Supplier of aluminum circle & disc

Chalco Aluminum is a source supplier of aluminum circle & disc, which is engaged in production, customization and processing. The product specifications are complete and the quality is stable.

We have four punch production lines, which produce aluminum rounds with good tensile properties, good oxidation properties, and no oil stains or scratches on the surface.

Specializing in the production of 1060, 1070, 3003, 5052 and other aluminum coil products with different alloys and temper. In addition, we can customize aluminum round production dies with different widths and diameters according to customer requirements.Quick Quote

Specification of Chalco Aluminum circle & disc

Common materials: 1060, 3003, 6061, 5052, 8011, 1050, 1070, 1100, 3004, 3105 and some other series. The most commonly used are 1060 and 3003 aluminum circle & disc.

Temper: O, H24, H18, H32, H34, H36, H38, H111, H112 hard , soft and tensile state can be customized

Thickness range: 0.02mm-12.00mm

Diameter range: 10mm-1000mm, support customized materials

Surface treatment: anodizing process, color coating, mirror reflection, enamel process.

Additional Services:it can be used for single-sided and double-sided film covering, paper adding, and other additional aluminum plate processes

Packaging: simple packaging, three-layer moisture-proof fine packaging, logistics packaging, foreign trade sea transportation packaging

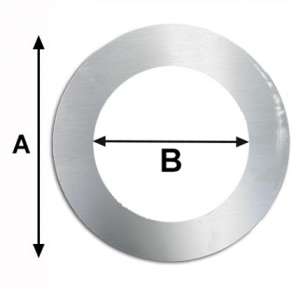

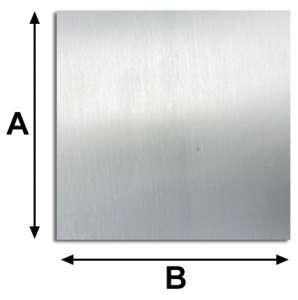

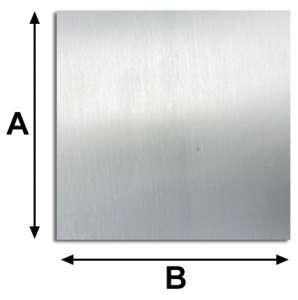

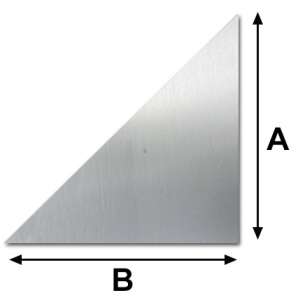

Popular Aluminum, Round, Ring, Gusset Products

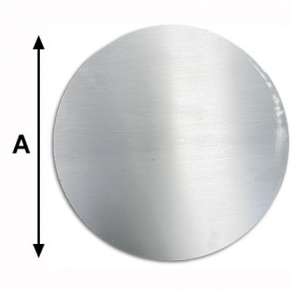

1/4" Thick - Aluminum Round Plate

1/2" thick - Aluminum Circle Plate

3/4" thick - Aluminum Circle Plate

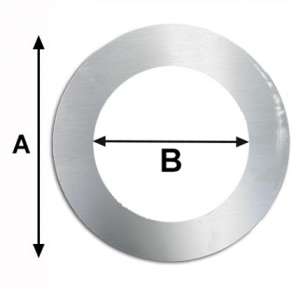

1/4" thick - Aluminum Ring Plate

1/2" thick - Aluminum Ring Plate

1/4" thick - Aluminum Square Plate

1/2" thick - Aluminum Square Plate

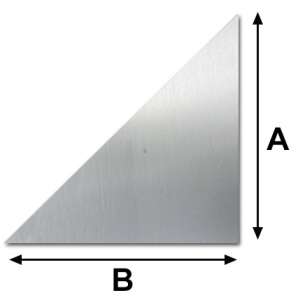

1/8" thick - Aluminum Gusset Plate

1/4" thick - Aluminum Gusset Plate

Stock of aluminum circle & disc

This is just common stock. Chalco also offers customizable aluminum discs with thickness ranging from 0.02 mm to 12.00 mm and diameters from 10 mm to 1000 mm.Quick Quote

| Description | Thickness (in) | Diameter (in) |

| Aluminum Circle Plate 1/4" thick | 1/4" thick | 4" |

| Aluminum Circle Plate 1/4" thick | 1/4" thick | 6" |

| Aluminum Circle Plate 1/4" thick | 1/4" thick | 8" |

| Aluminum Circle Plate 1/4" thick | 1/4" thick | 10" |

| Aluminum Circle Plate 1/4" thick | 1/4" thick | 12" |

| Aluminum Circle Plate 1/4" thick | 1/4" thick | 18" |

| Aluminum Circle Plate 1/4" thick | 1/4" thick | 24" |

| Aluminum Circle Plate 1/2" thick | 1/2" thick | 4" |

| Aluminum Circle Plate 1/2" thick | 1/2" thick | 6" |

| Aluminum Circle Plate 1/2" thick | 1/2" thick | 8" |

| Aluminum Circle Plate 1/2" thick | 1/2" thick | 10" |

| Aluminum Circle Plate 1/2" thick | 1/2" thick | 12" |

| Aluminum Circle Plate 1/2" thick | 1/2" thick | 18" |

| Aluminum Circle Plate 1/2" thick | 1/2" thick | 24" |

| Aluminum Circle Plate 3/4" thick | 3/4" thick | 4" |

| Aluminum Circle Plate 3/4" thick | 1/4" thick | 6" |

| Aluminum Circle Plate 3/4" thick | 3/4" thick | 8" |

| Aluminum Circle Plate 3/4" thick | 3/4" thick | 10" |

| Aluminum Circle Plate 3/4" thick | 3/4" thick | 12" |

| Aluminum Circle Plate 3/4" thick | 3/4" thick | 18" |

| Aluminum Circle Plate 3/4" thick | 3/4" thick | 24" |

| Aluminum Circle Plate 1/8" thick | 1/8" thick | 4" |

| Aluminum Circle Plate 1/8" thick | 1/8" thick | 6" |

| Aluminum Circle Plate 1/8" thick | 1/8" thick | 8" |

| Aluminum Circle Plate 1/8" thick | 1/8" thick | 10" |

| Aluminum Circle Plate 1/8" thick | 1/8" thick | 12" |

| Aluminum Circle Plate 1/8" thick | 1/8" thick | 18" |

| Aluminum Circle Plate 1/8" thick | 1/8" thick | 24" |

What are the uses of aluminum circle & disc?

Aluminum Slug

- Grade: 1100, 1050, 1060, 1070

- Temper: O-H112

- Diameter: 3mm-220mm

- Thickness: 0.5mm-25mm

- Surface Treatment: Polished, Mirror Polished, Brushed, Embossed, PE PVDF Coating, Teflon Coating

The aluminum slug complies with international standards such as EN 570/573, ROHS, SGS, etc. The surface treatment is uniform and smooth without burrs, edges, cracks, bark patterns, marks and oil stains.

Aluminum slugs are widely used in cosmetic packaging, capacitor housings, aerosol bottle aluminum plugs, hose aluminum blocks, auto parts, shoe polish tubes, aluminum cans, bottle caps, lighter housing aluminum heads and other fields.

Cookware aluminum circle & disc

Common product specifications of cookware Aluminum circle & disc:

- 2mm-3mm 1060 O, H12 cookware aluminum circle & disc suitable for frying pan, pizza pan and electric frying pan

- 2mm-4mm 3003 O aluminum circle & disc for electric pressure cooker and rice cooker

- 0.7mm-2mm 1100 O cookware aluminum circle & disc suitable for stock pots

- 3mm-5mm 1100 O aluminum disc is mainly used as the bottom of cooker and the bottom plate of stainless steel cooker

- 2mm-4mm 1100 3003 aluminum discs are used for coating cookware aluminum rings.

Lighting aluminium circle & disc

Lighting aluminium circle is mainly used to produce lampshade. It can also be used for embedded lighting, high shed industrial lighting, low shed industrial lighting, traffic light reflector and sports lighting.

Common product specifications of lighting aluminium circle & disc:

- 0.5-1.5mm 1100 O aluminium circle & disc: for ordinary lampshade

- 0.5-1.5mm 1100 O anodized aluminium circle & disc: good deep drawing quality. After bright dipping and anodizing, the semi mirror finish can be maintained. The minimum total reflectivity is 65%

- 0.5-5mm 1100 O coated aluminium circle & disc: used as coated aluminum lamp shade

Aluminum circle & disc for Road Sign

Currently, it is mainly used to supervise traffic signs, warning traffic signs, guidance signs, etc

Common alloy: 1100 H14

Natural surface: chemically degreased polished finish

Coil or sheet width: 2000 mm maximum

Thickness: can reach 6.0mm

Diameter: customizable Quick Quote

Spinning aluminium circle & disc

Our high-quality rotary aluminum discs are mainly used for lighting, ventilation, satellites, paint sprayers, central vacuum devices, filter cartridges, planters, waste containers, drip pans, low-temperature tank cars, racing wheels, etc.

What alloys are there in aluminum circle & disc?

aluminum circle and disc of 1000 series:

Alloy:1050, 1060, 1070, 1100

Features:aluminum content>99%, Excellent formability, high reflectivity, stable surface anodizing performance

Application:common cookers, extruded pot covers, aluminum pots, lamp accessories, lampshades, downlights, laminated lamps, street lamps, signs and building materials, traffic signs, curtain walls, ceilings

aluminum circle and disc of 3000 series:

Alloy:3003, 3004, 3005

Features:high elongation, can be used for deep drawing, high grain size, smooth surface, high reflectivity

Application:high grade cookers, sticky pans, pressure cookers, lamp accessories, signs and building materials

aluminum circle and disc of 5000 series:

Alloy:5052, 5754, 5083

Features:low material density, light weight of finished products, high tensile strength and elongation, and good fatigue strength

Application:Non stick pan, pressure cooker, pressure vessel, pressure cooker, etc.

aluminum circle and disc of 8000 series:

Alloy:8011

Features:excellent anodizing effect, stable performance and high surface quality

Application:can be made into pearl anodized cooker

What are the production processes of aluminum discs?

Stamping: Aluminum coils are punched into round sheets using a punching machine and a round die, which is suitable for efficient and low-cost mass production.

Shearing: Use shearing machine to cut aluminum plate into circular sheets, which is highly flexible and suitable for customized production.

Laser Cutting: Using laser cutting machine to accurately cut preset graphics, with high precision and good edge quality, suitable for cutting complex shapes.

Water Jet Cutting: Cutting with high-pressure water flow mixed with abrasives, no heat-affected zone, high cutting accuracy, suitable for cutting thick aviation plates.

Milling: Use a milling machine to partially mill the aluminum plate to form a circular sheet with high precision.

Spinning: Fix the aluminum disc on the spinning machine and gradually form it through the spinning tool. It is suitable for the production of lamp reflectors, kitchen utensils, and gas cylinder bottoms.

Punching: Use a punching machine to punch out multiple small discs on the aluminum plate. It is efficient and suitable for the production of small-sized aluminum discs.

Why is the quality of our aluminum discs second to none in China?

In order to ensure the quality of aluminum circle & disc, Chalco Aluminum sets up special quality inspection posts during the production process.

1. The surface of aluminum circle & disc

The aluminum circle & disc with good quality has no deformation, scratches, cracks, yellow spots, etc. And the surface color of high-quality aluminum circle is consistent. If there is color difference, the quality is unqualified.

2. Chemical composition:

The chemical composition of aluminum discs can be detected by professional spectrum analyzer. Then compare with the standard GB/T3880-2012 or ASTM B209. We must ensure that each chemical element is within the range required by the standard.

3. Mechanical properties

The tensile strength and mechanical properties of aluminum rounds are tested by a tensile testing machine to ensure that the tensile strength and elongation meet the standards. If the mechanical properties are not up to the standard, it is easy to break during the stamping and spinning process. It will waste a lot of time and material costs in production.

The tensile strength of aluminum circle & disc 1050-O is generally 60Mpa to 100Mpa; Elongation is about 35%. The tensile strength of aluminum circle & disc 1050 H12 is generally about 100Mpa, and the elongation is about 10%.

4. Particle size test

Different manufacturers have different requirements for grain size. According to international standards, most factories control the particle size above Grade II, while some large factories require the particle size to be Grade I. This can ensure that the yield of aluminum circle & disc reaches 98% or even 100% during the production of kitchenware.

Price quotation for aluminum circle & disc

Generally, the processing price of aluminum rounds varies according to different alloys and widths.We can process aluminum rounds according to the order quantity, and the price will also decline. We look forward to your consultation.

Price calculation method:

Hot rolled aluminum circle & disc price (yuan/ton)=aluminum ingot price+processing fee+freight

Packaging and transportation of aluminum circle & disc

1. Aluminum circle & disc are usually packed in a crossing girder way, and the packaging should meet the needs of storage and transportation.

2. During the transportation process, a layer of neutral or weak acid material shall be wrapped on the surface of aluminum foil roll and then put into the packing list.

3. The lap joint shall be fixed with adhesive tape and padded with soft cushion to protect the end face of aluminum foil roll.

4. Put desiccant in the roll and wrap it with plastic cloth. The sealing part of the outermost plastic cloth shall be firmly stuck with adhesive tape, and the remaining parts at both ends of the plastic cloth shall be inserted into the pipe core.

5. Finally, put the wrapped aluminum foil roll on the cross and fix it with steel tape, and then stick a case card on the end face of the aluminum foil roll.

6. Pay attention to the method of transportation, and handle with care when loading and unloading.