Among the many aluminum alloy materials, are you looking for aluminum coils with high strength, corrosion resistance and excellent processing performance? Chalco 6061 aluminum coils are your ideal choice! Relying on advanced production technology and strict quality control, we provide stable, high-performance, customizable 6061 aluminum coils to ensure excellent performance in high-demand industries such as aerospace, automotive manufacturing, architectural decoration, and electronic equipment.

Chalco 6061 aluminum coil has undergone precision rolling and heat treatment strengthening (T4, T6 and other states), and has excellent mechanical strength, good weldability, and outstanding surface treatment adaptability. It also supports a variety of deep processing of 6061 aluminum coil products, making your products more competitive in the market!

Chalco 6061 aluminum coil product overview

Alloy temper: 6061-O, 6061-T4, 6061-T6, 6061- T651 , 6061-T4 2 , 6061-T6 2

Thickness range: 0.2mm - 6.0mm (larger thickness can be customized)

Width range: 100mm - 2000mm (up to 2650mm ultra-wide roll)

Length: can be customized according to needs, support whole roll or cut processing

Surface treatment: smooth, anodized, coated, embossed, mirrored, punched, etc.

Specification: ASTM B209; ASTM B247; ASTM B483; AMS 4117, etc.

Chalco 6061 aluminum coil processing tempers

-

6061 O temper

The softest state has the highest ductility and easiest formability, suitable for bending, stamping and stretching.

-

6061 T4 temper

After solution heat treatment and natural aging, it has medium strength and good weldability.

-

6061 T6 temper

The most common high-strength state, after solution heat treatment + artificial aging, has excellent mechanical properties and corrosion resistance.

-

6061 T651 temper

Based on T6, tensile stress is eliminated to reduce processing deformation and is suitable for high-precision machining.

-

6061 T42 temper

Similar to T4, but allows T6 material to be re-dissolved and then naturally aged, providing more flexible manufacturing options.

-

6061 T62 temper

Similar to T6, but used with T4 material that is solution treated and then artificially aged, providing similar strength and corrosion resistance.

Chalco 6061 aluminum coil production and processing

As a basic material, 6061 aluminum coil usually needs further processing to meet the specific application requirements of different industries. For example, some industries require aluminum plates with high finish, while others require anti-slip and more weather-resistant surface treatment. Therefore, we provide a series of 6061 aluminum coil deep processing services to meet different usage scenarios.

6061 aluminum coil cutting

The aluminum coil leveling machine (Leveling & Cutting Machine) is used to unfold and flatten the 6061 aluminum coil and cut it into single aluminum sheets (Sheets) according to the required size.

Chalco can slit 6061 aluminum coils according to customer size requirements, ensuring surface flatness, no residual stress, and improving the accuracy of subsequent processing.

| Hot sale aluminum coil cutting thickness | |

| Thickness (mm) | Typical Applications |

| 0.3 - 1.0mm | Electronic housing, heat sink, decorative panel |

| 1.0 - 3.0mm | Chassis, car shell, aviation skin |

| 3.0 - 6.0mm | Mechanical parts, ship parts, rail transportation |

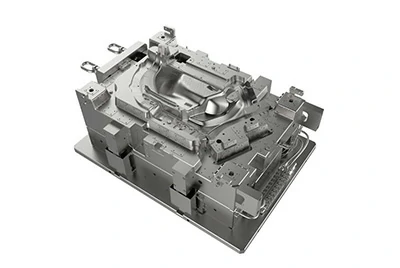

| 6.0 - 12.0mm | Moulds, machined parts |

| 12.0 - 25.0mm | High-strength structural parts, heavy machinery |

| 25.0mm or more | Special processing requirements (such as molds, aerospace parts) |

| Standard size cutting | |

| Dimensions (mm) | Industry Applications |

| 1000 × 2000 mm | General specifications, mechanical manufacturing, electronic products |

| 1220 × 2440 mm (4' × 8' standard board) | Building curtain wall and decoration industry |

| 1250 × 2500 mm | Automobile manufacturing, ship structure |

| 1500 × 3000 mm | Rail transportation, aerospace |

| 2000 × 4000 mm | Large equipment, special machinery |

Tips

- Customizable sizes: Some customers may require special sizes, such as extra-long boards (over 6m) or extra-wide boards (over 2m). Chalco extra-wide coils can be up to 2650mm wide.

- The maximum width of the coil after unrolling : usually limited by the original width of the aluminum coil (commonly 1000mm, 1220mm, 1500mm, 2000mm).

- The length can be cut as required , but for transportation and processing considerations, it generally does not exceed 6m (it can be 12m in special cases).

6061 aluminum coil slitting—6061 aluminum strip

Chalco uses high-precision slitting equipment to accurately cut 6061 aluminum coils into strips of different widths or coils of specific sizes along the length direction. The aluminum strips have extremely high dimensional accuracy and consistency, which can meet different processing requirements and support customized width, thickness and tolerance control, ensuring high-quality production and smooth connection with subsequent processing.

6061 aluminum strip product advantages

- High dimensional accuracy: precision equipment is used to ensure consistent cutting dimensions to meet strict industrial standards.

- High-quality edge treatment: no burrs, no cracks, improves subsequent processing efficiency and reduces production losses.

- Strong processing compatibility: suitable for stamping, bending, welding, coating and other processes, widely used in industrial manufacturing.

- High strength and corrosion resistance: 6061 aluminum alloy has excellent mechanical properties and corrosion resistance, and is suitable for automobile, aviation, electronics and other fields.

- Stable supply and customized services: Different specifications can be provided according to customer needs to ensure production efficiency and consistency.

6061 aluminum strip product application

- Electronic equipment heat sinks (computer, mobile phone heat sinks)

- LED lamp strips (lighting equipment, lamp structural parts)

- Car trims (window trims, dashboard trims)

- Transformer aluminum strip (conductive material for transformers in the power industry)

- Aerospace structural parts (aircraft skin, cabin components)

- Cable shielding aluminum tape (power cable, data line shielding layer)

6061 aluminum coil anodizing

Chalco uses advanced electrolytic dyeing, organic dyeing and other anodizing processes to form a dense oxide film on the surface of 6061 aluminum coil, which improves the corrosion resistance, hardness and aesthetics of the material, while enhancing its bonding with coatings or adhesives, making it suitable for various industrial and decorative applications.

6061 anodized aluminum coil product advantages

- A variety of colors are available: silver, black, gold, red, blue, bronze, champagne and other colors are available.

- Improve appearance: Can form matte, glossy or multi-color coatings to improve decorative performance.

- Enhanced corrosion resistance: The oxide film effectively resists oxidation, acid and alkali corrosion, and extends the service life of aluminum.

- Improve surface hardness: The surface becomes harder after anodizing, and the wear resistance is greatly improved.

- Better coating adhesion: The oxide film enhances the adhesion of coatings or paints and is suitable for subsequent surface treatments.

- Environmentally friendly processing: no heavy metal residue, in line with environmental standards, suitable for high-demand industries.

Typical applications of 6061 anodized aluminum coil

- Electronic product casings (mobile phones, laptops, cameras)

- Aerospace (fuselage structure, cabin components)

- Auto parts (engine parts, decorative strips)

- Building curtain wall, decoration materials

- Precision instruments, medical equipment

6061 silver anodized

The most common anodizing color, no dyeing process, keep the original color of aluminum.

6061 black anodized

Obtained through electrolytic dyeing or organic dyeing, it has a high-end texture and strong weather resistance.

6061 bronze anodized

The color depth is adjustable, suitable for modern architectural decoration and home design.

6061 aluminum coil color coating

Chalco uses advanced color coating technology to coat the surface of 6061 aluminum coil with high-performance polyester (PE) or fluorocarbon (PVDF) coating, which makes it have excellent weather resistance, corrosion resistance and decorative effect. Color-coated aluminum coils not only have beautiful appearance, but also improve the durability of materials.

6061 color coated aluminum coil process advantages

- Excellent weather resistance: Fluorocarbon (PVDF) coating can resist UV rays, acid rain, and salt spray erosion, ensuring that the color remains stable for a long time and is not easy to fade.

- Excellent anti-corrosion performance: The coating can effectively protect aluminum from oxidation and environmental influences, extending its service life.

- A variety of color options: Available in silver, black, blue, red, champagne and other colors to meet different decoration needs.

- Excellent adhesion: The color coating is firmly bonded to the aluminum substrate and is not easy to peel off or crack. It is suitable for bending, stamping and other processing techniques.

- Environmentally friendly process: in compliance with RoHS, REACH and other environmental standards, safe and pollution-free.

Common applications of 6061 color coated aluminum coil

- Building curtain wall, roof system (color-coated aluminum veneer, aluminum honeycomb panel, ceiling)

- Household appliance casing (refrigerator, microwave oven, washing machine panel)

- Traffic facilities (highway signs, subway station decorative panels)

- Auto parts (decorative strips, body panels)

- Advertising industry (signs, display boards)

Silvery white 6061 color coated aluminum coil

Classic metallic feel, clean and simple visual, suitable for industrial and architectural fields.

Black 6061 color coated aluminum coil

It is high-end and has a strong visual impact, suitable for modern design style.

Red 6061 color coated aluminum coil

Eye-catching color, suitable for billboards, signs, and fire equipment.

6061 aluminum coil embossing

Chalco uses precision embossing technology to roll out regular relief patterns on the surface of 6061 aluminum coils to enhance the decorative, anti-skid and wear resistance of aluminum. 6061 aluminum alloy itself has excellent strength, corrosion resistance and machinability. After embossing, it is more suitable for architectural decoration, industrial anti-skid, mechanical equipment housing and other fields.

6061 embossed aluminum coil process advantages

- Strong anti-slip performance: Common patterns such as five ribs, diamonds, and orange peel can increase friction and are suitable for floors and pedals.

- Enhance decorative effect: Embossing treatment makes the surface of aluminum coil more three-dimensional, beautiful and durable, and is widely used in decorative panels.

- Wear-resistant and corrosion-resistant: 6061 aluminum alloy itself has excellent oxidation resistance. After embossing treatment, the surface is more wear-resistant and durable.

- Lightweight and high strength: Compared with other metal materials, 6061 embossed aluminum coil has high strength but light weight, which is easy to install and process.

- Customizable processing: We provide a variety of embossing styles such as five ribs, orange peel pattern, diamond, anti-slip pattern, etc., and can perform surface treatments such as coating and anodizing.

Common applications of 6061 embossed aluminum coil

- Industrial anti-slip floor (factory, workshop, step)

- Cold storage and air conditioning equipment housing (corrosion resistance, improved heat dissipation performance)

- Mechanical equipment housing (enhanced appearance, wear resistance)

- Transportation (trains, subways, car pedals)

- Building decoration materials (curtain wall, wall decoration)

6061 five- rib anti- slip aluminum coil

The most common, widely used in industrial anti-slip occasions

Diamond pattern 6061 pattern roll

Strong decorative effect, suitable for mechanical equipment, billboards

Orange peel 6061 pattern roll

Enhanced heat dissipation, suitable for cold storage and air conditioning equipment

6061 aluminum coil mirror polished

Chalco uses precision mirror polishing technology to achieve high brightness and mirror reflection effect on the surface of 6061 aluminum coils through mechanical polishing, chemical polishing or electrolytic polishing. 6061 aluminum alloy has excellent mechanical strength, corrosion resistance and machinability. After polishing, it can be widely used in high-end decoration, optical reflection, electronic products and other fields.

6061 mirror aluminum coil process advantages

- Ultra-high finish: After multiple polishing processes, the surface presents a high reflectivity close to that of a mirror, smooth and delicate.

- Enhance decorative effect: Mirror aluminum has a modern and premium feel, suitable for high-end decoration and home design.

- High reflectivity: The mirror surface can reflect light and improve light efficiency, and is suitable for lighting reflectors and solar reflectors.

- Strong corrosion resistance: 6061 aluminum alloy itself is corrosion-resistant, and after polishing, its anti-oxidation ability is further enhanced.

- Deep processing is possible: Mirror aluminum coils can be oxidized, coated, and colored to meet different needs.

Common applications of 6061 mirror aluminum coil

- LED lighting reflector (improve light utilization and enhance lighting effect)

- Solar reflectors (used in solar thermal systems to improve energy absorption efficiency)

- High-end decorative materials (hotels, shopping malls, luxury building interiors)

- Household appliance casings (high-end refrigerators, ovens, microwave oven casings)

- Automotive interior and decorative parts (instrument panels, decorative strips, rearview mirror bases)

- Consumer electronics products (notebook cases, mobile phone decorative panels)

Ordinary polished 6061 aluminum coil

Reflectivity 70% - 80%, used for general decoration, home appliance housings, and automotive decorative parts.

High gloss mirror polished 6061 aluminum coil

Reflectivity 85% - 90%, used for lighting reflectors, solar reflectors, and high-end decorations.

Ultra high reflective mirror polished 6061 aluminum coil

Reflectivity 90% - 95%, used for high-precision optical reflectors, laser reflectors, and photovoltaic equipment.

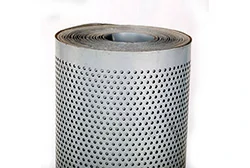

6061 aluminum coil punching

Using high-precision punching technology, holes of different shapes, sizes and spacings are customized on the surface of 6061 aluminum coils to meet the functional requirements of ventilation, noise reduction, decoration, etc. 6061 aluminum alloy itself has excellent strength, corrosion resistance and machinability. After punching, the material is lighter and has better air permeability and sound absorption.

6061 punching aluminum coil process advantages

- A variety of hole types are available: support customized designs such as round holes, square holes, long holes, hexagonal holes, diamond holes, and special-shaped holes.

- Lightweight design: After punching, the aluminum material is lighter, which reduces the installation load and improves material utilization.

- Enhanced ventilation and light transmittance: Suitable for scenes that require air circulation and light transmittance, such as curtain walls and ventilation panels.

- Good sound absorption and noise reduction performance: The punching structure can absorb sound waves and reduce noise, suitable for noise barriers.

- High corrosion resistance: 6061 aluminum alloy has natural oxidation resistance and can be further anodized or coated to improve weather resistance.

Common applications of 6061 punching aluminum coil

- Noise reduction barriers (highway, subway, factory noise reduction walls)

- Ventilation system panels (air conditioning, ventilation equipment)

- Building curtain walls and decoration (light-transmitting curtain walls, metal screens, decorative panels)

- Filtration equipment (industrial filters, air purification equipment)

- Mechanical protection cover (equipment protection plate, heat dissipation hole)

- Metal mesh guardrails (stair railings, fences, safety nets)

Round punching

Diameter 1mm – 10mm, evenly distributed or custom arrangement available.

Square hole/ long punching

Suitable for ventilation, drainage and filtration systems.

Hexagonal hole/diamond punching

It has strong decorative effect and is suitable for building curtain walls and design panels.

Chalco 6061 aluminum coil technical parameters

| Mechanical property of 6061 aluminum coil | ||||||

| Temper | Specified Thickness(in) | Tensile Strength - KSI | Elongation in 2 inches % | |||

| Ultimate | Yield | |||||

| Min | Max | Min | Max | |||

| O | 0.006 - 0.007 | - | twenty two | - | 12 | 10 |

| O | 0.008 - 0.009 | - | 22 | - | 12 | 12 |

| O | 0.010 - 0.020 | - | 22 | - | 12 | 14 |

| O | 0.021 - 0.128 | - | 22 | - | 12 | 16 |

| O | 0.129 - 0.250 | - | 22 | - | 12 | 18 |

| T4 | 0.006 - 0.007 | 30 | - | 16 | - | 10 |

| T4 | 0.008 - 0.009 | 30 | - | 16 | - | 12 |

| T4 | 0.010 - 0.020 | 30 | - | 16 | - | 14 |

| T4 | 0.021 - 0.249 | 30 | - | 16 | - | 16 |

| T42 | 0.006 - 0.007 | 30 | - | 14 | - | 10 |

| T42 | 0.008 - 0.009 | 30 | - | 14 | - | 12 |

| T42 | 0.010 - 0.020 | 30 | - | 14 | - | 14 |

| T42 | 0.021 - 0.250 | 30 | - | 14 | - | 16 |

| T6 and T62 | 0.006 - 0.007 | 42 | - | 35 | - | 4 |

| T6 and T62 | 0.008 - 0.009 | 42 | - | 35 | - | 6 |

| T6 and T62 | 0.010 - 0.020 | 42 | - | 35 | - | 8 |

| T6 and T62 | 0.021 - 0.250 | 42 | - | 35 | - | 10 |

| Chemical composition limits (%) of 6061 aluminum coil | ||

| Si | 0.4 - 0.8 | |

| Fe | 0.7 | |

| Cu | 0.15 - 0.4 | |

| Mn | 0.15 | |

| Mg | 0.8 - 1.2 | |

| Cr | 0.04 - 0.35 | |

| Ni | - | |

| Zn | 0.25 | |

| Ti | 0.15 | |

| Others | Each | 0.05 |

| Total | 0.15 | |

| Total | Aluminum Min | Remainder |

Chalco 6061 aluminum sheet coil strip product advantages

Chalco provides high-quality 6061 aluminum sheets, coils, and strips. These products have the characteristics of high strength, strong corrosion resistance, and excellent processing performance. They are widely used in aerospace, automobile manufacturing, architectural decoration, electronic equipment, machinery manufacturing and other industries.

- High-quality alloy material: Made of high-purity aluminum alloy, 6061-T6 / T4 / O and other states are optional, with high strength and good stability.

- Excellent corrosion resistance: It has excellent anti-oxidation and acid and alkali resistance, suitable for outdoor, marine and industrial environments.

- Excellent processing performance: good welding, cutting, stamping and bending performance, suitable for a variety of deep processing needs.

- High-precision dimensional control: Advanced production equipment and strict quality control ensure that thickness, width and tolerance meet international standards.

- A variety of surface treatments are available: anodizing, color coating, embossing, mirror polishing, punching and other processing technologies are available to meet different application requirements.

- Combination of light weight and high strength: Compared with steel, it is lighter but has excellent strength, making it an ideal material for automobiles, aviation, and rail transportation.

- Stable supply and customized services: Support customized width, thickness, and surface treatment to meet customers' personalized needs and ensure stable delivery.

Chalco 6061 aluminum sheet coil strip cooperation areas

Chalco 6061 aluminum sheet, aluminum coil, and aluminum strip are widely used in many industries due to their high strength, excellent corrosion resistance, good machinability, and welding performance. We cooperate with many companies around the world to provide high-quality aluminum materials to help the industry develop.

Aerospace

6061 aluminum is used for aircraft structural parts, skins, internal brackets, etc. It has the advantages of light weight, high strength and fatigue resistance. It complies with aviation standards such as AMS, ASTM, and MIL, and can meet the requirements of high-precision processing and durability.

Automotive

6061 aluminum coils are used in body frames, doors, engine covers, bumpers, etc. to improve lightweight and fuel economy. They are available in T4, T6, T651 and other states to meet different stamping, welding and surface treatment requirements.

Rail transit

6061 aluminum sheet/aluminum strip is suitable for high-speed rail, subway, light rail body, interior and exterior decoration, with the characteristics of impact resistance, corrosion resistance and long life. Support large-size aluminum coil customization to meet the special size requirements of rail transportation.

Architecture and decoration

Used for curtain walls, roofs, and decorative panels. It has the characteristics of high strength, good weather resistance, and various surface treatments (anodizing, color coating, etc. ) . It supports deep processing services such as punching, embossing, and mirror polishing to meet the needs of architectural design.

Electronics and new energy

6061 aluminum strip is widely used in LED reflectors, solar brackets, and battery housings. It has high thermal conductivity and stable mechanical properties. We provide high-precision aluminum strips suitable for transformers, heat sinks, 5G communication equipment and other fields.

Shipping and marine engineering

6061 aluminum has excellent seawater corrosion resistance and is suitable for applications such as hull structures, bulkheads, decks, and marine equipment. Aluminum certified by DNV, ABS, and LR classification societies can be provided to meet the requirements of marine environment use.

Mechanical manufacturing and industrial equipment

6061 aluminum is widely used in mechanical parts, molds, and equipment housings, with the advantages of high strength, weldability, and wear resistance. It is suitable for precision machining, CNC parts manufacturing, and industrial automation equipment.

6061 aluminum coil purchase guide

When purchasing 6061 aluminum coil, you may encounter problems with materials, status, specifications, suppliers, prices, etc. To help you make the most appropriate purchasing decision, Chalco has summarized the most common questions that customers are most concerned about, and combined with our product advantages, we have given professional answers.

1. What is the difference between 6061 aluminum coil and other aluminum coils?

6061 aluminum coil belongs to the Al-Mg-Si (aluminum magnesium silicon) alloy series, which is characterized by high strength, corrosion resistance, weldability, and anodization. It is suitable for structural parts, mechanical processing, aerospace, automobile manufacturing and other fields. The following is a comparison between 6061 and other common aluminum alloys:

| Alloy | Strength | Corrosion resistance | Weldability | Formability | Main Applications |

| 6061 Aluminum Coil | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ | Aerospace, automobile, construction, electronics, rail transportation |

| 5052 Aluminum Coil | ⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ | Marine engineering, ships, chemical equipment, traffic signs |

| 3003 Aluminum Coil | ⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐ | Roofs, food packaging, decorative panels, air conditioning equipment |

| 7075 Aluminum Coil | ⭐⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐ | ⭐⭐ | High-end aviation, military equipment, bicycle racks, precision parts |

| 1100 Aluminum Coil | ⭐ | ⭐⭐⭐⭐⭐ | ⭐ | ⭐⭐⭐⭐⭐ | Signs, home appliances, chemical storage, electronic screens |

If you need high-strength, weldable, corrosion-resistant aluminum coils that are suitable for a variety of processing, 6061 is the best choice. It is particularly suitable for high-end applications such as structural parts, aerospace, automotive manufacturing, and machining.

2. What are the common states of 6061 aluminum coils? How to choose?

| Temper | Hardness | Tensile strength (MPa) | Weldability | Formability | Typical Applications |

| 6061-O (annealed) | soft | 110-160 | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ | Suitable for bending and deep drawing, such as containers and tanks |

| 6061-T4 (natural aging) | medium | 205-270 | ⭐⭐⭐⭐ | ⭐⭐⭐ | Suitable for load-bearing parts such as car frames |

| 6061-T6 (fully aged ) | hard | 290-320 | ⭐⭐⭐ | ⭐⭐ | Applicable to structural parts, aviation components , mechanical parts |

| 6061-T651 (stress relief) | hard | 290-320 | ⭐⭐⭐ | ⭐⭐ | Suitable for high-precision machining, such as molds and precision equipment |

- If you need a bendable and easy-to-process material, choose O state (annealed state).

- If both strength and processability are required, T4 state is more suitable.

- For maximum strength, choose T6 or T651 (stress relieved, suitable for precision machining).

- Chalco can provide 6061 Aluminum Coil in all conditions and recommend the best solution for your needs!

3. How to choose the right 6061 aluminum coil supplier? What are the advantages of Chalco?

Choosing an aluminum coil supplier requires considering quality, specifications, supply stability, and technical support. Chalco is your ideal partner with leading production capabilities and strict quality control.

- Production Capacity and Quality: Chalco is certified by ISO 9001, ASTM, EN, etc. and uses advanced production technology to ensure stable product quality.

- Complete specifications and support customization: providing 0.2mm - 6mm thickness, 100mm - 2000mm width, supporting multiple states and surface treatments to meet different needs.

- Stable supply and fast delivery: multiple production lines, large-scale inventory, support for large-volume orders, fast delivery, and ensure a stable supply chain.

- Technical support and after-sales: Professional teams provide material selection suggestions, processing guidance and after-sales support to help customers optimize applications and improve efficiency.

4. What is the price of 6061 aluminum coil? What factors affect the price?

6061 Aluminum coil prices fluctuate due to a variety of factors, including:

- Alloy composition: 6061 contains magnesium and silicon. The price will vary depending on the proportion of the alloy composition.

- Thickness and Width: Thicker and wider aluminum coils are more expensive because they are more difficult to process.

- Tempers (T6, T4, O): T6 is fully heat treated and has a higher cost.

- Surface treatment: Special processes such as anodizing, color coating, mirror polishing, etc. will increase costs.

- Market conditions: Aluminum ingot price, raw material cost, and transportation costs affect the final price.

Chalco price advantage:

- We produce and sell our own products, reducing intermediate costs and making prices more competitive.

- Stable supply, not affected by short-term market fluctuations, long-term cooperative customers can enjoy preferential price policies.

- Bulk orders are more favorable, welcome to consult for real-time prices and discount information!

5. What further processing can be done on 6061 aluminum coil? What processing services does Chalco provide?

6061 aluminum coil can be processed in various ways according to different application requirements:

- Slitting and longitudinal cutting (customized aluminum strips of different widths)

- Anodizing (improves corrosion resistance, suitable for decoration, electronic housing)

- Color coating (strong weather resistance, suitable for building curtain walls and billboards)

- Mirror polish (high reflectivity, suitable for lighting, solar energy applications)

- Punching (noise reduction, ventilation, suitable for noise barriers, filters)

- Embossing (anti-slip, beautiful, suitable for anti-slip floors, decorative panels)

Chalco can provide one-stop 6061 aluminum coil processing services, reducing your procurement process and improving production efficiency!

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote