: the high purity and uniform grain structure of the material provide superior oxidation and corrosion resistance, meeting the stringent standards of aerospace, high-speed rail, and automotive industries.

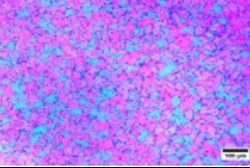

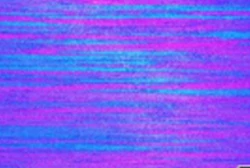

50mm hot rolled aluminum rod material structure:

No coarse grain rings

Uniform transverse grain structure

Streamlined longitudinal grain flow

Chalco's exclusive technology - hot rolling process

- Raw material preparation: select high-purity aluminum ingots.

- Peeling: remove surface impurities to enhance material purity.

- Heating: evenly control temperature for uniform heating.

- Rough rolling: perform initial deformation to optimize internal structure and increase density.

- Finishing rolling: further compression to improve dimensional accuracy.

- Annealing: relieve stress and enhance ductility and machinability.

- Drawing: precisely control dimensions, improving surface finish and mechanical properties.

- Final product: undergoes strict quality inspection to ensure high-quality hot rolled aluminum rods.

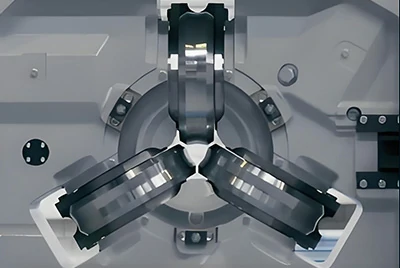

Using "2-roll + 3-roll rolling", multi-pass deformation refines the cast structure, enhancing mechanical properties.

Contact us now

Three-roll rolling applies an extremely favorable stress state inside the aluminum rod, with compressive stress surrounding the rolled material and acting radially toward its center.

This significantly reduces width spread, minimizing the impact of material width expansion differences. As a result, the material exhibits more uniform anisotropy, leading to smaller width spread and higher elongation.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quoteWhy choose us? — professional service, quality assurance

Strict quality control

All products comply with ASTM, EN, ISO, RoHS and other international standards, ensuring high purity, uniform structure, and stable performance.

We provide composition analysis, mechanical property testing, and microstructure analysis to ensure materials meet customer requirements.

Customized solutions

We offer custom diameters, lengths, and tolerances to meet diverse processing needs.

Multiple processing options, including hot rolling, extrusion, cold drawing, annealing, and surface treatments, optimize material performance.

Technical support is available to recommend the most suitable aluminum rod, reducing defects and improving yield rates.

Stable supply & fast delivery

With ample inventory and flexible production capacity, we fulfill bulk orders and urgent requests.

An efficient logistics system ensures fast global delivery, minimizing production downtime for customers.

Comprehensive testing services to ensure superior quality

Salt spray tester

Microstructure scanning electron microscope

Thermal simulation tester

Metallographic microscope

Optical emission spectrometer

Universal electronic testing machine

Equivalent specifications of 1100 aluminum rod

- AA1100

- UNS A91100

- Al99.0Cu

- NF 1100

- JIS A1100P

- 1050A

- A0(ГОСТ 11069-2001)

Packaging and transportation of 1100 aluminum rod

- Inner protection: Each aluminum rod is wrapped in PE film, with optional paper, cardboard, or foam layers for moisture and scratch resistance.

- Bundle securing: Aluminum rods are bundled and reinforced with steel or PET straps, with protective padding to prevent loosening and abrasion.

- Outer packaging: Bulk orders are packed in sturdy wooden crates or pallets, with optional export-grade fumigation and moisture-proof lining for compression and shock resistance.

- International shipping: Available by sea, air, or land, using professional shipping or air freight companies with optional container types for moisture and shock protection.

We provide professional packaging and secure transportation to ensure that high-quality 1100 aluminum rods arrive in perfect condition.

With Chalco, you can ship with confidence!

Choose the best aluminum material for your needs

| Alloy grade | Aluminum content (%) | Key characteristics |

| 1100 | ≥99.00 | High corrosion resistance, good weldability, excellent ductility, suitable for cold heading |

| 1050 | ≥99.50 | Higher conductivity than 1100, better ductility, ideal for electrical applications |

| 1060 | ≥99.60 | Higher conductivity (≈61% IACS), excellent oxidation resistance |

| 1070 | ≥99.70 | Higher purity, electrical conductivity up to 63% IACS, superior corrosion resistance |

| 1080 | ≥99.80 | Ultra-high conductivity, strong oxidation resistance, ideal for precision electronics |

| 1200 | ≥99.00 | Similar to 1100, excellent ductility, strong corrosion resistance |

| 1350 | ≥99.70 | Specially used for high-voltage electrical applications, low strength but excellent conductivity |

Related products of 1100 aluminum rod

Chalco supplies 1100 aluminum in various shapes and sizes, including foil, sheet, round bar, rod, plate, strip, and wire. For more information about 1100 aluminum alloy, contact us today! Quick Quote

1100 aluminum foil

1100 aluminum sheet

1100 aluminum plate

1100 aluminum tube

1100 aluminum wire

1100 aluminum bar

FAQs about 1100 aluminum rod

What is the minimum order quantity? Can you provide samples for testing?

Flexible MOQ, free samples available!

To meet different customer needs, our 1100 aluminum rod has a very flexible minimum order quantity. The exact MOQ can be negotiated based on specifications and stock availability.

How do you ensure reliability and on-time delivery? What is the delivery time?

Chalco is a reputable, well-established aluminum manufacturer with years of experience in aluminum processing. We have a comprehensive quality management system (ISO 9001 certified) to ensure strict quality control.

Delivery time depends on order quantity, specifications, and production schedule. We arrange production promptly upon receiving an order and deliver within the agreed contract timeframe.

What is the price of your 1100 aluminum rod? Do you offer discounts for bulk purchases?

Competitive pricing with better deals for bulk orders!

Chalco 1100 aluminum rod offers high quality at a competitive price. Bulk orders come with even greater advantages.

Is the material purity and composition of your 1100 aluminum rod guaranteed? Does it meet international standards?

Absolutely guaranteed!

Chalco's 1100 aluminum rod fully complies with AA 1100, EN AW-1100, and other internationally recognized standards.

How do you ensure the internal quality of 1100 aluminum rod? Will there be pores, impurities, or defects?

Chalco uses an exclusive hot rolling process with precise temperature and pressure control, along with multi-pass rolling, to refine the internal structure.

This process significantly enhances grain uniformity, increases material density, and effectively reduces or eliminates pores, inclusions, and looseness, ensuring top-quality aluminum rods.