6061 T6 aluminum square tubing offers ease of machining, excellent welding properties, and good corrosion resistance. It is commonly used for structural components, machine parts, and fixtures, among other applications. 6061 T6 aluminum square tubing is available in both full sizes and custom-cut lengths.

Standard specifications

ASTM B221, AMS-QQ-A-200/8

Chalco's stock of 6061 T6 aluminum square tubing sizes

Chalco stocks 6061 aluminum square tubing with guaranteed lowest prices, seven-day delivery, and no minimum order quantity requirement. Click to order

| Alloy Temper | Width(in) | Wall(in) |

| 6061-T6 | 5.906 | 0.394 |

| 6061-T6 | 6 | 0.374 |

| 6061-T6 | 6 | 0.5 |

| 6061-T6 | 7.244 | 0.315 |

| 6061-T6 | 7.874 | 0.394 |

| 6061-T6 | 7.874 | 0.591 |

| 6061-T6 | 7.874 | 0.787 |

| 6061-T6 | 8 | 0.374 |

| 6061-T6 | 8 | 0.5 |

| 6061-T6 | 9.843 | 0.394 |

Chalco's hot-selling products in 6061 T6 aluminum square tubing

| Alloy Temper | Width(inch) | wall(inch) |

| 6061-T6 | 0.5 | 0.065 |

| 6061-T6 | 0.75 | 0.065 |

| 6061-T6 | 0.75 | 0.125 |

| 6061-T6 | 1 | 0.065 |

| 6061-T6 | 1 | 0.125 |

| 6061-T6 | 1 | 0.095 |

| 6061-T6 | 1.25 | 0.095 |

| 6061-T6 | 1.25 | 0.125 |

| 6061-T6 | 1.5 | 0.065 |

| 6061-T6 | 1.5 | 0.09 |

| 6061-T6 | 1.5 | 0.095 |

| 6061-T6 | 1.5 | 0.125 |

| 6061-T6 | 1.5 | 0.188 |

| 6061-T6 | 1.5 | 0.25 |

| 6061-T6 | 1.75 | 0.095 |

| 6061-T6 | 1.75 | 0.125 |

| 6061-T6 | 2 | 0.065 |

| 6061-T6 | 2 | 0.095 |

| 6061-T6 | 2 | 0.125 |

| 6061-T6 | 2 | 0.188 |

| 6061-T6 | 2 | 0.25 |

| 6061-T6 | 2.5 | 0.125 |

| 6061-T6 | 2.5 | 0.188 |

| 6061-T6 | 2.5 | 0.25 |

| 6061-T6 | 3 | 0.125 |

| 6061-T6 | 3 | 0.188 |

| 6061-T6 | 3 | 0.25 |

| 6061-T6 | 3.5 | 0.25 |

| 6061-T6 | 4 | 0.125 |

| 6061-T6 | 4 | 0.188 |

| 6061-T6 | 4 | 0.25 |

| 6061-T6 | 4 | 0.375 |

| 6061-T6 | 4 | 0.5 |

| 6061-T6 | 5 | 0.188 |

| 6061-T6 | 5 | 0.25 |

| 6061-T6 | 6 | 0.125 |

| 6061-T6 | 6 | 0.188 |

| 6061-T6 | 6 | 0.25 |

| 6061-T6 | 8 | 0.25 |

The manufacturing method for 6061 T6 aluminum square tubing

Extrusion

This is a common manufacturing method, involving the heated 6061 aluminum alloy billet being extruded into a die with a square cross-sectional shape using high pressure. The raw material is shaped into the form of a square tube and then cut and trimmed to the desired dimensions after cooling.

Welding

This method uses 6061 aluminum sheets or coils, which are joined together using various welding techniques to form square tubing. Common welding methods include TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and electron beam welding. After welding, the tubing requires trimming and quality inspection.

Casting

The casting method is suitable for manufacturing square tubing with larger sizes and special requirements. In this method, aluminum alloy is melted and then poured into a square mold. After cooling, it takes on the structure of square tubing.

Drawing

This method involves stretching a 6061 aluminum alloy billet through a square die to gradually form the cross-section of the square tubing. It is typically used for manufacturing smaller-sized square tubing, achieving the desired dimensions and shape through multiple extrusion passes.

Mechanical properties of 6061 T6 aluminum square tubing

| Density | 2.7 g/cm3 |

| Tensile Strength | 310 MPa |

| Yield Tensile Strength | 276 MPa |

| Shear Strength | 207 MPa |

| Elongation | 12% |

| Melting Point | 582 - 652°C |

Characteristics of 6061 T6 aluminum square tubing

High strength: 6061 aluminum alloy exhibits excellent strength, particularly when in the heat-treated (T6) condition.

Excellent corrosion resistance: it has good corrosion resistance, especially exhibiting good tolerance to most atmospheric conditions and common chemical media.

Machinability: easily cut, shaped, and welded, suitable for various machining processes, providing manufacturing flexibility.

Good heat treatment properties: strength can be improved through heat treatment while maintaining high toughness.

Versatility: suitable for various applications, including aerospace, automotive manufacturing, construction, electronics, sports equipment, and more.

Weldability: exhibits good welding characteristics, suitable for various types of welding methods, such as TIG welding, MIG welding, and arc welding.

Applications of 6061 T6 aluminum square tubing

Aerospace: used for manufacturing aircraft components, spacecraft structures, and aerospace components.

Automotive industry: utilized in the production of automobile chassis, wheels, body structures, and engine components.

Bicycle manufacturing: commonly employed for bicycle frames, handlebars, and other bicycle components.

Shipbuilding: applied in the manufacture of ship structures, hulls, and maritime equipment.

Construction: used in building structures, window frames, handrails, and stairs, among others.

Electronics: including computer casings, heat sinks, and enclosures for electronic devices.

Sports and Recreation Equipment: Employed in the production of skateboards, snowboards, and other outdoor gear.

Industrial equipment: utilized for manufacturing machinery components, conveyor belts, and other industrial equipment.

Stage and stage equipment: widely used in stage production, sound equipment, and exhibitions.

Considerations when purchasing 6061 aluminum square tubing

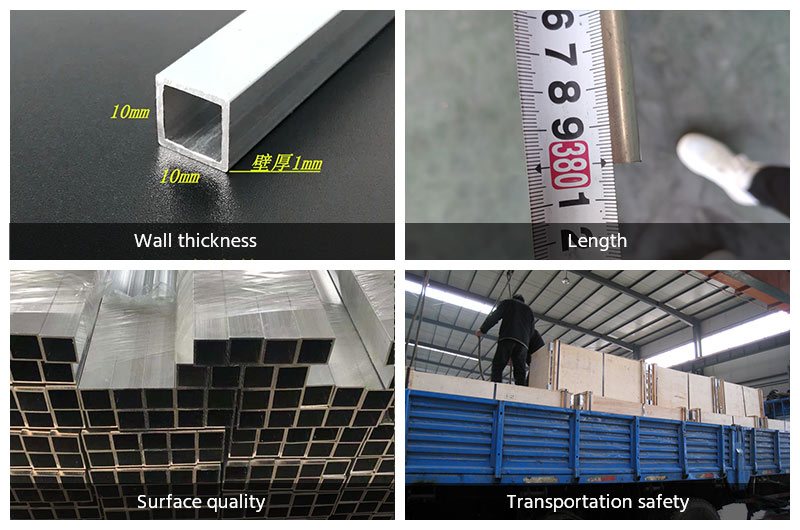

Specifications and dimensions: determine the specifications and dimensions you need for 6061 aluminum square tubing, including length, width, thickness, and more. This depends on your specific application requirements.

Alloy type: 6061 aluminum alloy comes in different hardness and performance grades. Choose the appropriate alloy type to meet your application needs.

Quality certification: ensure that the purchased aluminum square tubing complies with relevant quality certifications and standards. This can guarantee the product's quality and performance.

Supplier reputation: choose reputable suppliers or manufacturers who typically offer higher-quality products and better customer support.

Price comparison: obtain quotes from multiple suppliers and compare prices and delivery terms to ensure you get the most competitive deal.

Delivery time: ensure that the supplier can provide the needed aluminum square tubing according to your schedule, especially for urgent projects.

Packaging and shipping: ensure that the aluminum square tubing is properly packaged and protected during transport to prevent damage or corrosion.