The 6063 aluminum slug offers high strength, excellent anodizing properties, corrosion resistance, and a smooth finish, making it outstanding for stamping applications with complex shapes.

Chalco's 6063 aluminum slugs, with their superior dimensional accuracy and consistent weight specifications, significantly reduce manufacturing costs for customers.

6063 aluminum slug specifications

Standards:EN 570, EN 573, EN 755, EN 754

Certifications:ISO 9001, ISO 14001, ISO 45001, IATF 16949, CE, RoHS

Chalco ensures a zero-defect quality commitment through advanced processes, helping you optimize costs and enhance competitiveness.

6063 aluminum slug shapes and sizes

- Shapes: Flat round, dome shape, oval, rectangular, hole-punched round

- Temper: O-H112

- Thickness Range: 2 - 30mm

- Diameter Range: 10 - 200mm

- Surface Treatment: Mill Finish, Glossy Polishing, Rolling, Shot Peening, Sandblasting

- Weight: Individual weight depends on diameter and thickness (precise weight control)

- Tolerances: Strict adherence to dimensional tolerances for precision manufacturing

| Common 6063 Aluminum Slug Diameter Chart | ||

| Small Size | Medium Size | Large Size |

| 20 mm | 40 mm | 74 mm |

| 25 mm | 45 mm | 85 mm |

| 27 mm | 50 mm | 89 mm |

| 54 mm | 90 mm | |

| 63.5 mm | 116 mm | |

Products and applications of 6063 aluminum slug

Due to its excellent mechanical properties and ease of extrusion, 6063 aluminum slug is widely used in the manufacturing of items such as hoses, aerosol cans, beer bottles, aluminum bottles, capacitor housings, and automotive parts.

Round Slug & A/C Muffler

Round Slug & Bumper Sensor

Rectangle: Narrow Radius Slug & Heat Sink

Round Slug &Air Bag Component

Large Center Hole Slug &Transmission Piston

Round Slug &Piston Component

Round Slug & Medical Device Component

Concave Slug & Receiver/ Dryer

Round Slug & Fire Extinguisher

Narrow Center Hole Slug & Suspension Component

Concave Slug & Clutch Component

Multiple Radius Slug

In the global market, our products hold a significant market share and are widely used in the production of beer bottles for well-known brands such as Qingdao Beer and Carlsberg, demonstrating our quality and industry trust.Quick Quote

Performance of 6063 aluminum slug

The 6063 aluminum slug combines strength, corrosion resistance, and machinability, making it a versatile and stable high-quality material.

- Tensile Strength: 140 MPa

- Yield Strength: 110 MPa

- Elongation: Up to 20%

- Hardness: 60 HB - 70 HB

- Grain Size/mm²: 30 - 50

Surface treatment options for 6063 aluminum slug

To enhance the adhesion of lubricants or oils and improve stamping efficiency, while also maintaining the product's appearance quality, we offer the following specialized surface treatment services.

-

Mill Finish

Mill FinishThe aluminum slug is untreated, maintaining its original rolled state. The surface is smooth but not glossy.

-

Tumbling

TumblingThe aluminum slug is tumbled with abrasives in a drum, effectively removing surface burrs and oxide layers, while increasing surface roughness.

-

Shot Peening

Shot Peening5083 aluminum alloy has strong corrosion resistance, can withstand extremely low temperature, and is suitable for application and low -temperature storage tanks in the ocean.

-

Sandblasting

SandblastingThe aluminum slug surface is cleaned using high-speed sand blasting, removing oxide layers and impurities, while increasing surface roughness.

-

Anodizing

AnodizingAn oxide film is formed on the surface of the aluminum slug through an electrochemical process, enhancing corrosion resistance and improving aesthetics.

-

Polishing

PolishingThe surface of the aluminum slug is mechanically or chemically polished to achieve a mirror-like finish.

Chemical elements of 6063 aluminum slug

| Chemical Element | % Present |

| Si | 0.20 - 0.60 |

| Fe | 0.35 max |

| Cu | 0.10 max |

| Mn | 0.10 max |

| Mg | 0.45 - 0.90 |

| Cr | 0.10 max |

| Zn | 0.10 max |

| Ti | 0.10 max |

| Other (Each) | 0.05 max |

| Others (Total) | 0.15 max |

| Aluminium (Al) | Remainder |

Advantages of 6063 aluminum slug

- Ideal for extrusion processes and easily stamped into complex shapes.

- High strength and low density, making it suitable for applications requiring both strength and portability.

- Can undergo various surface treatments, such as anodizing, to enhance appearance and corrosion resistance.

- Suitable for harsh environments like outdoor and marine conditions, ensuring long-lasting durability.

- Fully recyclable without compromising quality, supporting the concept of a circular economy, and is environmentally friendly and cost-effective.

- High thermal conductivity and electrical conductivity, making it suitable for applications such as heat exchangers and electronic components.

Dimensional tolerance of 6063 aluminum slug - EN 570

We offer customized production services for 6063 aluminum slugs, with tolerance requirements fully processed according to customer specifications and needs, ensuring precise dimensions.

Diameter tolerance of 6063 aluminum slug

| Slug diameter | Tolerances | |

| over | up to | |

| - | 10 | ± 0.02 |

| 10 | 40 | ± 0.03 |

| 40 | 60 | ± 0.04 |

| 60 | 80 | ± 0.05 |

| 80 | 120 | ± 0.06 |

| 120 | 150 | ± 0.08 |

| 150 | 200 | ± 0.10 |

Thickness tolerance of 6063 aluminum slug

| Slug diameter | Tolerances | |

| over | up to | |

| - | 2.8 | ± 0.03 |

| 2.8 | 6.5 | ± 0.05 |

| 6.5 | 8.5 | ± 0.07 |

| 8.5 | 10.5 | ± 0.10 |

| 10.5 | 15 | ± 0.14 |

| 15 | 20 | ± 0.18 |

| 20 | 25 | ± 0.22 |

| 25 | 30 | ± 0.26 |

| 30 | 40 | ± 0.30 |

Packaging of 6063 aluminum slug

- The aluminum slugs are transported via conveyor belts to the fully automated packaging line.

- Packed in cardboard boxes with a weight of 25 kg per box, each box is precisely weighed, labeled with customer information and product identification codes.

- Every 40 boxes are stacked onto wooden pallets (total weight of 1, 000 kg) and wrapped with plastic film to prevent moisture, making them suitable for export shipping.

- Packaging can also be customized according to customer requirements to ensure safe storage and transportation.

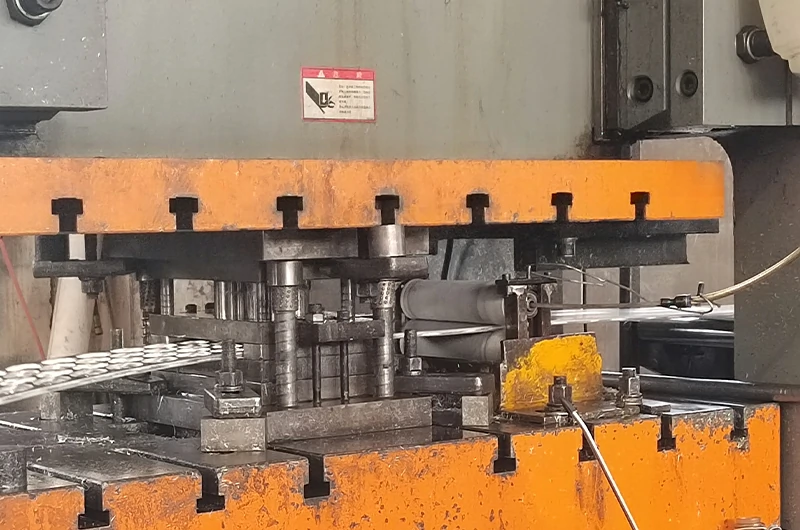

Production of 6063 aluminum slug

Continuous casting and rolling - stamping process

- High-purity aluminum ingots are melted and purified to ensure the quality of the aluminum melt.

- After continuous casting into narrow or thin strips, the material is hot-rolled and cold-rolled to the required thickness.

- The aluminum slug is stamped at high speed using automatic stamping machines, with a stamping rate of up to 300 times per minute.

- Annealing is performed to adjust hardness and improve machinability.

- Sandblasting, rolling, or vibration treatments are applied as needed to ensure a smooth surface.

The continuous casting and rolling - stamping process is ideal for producing standardized, large-volume thin aluminum slugs with high efficiency and low cost.

Aluminum bar saw cutting process

- The molten aluminum is cast into aluminum bars using molds, and then cut to the required dimensions with a high-precision saw.

- Annealing is done to adjust hardness, and surface treatments (such as sandblasting or rolling) are applied as required.

The aluminum bar saw cutting process is suitable for producing non-standard thick aluminum slugs or high-end products, offering strong flexibility.

Production capabilities

Using advanced equipment, including melting furnaces, continuous casters, hot rolling mills, cold rolling mills, stamping machines, annealing furnaces, and vibrators, we ensure efficient production and stable quality.

Why choose chalco?

- We offer customized aluminum slugs in various sizes, shapes, surface treatments, and specifications according to customer requirements.

- We use precision weight grading machines to monitor the weight and dimensions of each aluminum slug in real time, ensuring outstanding performance in stamping, drawing, and other processes.

- Only high-purity aluminum ingots are used, with no secondary scrap materials, ensuring the quality and environmental properties of the aluminum slugs.

- With an annual production capacity of 18, 000 tons, we support the production of over 200 standard sizes of aluminum slugs to meet global market demand.

- We respond to inquiries within 24 hours, offering free samples and technical support.

How to quickly order 6063 aluminum slug?

To expedite our response to your inquiry, we kindly ask you to provide the following information:

- Size (Drawings will result in a faster quote)

- Temper (e.g., O or H18)

- Surface Treatment (Rolling or Sandblasting)

- Shape (Flat or Dome)

- Quantity

- Required delivery time

- Delivery country or region

Popular products related to 6063 aluminum slug

We not only focus on producing 6063 aluminum slugs but also offer 1050, 1060, 3003, 6061, and 6063 aluminum slugs to meet the needs of various application fields.