6061 aluminum alloy is a high-strength aluminum alloy with aluminum (Al) as the matrix and magnesium (Mg 0.8-1.2%) and silicon (Si 0.4-0.8%) as the main alloying elements. It has good corrosion resistance, machinability and welding performance, and is widely used in aerospace, automobile manufacturing, building structures, mechanical equipment and other fields.

Chalco can supply 6061 aluminum alloy in different states such as O, T4, T5, T6, T651, etc., and supports customized processing such as cutting, drilling, bending, welding, laser cutting, anodizing, tinning, etc. to meet different application requirements, and provides the most complete product types of 6061 aluminum alloy:

Chalco 6061 aluminum temper detailed explanation

Chalco 6061 aluminum alloy can show different mechanical properties, processing properties and application fields according to different heat treatment (Temper) states. The heat treatment methods of 6061 aluminum alloy mainly include T series (T4, T5, T6, T651, etc.) and O state (annealing state). These different treatment methods affect the strength, hardness, toughness and machinability of the alloy.

6061 T6 temper ——solution heat treatment + artificial aging (highest strength, most widely used state)

| Features | Typical Applications |

| The most common state of 6061 aluminum alloy Highest strength, high hardness, excellent corrosion resistance Suitable for high load bearing structures | Aerospace: wings, frames, brackets Automobile manufacturing: chassis, engine brackets, suspension systems Shipbuilding industry: hull frame, corrosion-resistant parts Mechanical equipment: mold substrates, industrial machinery parts |

6061 T651 temper ——solution heat treatment + artificial aging + stress relief

| Features | Typical Applications |

| Remove internal stress based on T6 and reduce processing deformation Suitable for applications requiring high-precision machining High dimensional stability, can be used for precision parts processing | Mold manufacturing: high-precision mold substrate Aerospace parts: high-precision aviation structural parts Precision machining: CNC machining parts, rail transportation equipment |

6061 T6511 temper —— upgraded version of T651

| Features | Typical Applications |

| Based on T651, straightening treatment is performed on extruded materials Better machining performance, suitable for high-precision extrusion profiles | Rail transit: car body frame, track equipment Construction industry: curtain wall profiles, door and window structures Shipbuilding: hull beams, ship support structures |

6061 T62 temper —— reheat treated after cold working

| Features | Typical Applications |

| Similar to T6, but with better toughness and ductility Suitable for reprocessing after deep drawing, cold drawing and bending | Automotive industry: body structural parts requiring additional processing Aerospace: Stretchable airframe materials Shipbuilding: Structural support parts |

6061 T4 temper ——solution heat treatment + natural aging

| Features | Typical Applications |

| The intensity is between O state and T6 Good processability, bending performance is better than T6 Suitable for occasions where secondary processing (welding, bending, forming) is required | Automobile manufacturing: frame, wheel hub, support beam Building structure: aluminum door and window frames, curtain wall brackets Aerospace: Lightweight structural parts |

6061 O temper —— fully annealed state

| Features | Typical Applications |

| Lowest strength, but highest ductility Suitable for applications requiring bending, deep drawing, cold working Soft, easy to weld and machine | Aerospace: flexible parts, pipes, sealing components Automobile industry: shock-absorbing structures, body panels Ships: Welded structures |

Chalco 6061 aluminum products list

6061 aluminum alloy has been widely used in many industries due to its high strength, excellent corrosion resistance and good processing performance. In order to meet the needs of different fields, we provide a variety of 6061 aluminum alloy products, including aluminum plates, aluminum bars, aluminum tubes, aluminum bars, aluminum profiles, aluminum forgings, aluminum wires, etc., suitable for various structural parts, mechanical parts and industrial applications.

6061 aluminum sheet plate coil

Popular thickness range: 0.01 ” (0.2mm) to 9.84 ” (250mm)

Standard size aluminum sheet: 48 ” x 144 ” ; can be purchased in 12 ” x 48 ” increments (12 ” x 48 ” , 24 ” x 48 ” , 36 ” x 48 ” , etc.)

Specification: ASTM.B209, AMS.4027, AMS-QQ-A-250/11, AMS.4025, ASTM B209, DIN EN 485-2, GB/T 3190

Good machinability: suitable for welding, drilling and other processing methods

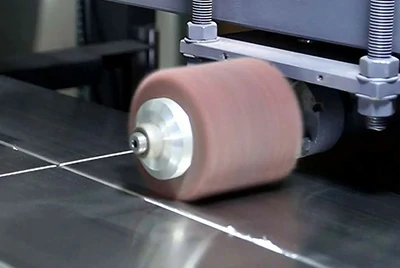

Excellent surface treatment performance: provide anodizing , coating, electroplating , brushing, polishing, mirror and other surface treatments

Chalco 6061 aluminum plate some featured products display

6061 aluminum bare sheet

Thin aluminum sheets (0.2mm - 6mm) are suitable for electronic products, automobile casings, aviation interiors, etc.

6061 aluminum clad sheet

Pure aluminum cladding increases corrosion resistance

Width of aluminum coil can reach 2650mm and can be cut to any size

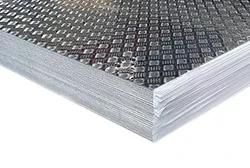

6061 aluminum tread plate

With anti-slip texture, high strength and corrosion resistance, it is widely used in floor paving, stair treads, industrial platforms and other scenes.

6061 al diamond plate

The diamond pattern design enhances the anti-slip performance and is suitable for truck boxes, decorative panels, mechanical protection, etc.

High precision, good stability, easy machining, commonly used in mold manufacturing, fixture base plates, CNC processing parts and other applications.

Explore more 6061 aluminum sheet, aluminum coil products and stock sizes, click to view [6061 aluminum sheet coil details]

6061 aluminum bar rod

6061 aluminum round bar: diameter 4mm to 300mm, largest up to 1350mm

6061 aluminum square bar: size 6-50mm

6061 aluminum hex bar: across flat 12-65mm; Length 100-2500mm

Specification: ASTM B211, AMS 4115, AMS 4116, AMS 4117, AMS 4128, AMS-QQ-A-225/8 and ASTM B221, AMS4150, AMS 4160, AMS 4161, AMS-QQ-A-200/8

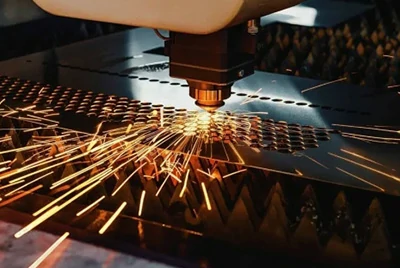

Good machinability: suitable for cutting, turning, drilling, welding, laser cutting and other processes

Good surface treatment performance: can provide anodizing, electroplating and other surface treatment

Chalco 6061 aluminum bar part of the featured product display

6061 aluminum cold drawn bar

6061 aluminum threaded bar

Explore more 6061 aluminum bar products and stock sizes, click to view [6061 aluminum bar details] [6061 aluminum bar stock pdf download]

6061 aluminum tube

6061 extruded aluminum tube diameter: 0.314” -17.71” (3-450mm)

6061 cold drawn aluminum tube diameter: 0.2” -10. 23” (5-260mm)

6061 forged aluminum tube diameter: 7.87 ” -39. 37” (200-1000mm)

Specification: WW-T-700/6, ASTM B241, ASTM B429, AMS-QQ-A-200/8, ASTM B221, AMS 4079, AMS 4081, AMS 4082, AMS 4083, MIL-T-7081, EN 2392

Good machinability: suitable for welding, cutting, bending, drilling , laser cutting and other processing methods

Excellent surface treatment performance: can provide oxidation, electroplating, coating and other surface treatment

Chalco 6061 aluminum tube part of the featured product display

6061 aluminum large diameter tube

Outer diameter reach es 1320mm

6061 aluminum thin wall tube

OD: 3.54-11.81"(90-300mm); WA: 0.01″-2″(0.25-50mm)

6061 aluminum seamless tube

OD: 3.54-15.74"(90-400mm); WA: 0.2"-0.79"(5-20mm)

Explore more 6061 aluminum tube products and stock sizes, [6061 aluminum tube stock pdf download]

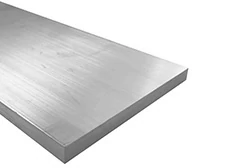

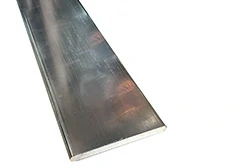

6061 aluminum flat bar

Thickness: 0.08"-9.8"(2-250mm)

Width: 0.2"-11.8"(5-300mm)

Specification: ASTM B317, ASTM B236, IEC 60105, ISO 209-1, 2, DIN EN 755-2, DIN EN 755-5:2008-06, ASTM B221, AMS-QQ-A-200/8

Balance of conductivity and processing performance: While ensuring a certain conductivity, it also has high strength and excellent processing performance. It is suitable for application scenarios that require both current transmission and mechanical strength and structural support.

Easy to process: suitable for cutting, welding, bending, drilling and other processing methods

Excellent surface treatment performance: can be anodized, tinned , sprayed, etc.

Chalco 6061 aluminum bar partial featured product display

6061 thick plate cutting aluminum flat bar

6061 extruded aluminum bar

6061 tinned aluminum busbar

Explore more 6061 aluminum bar products and stock sizes, click to view [6061 aluminum flat bar details] [6061 aluminum flat bar stock pdf download]

6061 aluminum extrusion

6061 aluminum profile is a high-strength, corrosion-resistant, weldable aluminum alloy profile, which is widely used in aerospace, rail transportation, automobile manufacturing, construction engineering, industrial equipment and other fields. Due to its excellent mechanical properties, good processability and lightweight characteristics, it has become an ideal choice for structural parts, mechanical accessories and frame materials in many industries.

6061 industrial profile

Mechanical equipment frame, automation equipment bracket, assembly line frame

6061 building profile

Curtain walls, door and window frames, structural supports, guardrails

6061 radiator profile

Electronic heat sinks, LED lamp radiators, power equipment

6061 guardrail profile

Building decoration, handrails, railings, frames

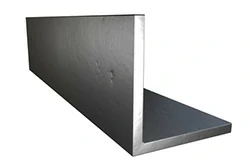

6061 angle profile

Mechanical support, building reinforcement

6061 channel profile

Special structural parts, connecting brackets, auto parts

6061 T bar

6061 L bar

6061 F bar

Explore more 6061 aluminum extrusion products and stock sizes, click to view [6061 aluminum extrusion details]

6061 aluminum forgings

Conventional maximum diameter: outer diameter of quenched parts≤2500mm, outer diameter of non-quenched parts≤4000mm;

Patented technology maximum outer diameter: with an outer diameter of up to 10m;

Forging production lines: 3 forging production lines, 1500 tons, 1000 tons, 630 tons, 160 tons presses

Specification: AMS4311F ASTM-B247-15 ASTM-B594 CLASS A, UNE-EN 573-3 UNE-EN 10204

High strength and hardness: Heat-treated and strengthened, with excellent tensile strength and impact resistance

Dense structure and no pores: Forging process makes the material more compact, reduces internal defects and improves fatigue life

Excellent machinability: easy to process by cutting, welding, drilling, polishing, surface treatment, etc.

Excellent wear and fatigue resistance: suitable for highly loaded mechanical parts

6061 forged ring

6061 forged disc

6061 forged shaft

6061 forging block

6061 forged plate

6061 special shape forgings

Explore more 6061 aluminum forging products and forging capabilities, click to view [6061 aluminum forging details]

6061 aluminum wire

6061 aluminum wire is a high-strength, corrosion-resistant, and highly processable aluminum alloy wire, which is widely used in aerospace, automobile manufacturing, power transmission, electronic equipment, welding filler materials, and other industries. Compared with pure aluminum wire, 6061 aluminum wire has higher mechanical strength and corrosion resistance while taking into account certain electrical conductivity, and is suitable for high-strength structural parts, electrical connections, fasteners, and other application scenarios.

Good processing performance: suitable for cutting, wire drawing, welding, surface treatment and other processing methods

Moderate conductivity: can be used for electrical connections, grounding wires, electronic equipment, etc.

Lightweight design: low density, which can reduce the overall weight of the equipment and improve energy efficiency

Excellent wear and fatigue resistance: suitable for highly loaded mechanical parts

6061 aluminum round wire

6061 aluminum flat wire

6061 fastener aluminum wire

6061 aluminum rivet wire

6061 transformer winding wire

6061 spring wire

Explore more 6061 aluminum wire products, click to view [6061 aluminum wire details]

Chalco 6061 aluminum production capacity

Chalco has advanced aluminum alloy production equipment and a strict quality control system to ensure that 6061 aluminum alloy products have excellent strength, corrosion resistance and stable processing performance, meeting the strict requirements of aerospace, automobile manufacturing, construction, industrial equipment and other fields.

Production equipment & technical capabilities

- Large casting equipment: Direct reading spectroscopy analysis and online degassing filtration are used to ensure stable alloy composition and pure materials

- Advanced extrusion production line: equipped with 800T-10, 000T extruders, capable of producing various 6061 aluminum bars, aluminum tubes, and aluminum profiles

- Hot rolling & cold rolling production line: using precision rolling technology to ensure the smooth surface and precise size of aluminum plates and aluminum bars

- Forging equipment: using free forging, die forging, ring rolling and other processes to produce high-performance aluminum forgings

- Heat treatment & aging treatment: With T4, T5, T6, T651 and other heat treatment capabilities to ensure that the material achieves optimal performance

Quality control & certification

- Strictly implement international standards: production complies with ASTM, GB/T, ISO and other industry standards

- Full-process testing system: ultrasonic flaw detection, tensile testing, hardness testing, and metallographic analysis are used to ensure stable product quality

- Environmental and safety certification: Comply with RoHS and REACH environmental protection requirements to meet the global market demand for green materials

Chalco 6061 aluminum product additional service

Chalco not only provides high-quality 6061 aluminum alloy materials, but also has a complete processing service system, covering machining, laser cutting, surface treatment, welding, stamping and forming processes to meet the personalized needs of different customers.

Machining

We have advanced machining centers that provide high-precision 6061 aluminum alloy processing, including:

- CNC 6061 aluminum: Using CNC machining (CNC) technology, it can perform precision cutting, drilling, tapping, milling, turning

- Laser cutting 6061 aluminum: High-precision laser cutting ensures neat edges and precise dimensions

- Customized parts processing: suitable for aviation, automobile, electronic equipment, mold manufacturing and other industries

Surface treatment

Provide a variety of surface treatment processes to enhance the corrosion resistance, aesthetics and functionality of 6061 aluminum alloy:

- 6061 anodized aluminum: Enhanced corrosion resistance, surface hardness, and can be processed in a variety of colors

- Coatings: Provide spraying, galvanizing, nickel plating, PVD, CVD and other processes to improve wear resistance and decorative effects

- Sandblasting: removes the oxide layer, increases roughness, and improves adhesion

- Polishing: Provide mirror polishing and electrolytic polishing, suitable for high-end decoration and precision equipment

Welding 6061 aluminum

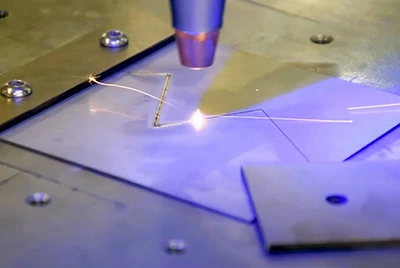

- Laser welding 6061 aluminum: high-precision laser welding, suitable for aerospace and electronic equipment

- MIG welding 6061 aluminum: gas shielded welding (MIG welding), suitable for structural parts and automotive parts

- TIG welding 6061 aluminum: Tungsten inert gas welding (TIG welding), suitable for high-precision welding applications

- Dissimilar Aluminum Welding: Welding 3003 to 6061; Welding 5052 to 6061; Welding 6061 to 6063

- Welding filler material selection: 5356 welding wire , 4043 welding wire , etc.

Stamping and forming

- Deep drawing 6061 aluminum (deep stamping): suitable for aviation, automotive parts, pressure vessels

- Bending 6061 aluminum: Suitable for brackets, rails, and structural parts

Chalco supports processing according to drawings, and provides one-stop services such as customized cutting, forming, surface treatment, welding, etc., and relies on efficient production capacity and global logistics network to ensure short-term delivery to meet industrial production needs. With advanced processing equipment and professional technical team, we are committed to providing customers with high-precision and high-quality 6061 aluminum alloy processing solutions. Welcome to consult and customize!

Chalco 6061 aluminum cooperation areas

6061 aluminum for aerospace

Chalco has long supplied high-quality 6061 aluminum alloy for aerospace, working with major aviation manufacturers and projects. Certified to AMS, ASTM, and GB standards, 6061 is widely used in fuselage, wings, engines, interiors, and electronics for aircraft, spacecraft, and drones.

Contact us now

Click to view application case details

6061 aluminum for marine ships

Chalco supplies high-quality 6061 aluminum alloy for marine and shipbuilding industries, with CCS, DNV, and ABS-certified products. Known for seawater corrosion resistance, strength, and processability, 6061 is used in hulls, decks, handrails, accessories, and propulsion systems.

Contact us now

Click to view application case details

6061 aluminum for automobile

Chalco provides high-performance 6061 aluminum alloy for the automotive industry, meeting ISO/TS 16949 standards. Widely used in bodies, chassis, power systems, and wheels, 6061 helps reduce weight and improve fuel efficiency and safety for EVs, passenger cars, and commercial vehicles.

Contact us now

Click to view application case details

6061 aluminum for sporting goods

Chalco provides high-strength, corrosion-resistant 6061 aluminum alloy, which is widely used in bicycles, outdoor equipment and sports equipment to meet the needs of lightweight and high strength. Its excellent strength-to-weight ratio, durability and machinability make it an ideal choice for high-end sports equipment.

Contact us now

Click to view application case details

- 6061 aluminum bicycle tube

- 6061 aluminum tent pole

6061 aluminum for power energy

6061 aluminum alloy has good conductivity, mechanical strength and environmental corrosion resistance, and is suitable for high-load power transmission and support structures.

Contact us now

Click to view application case details

6061 aluminum for hydraulic equipment

6061 aluminum alloy has excellent compression resistance, fatigue resistance and good machinability, suitable for high-pressure, high-strength hydraulic equipment, ensuring stable operation of the system and extending service life.

Contact us now

Click to view application case details

- 6061 cylinder tube

-

6061 aluminum air piping - 6061 pipe for pressure vessel

6061 aluminum for architectural decoration

6061 aluminum has excellent weather resistance, machinability and surface treatment adaptability, which can meet the lightweight, aesthetic and structural stability requirements of modern buildings.

Contact us now

6061 knowledge center

6061 aluminum technical parameters

| Alloy 6061 chemical composition Spec: BS EN 573-3:2009 | |

| Chemical Element | % Present |

| Manganese (Mn) | 0.0 - 0.15 |

| Iron (Fe) | 0.0 - 0.70 |

| Magnesium (Mg) | 0.80 - 1.20 |

| Silicon (Si) | 0.40 - 0.80 |

| Copper (Cu) | 0.15 - 0.40 |

| Zinc (Zn) | 0.0 - 0.25 |

| Titanium (Ti) | 0.0 - 0.15 |

| Chromium (Cr) | 0.04 - 0.35 |

| Other (Each) | 0.0 - 0.05 |

| Others (Total) | 0.0 - 0.15 |

| Aluminium (Al) | Balance |

| Physical Property of 6061 aluminum alloy | |

| Density | 2.70 g/cm³ |

| Melting Point | 650 °C |

| Thermal Expansion | 23.4 x10^-6 /K |

| Modulus of Elasticity | 70 GPa |

| Thermal Conductivity | 166 W/ mK |

| Electrical Resistivity | 0.040 x10^-6 Ω .m |

| Mechanical Property of 6061 aluminum alloy | |

| Proof Stress | 240 Min MPa |

| Tensile Strength | 260 Min MPa |

| Hardness Brinell | 95 HB |

| Extrusions - Up to 200mm Dia. & A/F, 5mm WT for Tube and Prof Spec: BS EN 755-2:2008 | |

6061 aluminum alloy temper selection guide

| Temper Status | strength | Machinability | Bending properties | Corrosion resistance | Main Applications |

| O (Annealed) | Low | high | excellent | excellent | Aviation, automobile, welding structure |

| T4 (Natural Aging) | medium | high | excellent | good | Automobile, building, aviation structure |

| T6 (highest strength) | Highest | generally | Difference | excellent | Aviation, automobile, machinery, shipbuilding |

| T651 (Stress Relief T6) | Highest | medium | Difference | excellent | Precision machinery, molds, aerospace |

| T6511 (upgraded version of T651) | Highest | high | Difference | excellent | Rail transit, construction, ships |

| T62 (heat treatment after cold working) | high | high | excellent | good | Aviation, Automobile, Shipbuilding |

6061 aluminum and 7075 aluminum

6061 aluminum has higher strength, better weldability and corrosion resistance, and is suitable for aviation, automobiles, and building structures.

7075 aluminum has extremely high strength, but poor corrosion resistance and weak weldability. It is suitable for aerospace, high-end machinery, and military applications.

6061 aluminum and 6063 aluminum

6061 aluminum has stronger mechanical properties and is suitable for load-bearing structures, automotive parts, and industrial frames.

6063 aluminum is mainly used for building profiles, doors and windows, decorative frames, and has better processing and surface treatment performance.

6061 aluminum and 5083 aluminum

6061 aluminum has high mechanical strength and is suitable for aviation, automobile and industrial structural parts.

5083 aluminum has strong seawater corrosion resistance and is suitable for ships, marine equipment, and chemical storage tanks.

6061 aluminum and 5052 aluminum

6061 aluminum has higher strength and is suitable for structural parts, machining, and aerospace

5052 aluminum has stronger corrosion resistance and is suitable for highly corrosive environments such as ocean, chemical industry, and oil tanks.