1050 is one of the most popular alloys in aluminum slugs, widely used in industries such as cosmetics, pharmaceuticals, electronics, and automotive.

It offers excellent corrosion resistance and formability, with an elongation rate of 25%, making it highly suitable for deep drawing and forming. It also has a moderate hardness (Brinell hardness 23HB), and its outstanding comprehensive properties make it indispensable in industrial applications, especially in the cosmetics and pharmaceutical packaging sectors.

-

1050 punched aluminum slug

Temper: O

DIA: 0.4”-8”(10-200mm)

Spec: EN 570, EN 573

-

1050 sawing aluminum slug

Temper: O, H112

DIA: 0.12”-54.2”(3-130mm)

Spec: EN 755, EN 754

Popular products made with 1050 aluminum slugs

1050 Aluminum Slugs for Collapsible Tubes

Primarily used for manufacturing various types of ointment tubes, pet food tubes, shoe polish tubes, and toothpaste tubes.

1050 Aluminum Slugs for Eletronic Capacitor Shell

Primarily used in the production of various capacitor housings through cold extrusion.

1050 Aluminum Slugs for Aerosol Bottle

Widely used in the fields of personal care, detergents, and insecticides.

1050 Aluminium Slug for Beverage/Food Container

Mainly used in the production of various tea cans, beer bottles, and other food and beverage containers.

1050 Aluminum slugs for Cosmetic Packaging

Commonly used for manufacturing lipstick tubes, mascara tubes, and face cream jars.

1050 Aluminum Slug for Pharmaceutical Packaging

Primarily used for manufacturing various medicine bottles, caps, and ointment tubes.

1050 Aluminum Slugs for Packaging Closure

Widely used for producing various types of bottle caps, screw caps, and flip-top caps.

1050 Aluminum Slug for Automotive Parts

Mainly used for producing various fuel filter housings, airbag system components, and reverse radar housings.

1050 Aluminum Slugs for Cigarette Lighter Shell

Mainly used for producing various types of cigarette lighters, cigar lighters, and spark igniter casings.

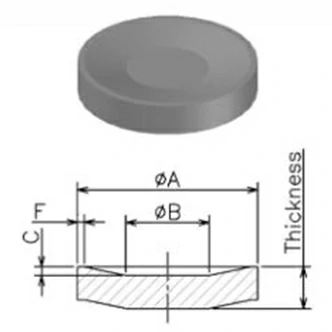

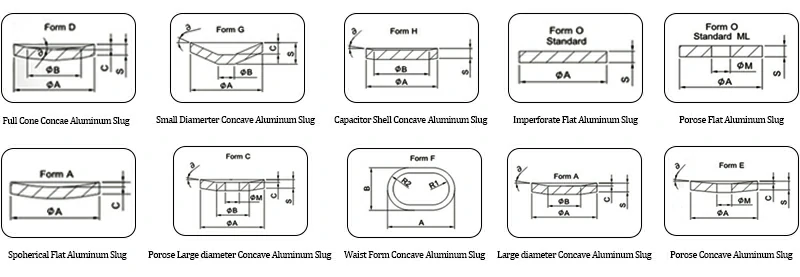

Diverse shapes of 1050 aluminum slugs

Surface shape of aluminum slugs

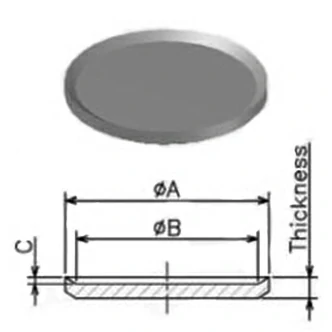

Aluminum slugs can be categorized based on their surface shape into Flat Shape, Domed Flat Shape, and Concave Shape.

Shape of aluminum slugs

Aluminum slugs come in various shapes, including Round, Oval, Square, and Rectangle.

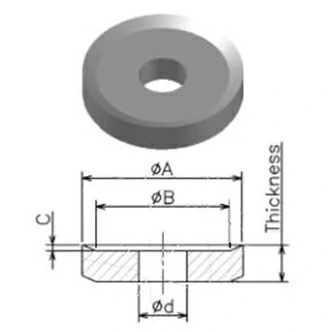

Aluminum slugs with or without holes

Aluminum slugs can also be classified based on whether they have holes, into Flat with Hole and Concave with Hole.

Processing services we offer

During the production process, we offer a variety of block processing services based on customer requirements, including:

- Tumbling

- Vibratory

- Shot blasting

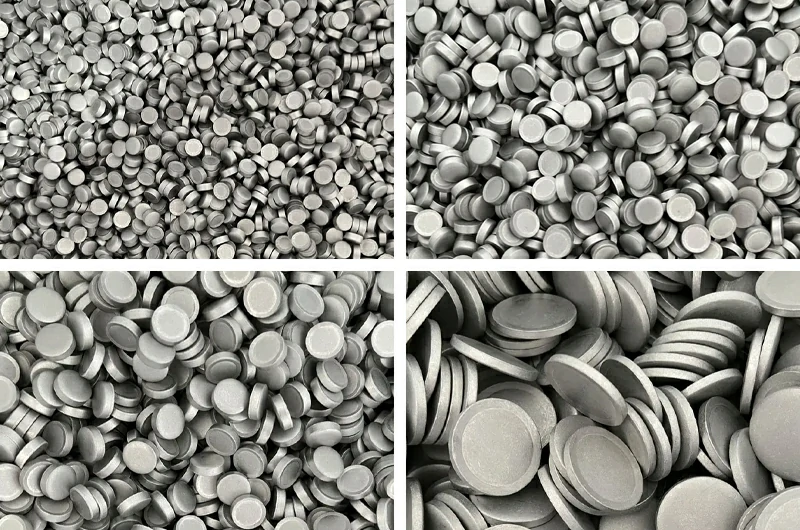

Gallery of aluminum slug

Characteristics of 1050 aluminum slug

- High Corrosion Resistance: 1050 aluminum slugs exhibit excellent corrosion resistance, making them ideal for packaging applications in humid or chemically active environments.

- Good Formability: Aluminum slugs can be molded into various shapes without compromising strength, helping manufacturers achieve complex designs.

- Reduced Defect Rate: Thanks to high purity and precision processing, 1050 aluminum slugs significantly reduce product defect rates, ensuring stable quality.

- Reduced Tool Wear: The properties of 1050 aluminum slugs help reduce wear on equipment and tools during extrusion and impact extrusion, extending their lifespan.

- Improved Coating Quality: Using fewer lubricants improves the application quality of primers and interior coatings, ensuring that the final products are more visually appealing.

Applications of 1050 aluminum slug

- Cosmetic Packaging: Lipstick tubes, foundation cases, perfume bottles, etc.

- Electronics: Capacitor shells, requiring reliable conductivity and corrosion resistance.

- Aerosol Cans: Used for pharmaceuticals, air fresheners, etc.

- Automotive Parts: Lightweight parts designed to improve vehicle efficiency.

- Food Packaging: Ensures high levels of safety and product integrity.

Related products of EN AW-1050A aluminum slug

Product guide of 1050 aluminum slug

Standard Specifications of 1050 aluminum slug

- EN 573-3: 2009 Aluminium and aluminium alloys. Chemical composition and form of wrought products. Chemical composition and form of products

- EN 570: 2007 Aluminium and aluminium alloys. Impact extrusion slugs obtained from wrought products. Specification

- EN 754-2: 2008 Aluminium and aluminium alloys. Cold drawn rod/bar and tube. Mechanical properties

- EN 755-2: 2008 Aluminium and aluminium alloys. Extruded rod/bar, tube and profiles. Mechanical properties

Equivalent grades of grade 1050 aluminum

| EU EN | USA | Germany DIN, WNr | Japan JIS | France AFNOR | England BS | Russia GOST | Inter ISO |

| ENAW-Al99.5 | A91050 | 3.0255 Al99.5 | 1050 | 1050A | 1050A | AD0 | Al99.5 |

Chemical composition of 1050A aluminum slug (EN 573-2)

| Element | EN-AW 1050A |

| Si | 0.25 |

| Fe | 0.40 |

| Cu | 0.05 |

| Mn | 0.05 |

| Mg | 0.05 |

| Cr | - |

| Ni | - |

| Zn | 0.07 |

| Ti | 0.05 |

| Remarks | - |

| Others (Each) | 0.03 |

| Others (Total) | - |

| Al | 99.5 |

Physical properties of 1050 aluminum slug

| Properties | Value |

| Density | 2.71 g/cm³ |

| Melting point | 650°C |

| Thermal Expansion | 24 x 10-6 /K |

| Modulus of Elasticity | 71 GPa |

| Thermal Conductivity | 222W/m.K |

| Electrical Resistivity | 0.0282 x 10-6 Ω .m |

Mechanical properties of 1050 aluminum slug

| Properties | Value |

| Proof Strength | 20MPa |

| Tensile Strength | 60-95MPa |

| Elongation | 23-25% |

| Hardness Vickers | 23HV |

Guide to purchasing aluminum slug

1. Alloy selection

The alloy type of Aluminum Slug determines its performance and application range. We offer a variety of alloy grades, including 1050, 1060, 1070, 3003, 6060, and more, suitable for different requirements such as mechanical strength, corrosion resistance, and formability.

For example, 1050 and 1070 alloys are ideal for food packaging, 3003 is commonly used for automotive parts, and 6061 is suitable for high-strength structural applications. Customers should choose the appropriate alloy based on the final application to ensure optimal product performance.

2. Shape selection

From the shape, the aluminum slugs can be separated as flat round, semicircular, conical, square, rectangular, oval, perforated, and non-porous type.

- Non-porous flat round, semi-circular, conical types are suitable for processing canned products.

- Flat round, perforated semi-circular, conical types are suitable for processing tube products.

- The square, oval, and rectangular types are suitable for processing parts.

| Shape | ||

|

|

|

3.Dimensions and tolerances (EN 570)

The dimensions and tolerances of Aluminum Slug are vital for subsequent processing and forming. We provide various production methods and specifications for aluminum slugs, including different thicknesses and diameters, and can offer high-precision tolerance control based on customer requirements. This ensures the product is suitable for high-standard processing. Below are the tolerance tables for different shapes and production methods:

Circular Aluminum Slugs: Diameter tolerance

| Tolerances on diameter of punched aluminum slugs | |

| Aluminum Slug Diameter/mm | Tolerances/mm |

| ≤10 | ±0.02 |

| 10-40 | ±0.03 |

| 40-60 | ±0.04 |

| 60-80 | ±0.05 |

| 80-120 | ±0.06 |

| 120-150 | ±0.08 |

| 150-200 | ±0.10 |

| Tolerances on diameter of sawn aluminum slugs | |

| Aluminum Slug Diameter/mm | Tolerances/mm |

| 3-6 | 0 - 0.07 |

| 6-10 | 0 - 0.09 |

| 10-18 | 0 - 0.11 |

| 18-30 | 0 - 0.13 |

| 30-50 | 0 - 0.16 |

| 50-65 | 0 - 0.5 |

| 65-80 | 0 - 0.6 |

| 80-130 | 0 - 0.9 |

Aluminum Slugs with Holes: Hole diameter tolerance

| Hole diameter of punched aluminum slugs | |

| Aluminum Slug Diameter/mm | Tolerances/mm |

| ≤10 | ±0.05 |

| 10-20 | ±0.07 |

| ≥20 | ±0.1 |

*The above tolerances apply to stamped aluminum slugs with holes that do not exceed 40% of the slug diameter and with thickness no more than two-thirds of the hole diameter. Eccentricity of the hole must not exceed 0.15mm.

| Tolerances on outside or inside diameter and wall thickness for sawn slugs | ||||||||

| Outside diameter or inside diameter/mm | Tolerances for wall thicknesses/mm | |||||||

| Size | Tolerances | 2.5-3 | 3-5 | 5-8 | 8-10 | 10-15 | 15-20 | 20-25 |

| 15-20 | ±0.25 | ±0.25 | - | - | - | - | - | - |

| 20-30 | ±0.30 | ±0.25 | ±0.30 | - | - | - | - | - |

| 30-50 | ±0.30 | ±0.30 | ±0.35 | ±0.40 | ±0.45 | - | - | - |

| 50-100 | ±0.50 | - | ±0.35 | ±0.45 | ±0.50 | ±0.55 | ±0.60 | - |

| 100-130 | ±0.70 | - | - | ±0.45 | ±0.50 | ±0.60 | ±0.60 | ±0.60 |

*The above tolerances apply to hole saw cut blocks made from round tube with or without extrusion seam.

Rectangular Aluminum Slugs: Length and width tolerance

| Tolerances on length and width of punched rectangular slugs | |

| Length and width/mm | Tolerances/mm |

| ≤10 | ±0.05 |

| 10-20 | ±0.08 |

| 20-40 | ±0.10 |

| 40-60 | ±0.12 |

| 60-120 | ±0.14 |

| 120-150 | ±0.17 |

| 150-200 | ±0.20 |

Rectangular Aluminum Slugs: Thickness tolerance

| Tolerances on thickness of punched slugs | |

| Slugs thicknesses/mm | Tolerances/mm |

| ≤2.8 | ±0.03 |

| 2.8-6.5 | ±0.05 |

| 6.5-8.5 | ±0.07 |

| 8.5-10.5 | ±0.10 |

| 10.5-15 | ±0.14 |

| 15-20 | ±0.18 |

| 20-25 | ±0.22 |

| 25-30 | ±0.26 |

| 30-40 | ±0.30 |

*The tolerances apply only to slugs with a maximum thickness not exceeding half the diameter (in the case of round slugs) or not exceeding half the width (in the case of rectangular slugs).

Saw-cut Aluminum Slugs: Parallelism and verticality tolerance

| Tolerances on thickness of sawn slugs | ||||

| Diameter or width | Tolerances for thicknesses/mm | |||

| 7 - 10 | 10 - 20 | 20 - 40 | 40 - 70 | |

| ≤15 | ±0.15 | ±0.15 | ±0.15 | ±0.20 |

| 15-30 | ±0.15 | ±0.20 | ±0.20 | ±0.25 |

| 30-70 | ±0.15 | ±0.20 | ±0.25 | ±0.30 |

| 70-100 | ±0.30 | ±0.35 | ±0.40 | ±0.45 |

| 100-130 | ±0.40 | ±0.45 | ±0.50 | ±0.60 |

4.Surface and edge quality

Slight scores, spallings or discolourations result from the manufacturing process. Scratches, scour

marks, indentations and other damage due to mechanical action cannot always be avoided.

An assessment of whether such defects are acceptable shall be based on the following:

- Large scores, spallings, cracks and damaged areas, incomplete slugs, flaking, formation of blisters and inclusions of foreign matter are not permitted. Slight damage due to production process, such as edge deformations, are unavoidable and hence is permitted.

- Slight scores, indentations and edge deformations, and discolourations due to a heat treatment or surface treatment, such as scouring or blasting, are unavoidable and hence are permitted.

5.Surface treatment

Surface treatment directly affects the appearance and performance of Aluminum Slug in processes like stamping and deep drawing. We offer a variety of surface treatments, primarily categorized into bright and roughened finishes.

After roughening, the aim is to improve the lubrication properties for better stamping efficiency. We provide coated, blasted, and tumbled surface treatments to meet the surface quality requirements of different industries.

The choice of surface treatment should take into account the final product's aesthetics, durability, and ease of subsequent processing.

6.Hardness requirements

| Chemical symbols | Brinell hardness HB | Chemical symbols | Brinell hardness HB |

| EN AW.1098 | 18 | ENAW-5005A | 37 |

| EN AW-1080A | 19 | EN AW-5305 | 33 |

| EN AW-1070A" | 21 | EN AW-5505 | 33 |

| EN AW-1050A" | 23 | EN AW-5110 | 27 |

| EN AW-1200 | 25 | EN AW-5210 | 27 |

| EN AW-2011 | 50 | ENAW-5754 | 58 |

| EN AW-3102 | 23 | EN AW-6060 | 35 |

| EN AW-3103 | 33 | EN AW-6061 | 40 |

| EN AW-3207 | 25 | EN AW-6082 | 40 |

7.Packaging

To ensure the integrity and quality of Aluminum Slug during transportation and storage, we offer professional packaging services. Each packaging unit is carefully designed to prevent damage or contamination during transit.

- Packaging: Sturdy cardboard boxes are used for packaging, with each box holding 25kg.

- Pallets: Each pallet holds 45 boxes, with a total weight of 1125kg.

- Material: Wooden pallets, with dimensions of 1.1 x 1.1 x 1.1 meters.

FAQ

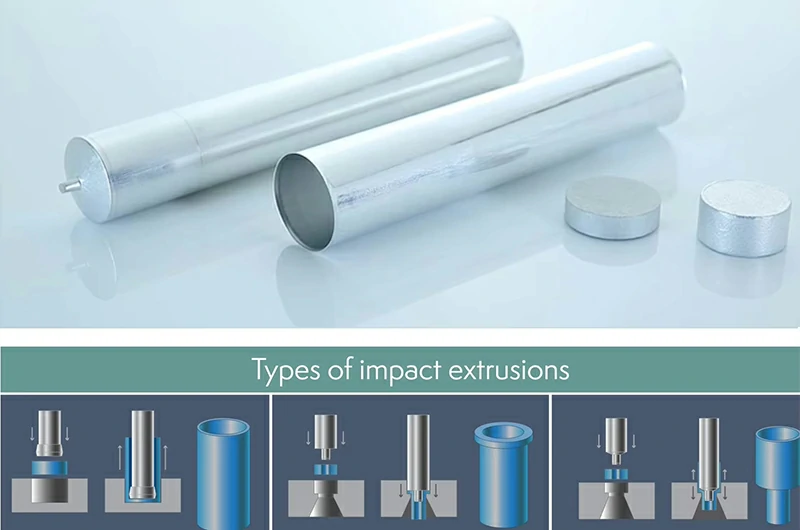

How is the aluminum electronic capacitor shell stamped?

1050 aluminum slugs are formed into electronic capacitor shells using a deep drawing process, which involves multiple stamping, trimming, and annealing steps.

The deep drawing process shapes the aluminum slugs into the desired shell, while the annealing treatment ensures good formability and mechanical properties.

Additionally, lubricants are used to reduce tool wear and ensure the products have smooth surface quality and consistent dimensions.

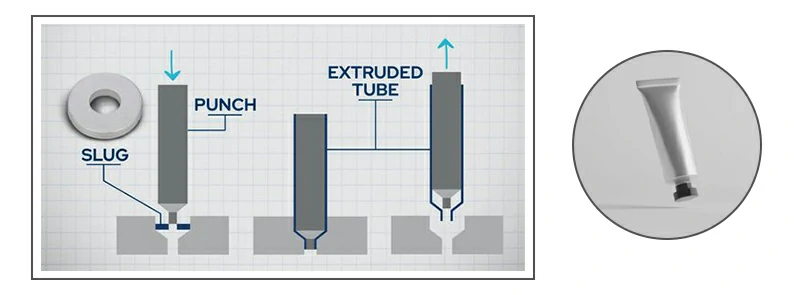

How is the aluminum collapsible tube stamped?

Aluminum Collapsible Tubes are typically manufactured using punched aluminum slugs through a combination of deep drawing and cold extrusion processes. In the production process, 1050 aluminum slugs are first subjected to precise stamping by a high-precision press, and then undergo multiple deep drawing operations to gradually extend the slug into a tube shape.

Lubricants are generally used during the stamping process to ensure smooth extrusion without tearing, followed by annealing treatment to enhance formability.

Can 1050 aluminum slug be used for stamping whole aluminum bottles?

Yes, due to the excellent machinability and deep drawing performance of 1050 aluminum slugs, they are well-suited for manufacturing whole aluminum bottles (such as cosmetic bottles, pharmaceutical bottles, and aerosol cans).

These aluminum bottles are typically formed through deep drawing and cold extrusion processes. The superior quality of the aluminum slugs ensures the final products are uniform and of high quality.