3003 aluminum slug is a disc or other shaped aluminum slug made of 3003 aluminum alloy. It has excellent corrosion resistance and medium strength, as well as good processing performance, and is suitable for a variety of stamping and forming processes.

Specification of 3003 aluminum slug

- EN 573-3

- EN 570

3003 aluminum slug product introduction

- Temper: O, H18

- Diameter: 5 – 140mm

- Thickness: 2.5 – 15mm

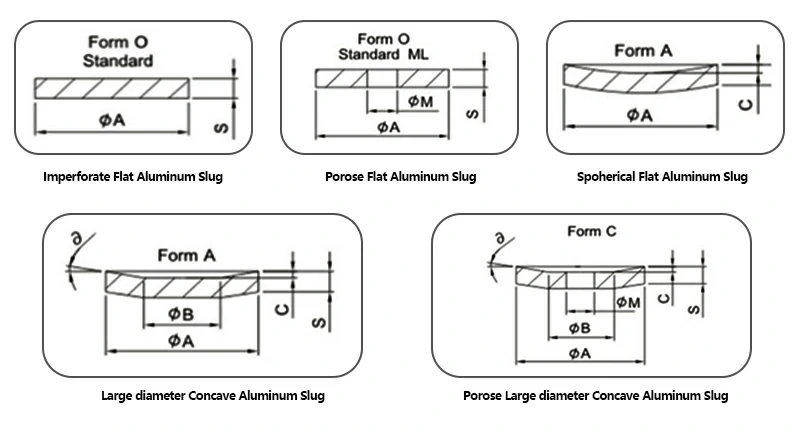

- Shape: Flat, Domed, Round, Oval, Rectangular, etc. Slugs with hole or without hole

3003 aluminum slug stock sizes

Below is a table of common sizes of 3003 aluminum slugs which are very popular among customers.

| Product | Diameter(mm) | Thickness(mm) | Diameter(inch) | Thickness(inch) |

| 3003 aluminum slug | 13.15mm | 2.8mm | 0.52" | 0.11" |

| 3003 aluminum slug | 13.15mm | 3.6mm | 0.52" | 0.14" |

| 3003 aluminum slug | 13.25mm | 3.1mm | 0.52" | 0.12" |

| 3003 aluminum slug | 13.25mm | 3.6mm | 0.52" | 0.14" |

| 3003 aluminum slug | 13.25mm | 4mm | 0.52" | 0.16" |

| 3003 aluminum slug | 14.7mm | 3.2mm | 0.58" | 0.13" |

| 3003 aluminum slug | 15.7mm | 5mm | 0.62" | 0.2" |

| 3003 aluminum slug | 15.65mm | 3.4mm | 0.62" | 0.13" |

| 3003 aluminum slug | 15.65mm | 3.6mm | 0.62" | 0.14" |

| 3003 aluminum slug | 15.65mm | 3.8mm | 0.62" | 0.15" |

| 3003 aluminum slug | 18.7mm | 3.5mm | 0.74" | 0.14" |

| 3003 aluminum slug | 18.7mm | 3.6mm | 0.74" | 0.14" |

| 3003 aluminum slug | 18.7mm | 3.8mm | 0.74" | 0.15" |

| 3003 aluminum slug | 20.4mm | 10mm | 0.8" | 0.39" |

| 3003 aluminum slug | 21.6mm | 8.5mm | 0.85" | 0.33" |

| 3003 aluminum slug | 21.7mm | 6mm | 0.85" | 0.24" |

| 3003 aluminum slug | 21.75mm | 4.2mm | 0.86" | 0.17" |

| 3003 aluminum slug | 22.75mm | 4mm | 0.9" | 0.16" |

| 3003 aluminum slug | 24.6mm | 3.3mm | 0.97" | 0.13" |

| 3003 aluminum slug | 24.6mm | 4mm | 0.97" | 0.16" |

| 3003 aluminum slug | 24.75mm | 4.3mm | 0.97" | 0.17" |

| 3003 aluminum slug | 24.75mm | 4.5mm | 0.97" | 0.18" |

| 3003 aluminum slug | 27.75mm | 4.2mm | 1.09" | 0.17" |

| 3003 aluminum slug | 27.75mm | 4.5mm | 1.09" | 0.18" |

| 3003 aluminum slug | 31mm | 3.5mm | 1.22" | 0.14" |

| 3003 aluminum slug | 31.6mm | 5.3mm | 1.24" | 0.21" |

| 3003 aluminum slug | 31.7mm | 3.8mm | 1.25" | 0.15" |

| 3003 aluminum slug | 32.4mm | 8mm | 1.28" | 0.31" |

| 3003 aluminum slug | 46.7mm | 7.9mm | 1.84" | 0.31" |

| 3003 aluminum slug | 46.7mm | 8.25mm | 1.84" | 0.32" |

| 3003 aluminum slug | 49.7mm | 4.6mm | 1.96" | 0.18" |

| 3003 aluminum slug | 49.7mm | 4.9mm | 1.96" | 0.19" |

| 3003 aluminum slug | 54.7mm | 5.4mm | 2.15" | 0.21" |

| 3003 aluminum slug | 62.7mm | 4.5mm | 2.47" | 0.18" |

| 3003 aluminum slug | 65.7mm | 6.5mm | 2.59" | 0.26" |

| 3003 aluminum slug | 72.7mm | 7.5mm | 2.86" | 0.3" |

| 3003 aluminum slug | 72.7mm | 9mm | 2.86" | 0.35" |

| 3003 aluminum slug | 87.7mm | 8.2mm | 3.45" | 0.32" |

| 3003 aluminum slug | 87.8mm | 9.1mm | 3.46" | 0.36" |

The above sizes are the sizes that customers often order, and they do not represent all sizes. If we do not have the size type you need, please contact us in time and we will give you a quick and professional solution.Quick Quote

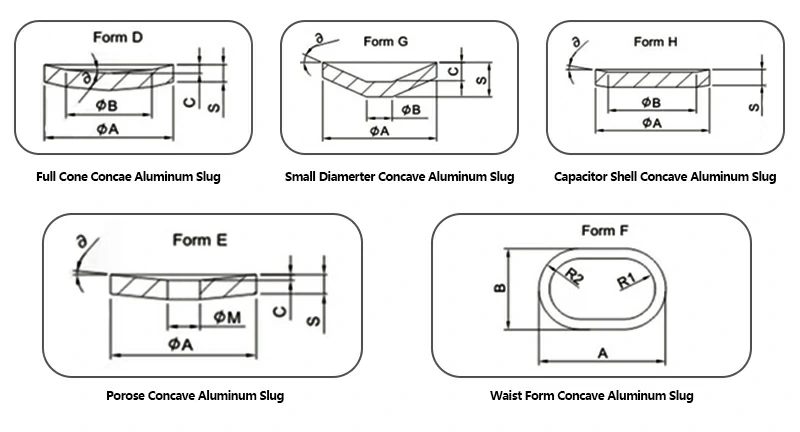

3003 aluminum slug popular type

Chalco can provide various types of 3003 aluminum slug to meet your different needs.

Round aluminum slug

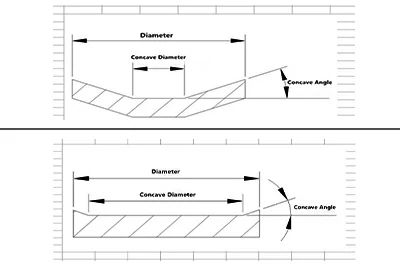

Concave aluminum slug

Oval aluminum slug

Round aluminum slug with hole

Square aluminum slug

Small cylindrical aluminum slug

Features of 3003 aluminum slug

Excellent corrosion resistance

3003 aluminum slug contains 1.0%-1.5% manganese, which has strong antioxidant ability and is suitable for humid or highly corrosive environments, such as food packaging, medicine and cosmetic containers.

Its corrosion resistance to the atmosphere, fresh water and certain chemicals is better than that of pure aluminum alloys (such as 1050 or 1060).

Good mechanical strength

Compared with 1000 series aluminum alloy, 3003 aluminum slug has higher strength and is suitable for products with certain requirements for mechanical properties.

It has moderate strength and is not easy to crack during the molding process, while meeting the durability requirements of the finished product.

Excellent processing performance

It has good ductility and plasticity, is suitable for various processes such as stamping and deep drawing, and can be processed into complex shapes.

Easy to cut and weld, and has high flexibility in subsequent processing.

Moderate cost

Compared with high-strength aluminum alloys (such as 5000 series or 7000 series), 3003 aluminum slug has a lower production cost and high cost performance, and is widely used in occasions that require both durability and economy.

Environmentally friendly recyclability

3003 aluminum slug can be recycled multiple times, which meets the requirements of environmental protection and sustainable development.

Application of 3003 aluminum slug

Can industry

3003 aluminum slug is the main material for the production of aluminum aerosol cans, cosmetic cans and food cans. Through stamping, extrusion and stretching processes, 3003 aluminum slug can be processed into thin-walled aluminum cans.

Tube industry

3003 aluminum slug can be used to produce aluminum hoses, such as toothpaste tubes, medical packaging tubes, paint tubes, etc. These hoses are lightweight and have excellent corrosion resistance.

Bottle caps and containers

3003 aluminum slug is often used to make bottle caps and container closures, such as wine bottle caps, beverage bottle caps, etc., to ensure sealing and appearance quality.

Electronic components

In the electronics industry, 3003 aluminum slug can be processed into capacitor housings, electrical housings and radiators to improve the heat dissipation performance of equipment.

Automotive industry

3003 aluminum slug is also used to produce fuel filters, oil filters and other automotive parts.

3003 aluminum slug surface treatment

Mill finish

Mill finish is the original state of the aluminum surface without any subsequent treatment, also known as the "rolled surface" or "factory surface".

Shot blasting

Shot Blasting is a process that uses high-speed abrasive particles to clean or strengthen metal surfaces. This method uses mechanical equipment to spray metal shots or other particles at high speed onto the surface of the workpiece to remove impurities, strengthen the material or improve the surface texture.

Tumbled

Tumbled refers to a process of surface processing of materials or workpieces through tumbling process. This process usually involves placing the workpiece and abrasive together in a rotating drum or vibrating machine to achieve the effect of cleaning, polishing or deburring through physical friction, impact and grinding.

Below is the effect of three surface treatments of 3003 aluminum slug:

3003 aluminum slug case display

3003 aluminum slug packaging delivery

Our products are packaged according to the wishes of our customers and our capabilities. Chalco's standard packaging method consists of packing the blocks in cardboard boxes weighing approximately 25 kg, which are then stacked on wooden pallets. The pallets are then covered with PE foil and wrapped with stretch foil. Special packaging in metal boxes is also possible by agreement.

3003 aluminum slug production process

- Raw material smelting: Melt high-purity aluminum ingots to ensure that the alloy composition meets the 3003 standard.

- Casting and rolling: Molten aluminum is made into medium and thick aluminum plates through the casting and rolling process.

- Hot rolling: The aluminum plate is heated and rolled to a thinner thickness to improve internal uniformity.

- Cold rolling: Further thinning the aluminum plate to ensure dimensional accuracy and surface finish.

- Stamping: Use a die to stamp the aluminum plate and process it into a round or oval billet.

- Deburring: Remove the burrs on the stamping edge through mechanical grinding to ensure smooth edges.

- Annealing: Anneal the billet to improve ductility and formability.

- Surface cleaning: Use pickling or polishing to remove the surface oxide layer to ensure that the billet is clean.

- Dimension detection: Strictly measure the diameter, thickness and other dimensions of the billet.

- Performance testing: Test the tensile strength, ductility and other properties to ensure that they meet quality standards.

- Packaging and warehousing: Qualified aluminum billets are protectively packaged and ready for delivery or storage.

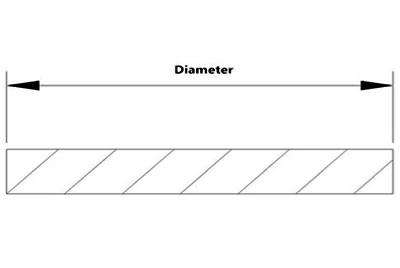

3003 aluminum slug diameter and thickness tolerance

Chalco's 3003 aluminum slug products strictly adhere to the following tolerances to ensure dimensional accuracy.

Thickness tolerance

| Thickness(mm) | Tolerance(mm) |

| 0.8-3.5 | +/- 0.05 |

| 3.5-6.5 | +0.05, -0.03 |

| 6.5-8.5 | +-0.05 |

| 8.5-17 | +0.08, -0.05 |

| 17-25 | +0.08, -0.05 |

Diameter tolerance

| Diameter(mm) | Tolerance(mm) |

| 3-20 | +0.05, -0.03 |

| 20-60 | +/- 0.05 |

| 60-220 | +0.07, -0.05 |

3003 aluminum slug cross section

Other types

Why choose Chalco's 3003 aluminum slug?

Free samples: Free samples are sent to customers. Customers can place orders after passing performance tests, so they can buy with confidence.

Discount surprise: Old customers or large-volume customers can enjoy discount surprise prices, which are more competitive.

Quality inspection certificate: Various quality inspection reports are provided according to customer requirements to ensure product quality.

Accurate size: Chalco has various advanced size verification equipment to ensure dimensional accuracy and tolerance range.