If you're looking for a lightweight yet strong, corrosion-resistant, and highly customizable aluminum profile for building display racks, decorative frames, or structural supports, our aluminum C channel and slide track channel are the perfect choice!

Aluminum C channel specifications

Standards: ASTM B308, AMS-QQ-A-200/8, ASTM B221, EN 755, EN 573, ISO 6362

Certifications: ISO 9001, ISO 14001, RoHS, REACH, CE, AS9100

Anodized finish compliant with MIL-A-8625F standard

We provide a full factory quality inspection report, covering key performance tests like tensile strength, yield strength, and chemical composition analysis. Every batch is strictly tested to meet ASTM and GB standards!

Common aluminum C channel alloys

-

6063 Aluminum C Channel

6063 Aluminum C ChannelIdeal for construction, decoration, doors and windows, and furniture. It's the most widely used commercial alloy.

Excellent extrudability smooth surface finish high corrosion resistance low cost -

6061 Aluminum C Channel

6061 Aluminum C ChannelCommonly used in industrial structures, scaffolding, marine applications, and furniture. Offers strength close to structural steel, making it perfect for load-bearing projects.

High strength outstanding corrosion resistance good weldability -

7075 Aluminum C Channel

7075 Aluminum C ChannelMainly used in aerospace, high-performance machinery, and racing vehicles. Suitable for advanced manufacturing needs.

Ultra-high strength corrosion resistant excellent crack resistance

Popular aluminum C channel products

We offer free samples so you can test the aluminum profiles before placing an order—ensuring the quality meets your expectations. Quick Quote

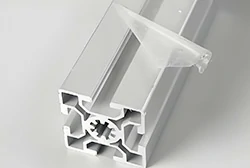

Extruded Aluminum C Channel

Made from high-quality aluminum alloy through precision extrusion. Lightweight yet strong—perfect for construction and industrial framing.

Contact us now

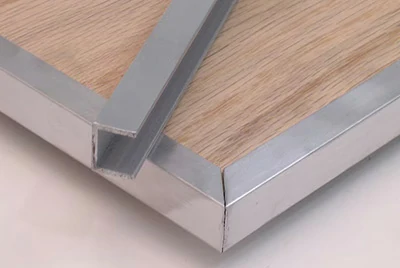

Aluminum C Slide Track Channel

Smooth surface and wear-resistant. Specially designed for sliding doors, drawer tracks, and moving components.

Contact us nowAluminium C Beam

Built for higher load-bearing capacity. Strong and stable—ideal for industrial equipment, heavy-duty brackets, and mechanical engineering.

Contact us now

Aluminum C Channel With Holes

Pre-drilled for fast and easy installation. Great for modular structures, racks, and industrial systems that require quick assembly.engineering.

Contact us nowAnodized Aluminum C Channel

Attractive and durable surface with excellent corrosion resistance. Perfect for premium décor and long-term outdoor use.

Contact us now

White Aluminum C Channel

Coated with a clean white finish. Sleek and modern—ideal for interior decoration, furniture frames, and architectural detailing.

Contact us nowSmall Aluminum C Channel

Compact and lightweight. Perfect for furniture accessories, display frames, decorative edges, and precision devices.

Contact us now

Aluminum C channel sizes

- Available standard stock lengths: 2 ft, 4 ft, 6 ft, 8 ft, 12 ft, and 25 ft (custom cut lengths available upon request)

- Length tolerance: ±1/16 inch

- Surface finish: Mill finish by default. Anodizing, powder coating, and sandblasting are available on request.

- Processing & customization: Die extrusion, precision cutting, and CNC machining.

Whether you need standard sizes or custom lengths, our American standard aluminum channel sizes are designed to meet your exact project needs. Contact us anytime—we're here to help! Quick Quote

Popular aluminum C channel sizes:

-

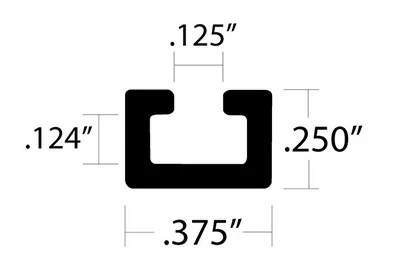

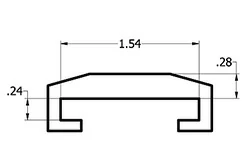

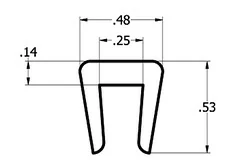

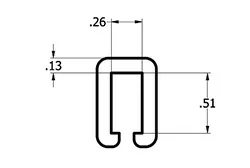

Aluminum C Channel – Slide Track – .375″ X .250″ (3/8″ x 1/4″)Inquire Now

Aluminum C Channel – Slide Track – .375″ X .250″ (3/8″ x 1/4″)Inquire NowSurface finish: Clear satin anodized, black anodized, or mill finish (custom finishes available) -

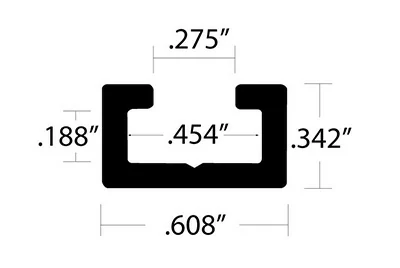

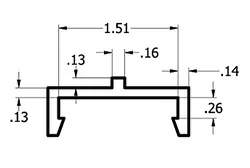

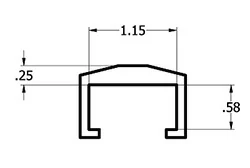

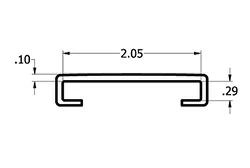

Aluminum C Channel – Sliding Window Track – .608″ X .342″ (19/32″ x 11/32″)Inquire Now

Aluminum C Channel – Sliding Window Track – .608″ X .342″ (19/32″ x 11/32″)Inquire NowStocked in 8′ lengths (96 inches) -

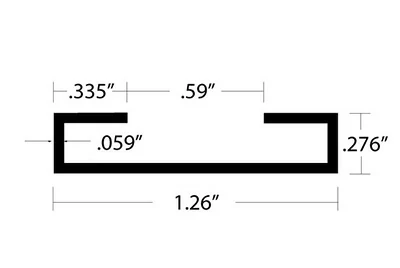

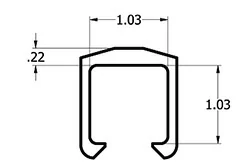

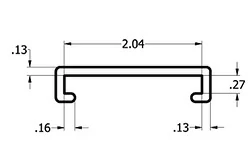

Aluminum C-Shaped Channel – Slide Track – 1.26″ x .276″ x .059″ (1-1/4″ x 9/32″ x 1/16″)Inquire Now

Aluminum C-Shaped Channel – Slide Track – 1.26″ x .276″ x .059″ (1-1/4″ x 9/32″ x 1/16″)Inquire NowStocked in 12′ lengths (144 inches) -

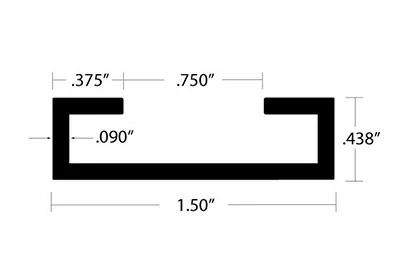

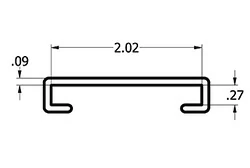

This sliding window channel is stocked in 12′ lengths ( 144 inches )Inquire Now

This sliding window channel is stocked in 12′ lengths ( 144 inches )Inquire NowStocked in 12′ lengths (144 inches) -

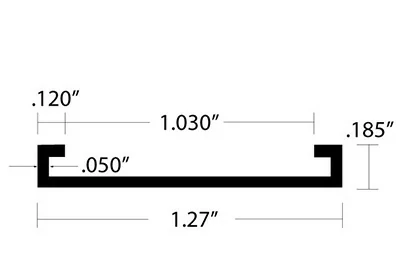

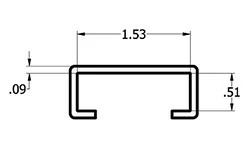

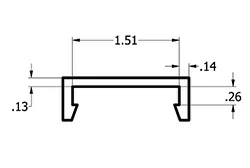

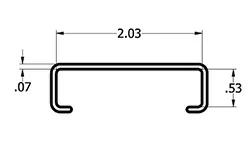

Aluminum C Channel – Single Track Sliding Channel – 1.270″ x .185″ x .050 (1-9/32″ x 3/16″ x 1/16″)Inquire Now

Aluminum C Channel – Single Track Sliding Channel – 1.270″ x .185″ x .050 (1-9/32″ x 3/16″ x 1/16″)Inquire NowThis sliding door bottom rail is stocked in 12′ lengths (144 inches)

1/4'' x 1 1/2'' C Channel

3/16'' x 1-1/2'' C Channel

9/16'' x 1-1/8'' C Channel

1'' x 1'' C Channel

1/2'' x 1 1/2'' C Channel

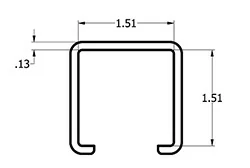

1 1/2'' x 1 1/2'' C Channel

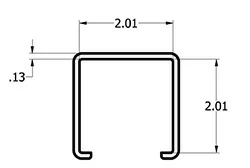

2'' x 2'' C Channel

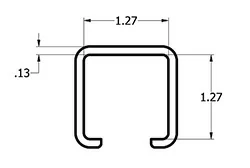

1 1/4'' x 1 1/4'' C Channel

1/4'' x 1-1/2'' C Channel

1/4'' x 2'' C Channel

1/4'' x 2'' C Channel

1/2'' x 2'' C Channel

1/2'' x 1/4'' C Channel

1/2'' x 1/4'' C Channel

1/4'' x 2'' C Channel

Aluminum C channel size stock list:

| Product (inches) | Product (mm) | Stock status | Supports custom die extrusion |

| 1/4" Aluminum C Channel | 6.35 mm | Regular stock | Yes |

| 3/8" Aluminum C Channel | 9.525 mm | Regular stock | Yes |

| 1/2" Aluminum C Channel | 12.7 mm | Regular stock | Yes |

| 3/4" Aluminum C Channel | 19.05 mm | Regular stock | Yes |

| 1" Aluminum C Channel | 25.4 mm | Regular stock | Yes |

| 1 1/2" (1.5") Aluminum C Channel | 38.1 mm | Regular stock | Yes |

| 2" Aluminum C Channel | 50.8 mm | Regular stock | Yes |

| 3" Aluminum C Channel | 76.2 mm | Regular stock | Yes |

| 4" Aluminum C Channel | 101.6 mm | Regular stock | Yes |

| 6" Aluminum C Channel | 152.4 mm | Small amount of stock | Yes |

| 8" Aluminum C Channel | 203.2 mm | Small amount of stock | Yes |

Aluminum C channel surface finishes

We offer a wide range of surface finishes for our aluminum C channel, allowing you to choose the most suitable option for your project needs:

- Mill finish: Smooth, natural aluminum surface. Cost-effective and ready for secondary processing.

- Clear anodized: Long-lasting shine with excellent corrosion resistance.

- Anodizing: Decorative, wear-resistant, and corrosion-resistant—perfect for modern architectural designs.

- Powder coating: Vibrant colors with strong durability. Ideal for long-term outdoor use.

- Brushed finish: Silky surface texture enhances visual appeal and adds a modern touch.

- Satin anodized: Matte and refined appearance with a soft touch. Elevates product quality.

- Wood grain sublimation: Realistic wood texture, eco-friendly, and durable—perfect for premium decorative applications.

Available in clear satin

Available in clear satin

Black

Gold

Silver

Wine red

Satin anodized aluminum J channel

Satin anodized aluminum J channel

White Aluminum J-Channel

In addition to these standard colors and finishes, we also offer a wide range of custom colors to match your unique design needs. Contact us to request the full aluminum C channel color chart. Quick Quote

Applications of aluminum C channel

Exhibition and display systems

Lightweight and easy to assemble. Ideal for exhibition booths, display racks, and portable furniture—perfect for quick setup and mobility.

Contact us now

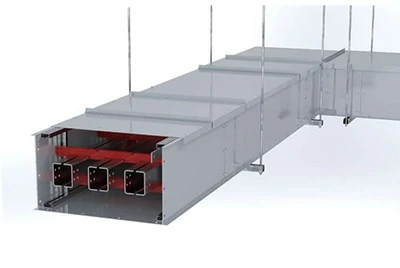

Electrical systems and heat sinks

Commonly used in busbar systems and heat sinks. Supports efficient heat dissipation and can be easily anodized for added performance.

Contact us nowIndustrial and manufacturing equipment

Widely used for workbenches, inspection tables, carts, and structural frames. Its strength and low weight make it a favorite in industrial applications.

Contact us now

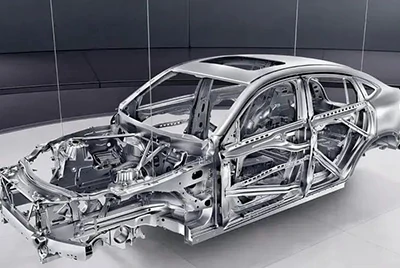

Transportation industry

Used in vehicle, bus, and marine framing structures. Corrosion resistance and lightweight design improve fuel efficiency and durability.

Contact us now

Features of aluminum C channel

- Excellent strength and high load-bearing capacity, designed for both construction and industrial structures.

- Superior weather resistance and corrosion protection, ideal for long-term outdoor use. Resists UV rays, salt spray, and rust.

- Precise machinability and customization. Supports CNC machining, drilling, welding, and cutting for highly tailored specifications.

- Lightweight design makes it easy to install, transport, and maintain.

- Maintains structural strength even in extremely cold conditions—no brittleness like other metals.

- Non-sparking and non-flammable, making it safe for use in highly flammable or explosive industrial environments.

- 100% recyclable, helping customers reduce environmental impact and achieve sustainability goals.

Aluminum C channel fabrication services

In addition to standard, custom, and OEM extrusions, as well as anodizing and powder coating, Chalco Aluminum also offers full light-metal fabrication and assembly services for your aluminum C channel needs, including:

- Drilling/Countersinking

- Welding

- Cutting to length, Mitering

- Forming/Bending

- Punching

- Deburring

- Assembly

- Brushing/Straight lining

Aluminum C channel price advantages

Bulk discounts and custom pricing

We offer flexible bulk purchase discounts for large-volume orders and long-term partnership clients.

Low MOQ for flexible purchasing

We support small-batch orders to meet the needs of different project stages—helping you reduce trial-and-error costs.

Free sample, risk-free testing

To ensure the product meets your expectations, we provide free aluminum C channel samples for testing.

Fast and free quotation service

Just let us know your required size, length, alloy type, and surface finish. Our expert team will quickly send you a clear and detailed quote—making it easy to plan your budget. Quick Quote

Related aluminum C channel products

aluminum U channel extrusions

aluminium T profile

aluminum I beam

aluminium H section

F channel aluminum extrusion

Hat channel aluminum

Aluminum C channel packaging and shipping

- Rush orders: Chalco Aluminum offers expedited shipping for most in-stock, non-oversized orders.

- Cardboard tube: Ideal for small-sized or single-piece materials. Prevents scratches and damage during transit.

- Boxes: Suitable for medium-sized orders. Provides extra protection.

- Pallet: Best for large or bulk orders. Secure and stable, easy for loading and unloading.

- Custom packaging: Have special packing needs? We can package your order to your exact specifications.

Protective film

Kraft paper

Wooden crate

Pallet

Full container load (FCL)

Less than container load (LCL)

Frequently asked questions about aluminum C channel

What is aluminum C channel used for?

Aluminum C channel is widely used in building structures, door and window frames, indoor and outdoor décor, furniture manufacturing, industrial equipment framing, electrical systems, and irrigation pipelines.

How strong is aluminum C channel?

Aluminum C channel offers excellent strength-to-weight ratio. It reliably supports structural and industrial loads with stable performance.

Can aluminum C channel resist twisting?

Yes. Its C-shaped cross-section enhances torsional stiffness, helping prevent twisting and deformation in structural applications.

Can aluminum C channel be bent?

Absolutely. It has great workability and can be bent, cut, drilled, welded, or CNC-machined to meet various custom requirements.

How do you cut aluminum C channel?

Use specialized aluminum saw blades or high-speed metal cutting tools for clean, precise cuts. Applying cutting lubricant is recommended to reduce heat and prevent burrs.