- Advantages of foam aluminum in building decoration

- A brief introduction to aluminum foam products

- Common types of aluminum foam for construction

- Different pore size types of aluminum foam

- Chalco's specialty aluminum foam

- The performance of Chalco aluminum foam for construction use

- Chalco aluminum foam applications in the construction field

- Chalco foam aluminum application case studies

- What services can Chalco provide for you?

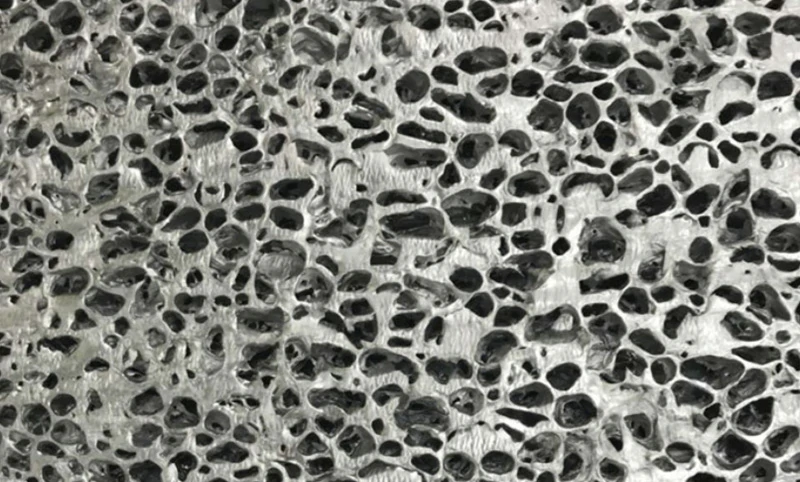

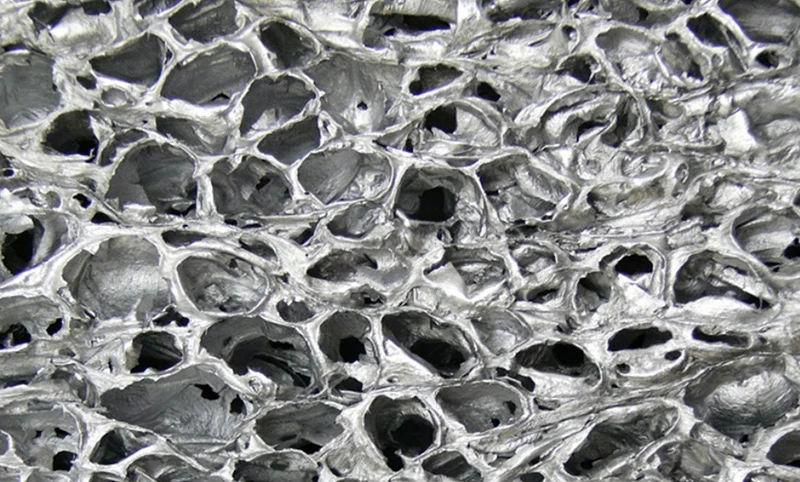

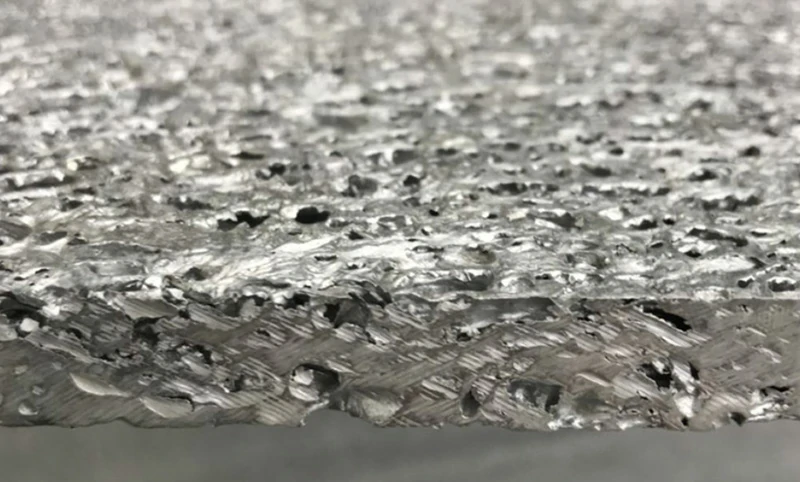

Aluminum foam is a metal material with a porous structure, made from aluminum or aluminum alloys. Its interior is filled with uniformly or non-uniformly distributed pores, creating a sponge-like structure.

This porous structure gives aluminum foam properties such as lightweight, high strength, and excellent energy absorption, making it an important material in the construction industry.

Advantages of foam aluminum in building decoration

- Class A fireproof

- Excellent sound absorption and noise reduction.The sound absorption rate remains above 0.75.

- Various models for diverse design options

- Double-sided perforated panels create stunning light effects through multi-angle refraction

- Lightweight, strong, and easy to install, suitable for high-rise buildings

- Mold-resistant, stain-resistant, indoor use stays colorfast, outdoor use requires no cleaning in rainy areas

- 100% renewable and recyclable, colorless and odorless, harmless to the human body

- Foam aluminum sound barriers outperform traditional ones in patterns, textures, colors, structure, and greenery integration

- Service life of 30-50 years with significantly reduced overall cost

- No perforated cover plate or filling needed, easy to install and construct

A brief introduction to aluminum foam products

Pore size: Distribution from 0.5-10mm, main pore size 5-10mm;

Density: 0.25g/cm³-0.85g/cm³, which is 1/30 of iron, 1/10 of aluminum, and 1/4 of wood;

Types: Open-cell, closed-cell;

Porosity: 70% ~90%;

Specifications: Standard panel size 2400x800x300mm, specific product sizes can be customized according to user requirements.

If you want to learn more about our foams, click on aluminum foam for construction to learn more.

Common types of aluminum foam for construction

Open-cell aluminum foam

Open-cell aluminum foam is a metal foam material with interconnected internal pores, offering excellent air permeability, heat exchange capability, and sound absorption properties. Due to the interconnected pores, it can absorb electromagnetic waves and is widely used in applications such as heat exchangers, soundproof walls, filters, and electromagnetic shielding materials.

Porosity: Typically between 70% and 90%.

Pore size: 0.5-10mm, suitable for various applications.

Density: Ranges from 0.1-0.6 g/cm³.

Thickness: Common thicknesses range from 5mm to 20mm, with customization available.

Size: Standard sizes range from 500mm x 500mm to 1000mm x 1000mm, with customization available.

Open-cell aluminum foam typically has the following characteristics:

- Interconnected pores: The pores are interconnected, forming a mesh-like structure.

- Good air permeability: Allows gases or liquids to pass freely, suitable for filtration or ventilation.

- Strong sound absorption: Effectively absorbs and dampens sound, widely used in soundproof walls.

- Good heat dissipation: Promotes airflow and improves heat exchange efficiency.

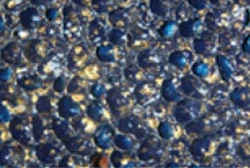

Closed-cell aluminum foam

Closed-cell aluminum foam is a metal foam material with independent, sealed internal pores, offering excellent thermal insulation, low thermal conductivity, low electrical conductivity, and high energy absorption capabilities. It excels in collision energy absorption, making it highly applicable in the automotive industry, particularly for energy absorption and crash protection.

Porosity: Typically ranges from 60% to 90%, affecting thermal insulation performance.

Pore size: Ranges from 0.2mm to 3mm, customizable based on needs.

Density: Ranges from 0.3 to 0.8 g/cm³, offering lightweight and insulating properties.

Thickness: Common thickness ranges from 5mm to 50mm, with customization available.

Size: Common sizes range from 500mm x 500mm to 1000mm x 1000mm.

Key features of closed-cell aluminum foam:

- Strong energy absorption capabilities

- Metal weldability, isotropic properties

- Corrosion-resistant, non-aging

- Low electrical conductivity, low thermal conductivity, low density

- Excellent soundproofing properties

- High energy absorption capacity

- Excellent specific stiffness and shear strength

Different pore size types of aluminum foam

Large pore aluminum foam

Pore size: Typically greater than 3mm.

Features: Larger pores, strong air permeability, poorer sound absorption and thermal insulation, but good structural strength.

Applications: Commonly used in fields requiring large airflow channels, such as ventilation systems, filters, etc.

Medium pore foam aluminum

Pore size: generally between 1mm-3mm.

Characteristics: Balanced performance, suitable for various applications, with good thermal insulation, sound absorption, and heat dissipation properties.

Applications: Widely used in building sound insulation, heat exchangers, radiators, and other fields.

Small pore foam aluminum

Pore size: typically between 0.5mm and 1mm.

Characteristics: Small pores, excellent thermal insulation and sound absorption properties, but relatively poor permeability.

Applications: Suitable for fields requiring efficient thermal insulation and sound absorption, such as building walls, soundproof materials, and noise barriers.

Chalco's specialty aluminum foam

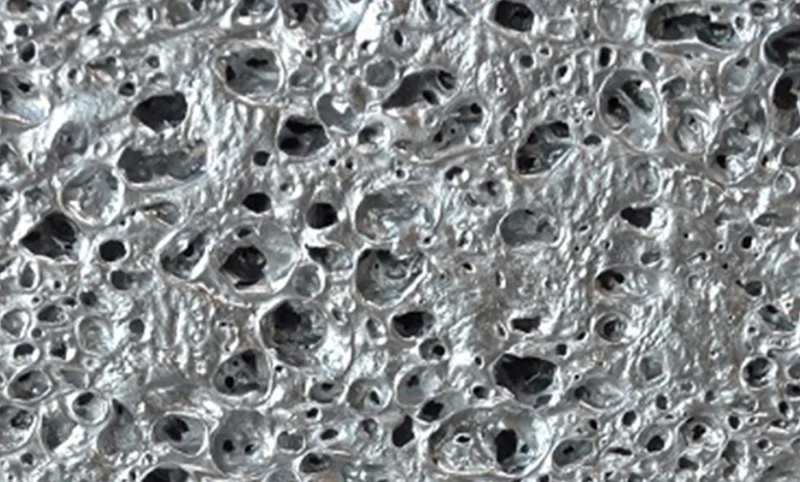

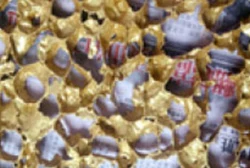

Colored aluminum foam

Aluminum foam can be made into various patterns and coated with durable, radiation-resistant, and acid-alkali-resistant films on the surface, making it a high-quality architectural decorative material.

After being treated with three-proof paint, aluminum foam demonstrates excellent moisture-proof, salt-spray-resistant, and mildew-resistant properties, making it suitable for special environmental requirements while maintaining good waterproof and dielectric performance.

The coating also provides oxidation resistance, thermal stability, and aging resistance, capable of withstanding corrosion from various concentrations of acid, alkali, and salt, and curing at room or low temperatures to form a bright and strongly adhesive paint film.

After special treatment, aluminum foam can withstand high temperatures exceeding 1000°C.

Application areas: Aluminum foam is widely used in interior and exterior decoration, sound absorption and insulation, road noise barriers, equipment noise reduction, energy absorption cushioning, and fireproof and explosion-proof panels, among other fields.

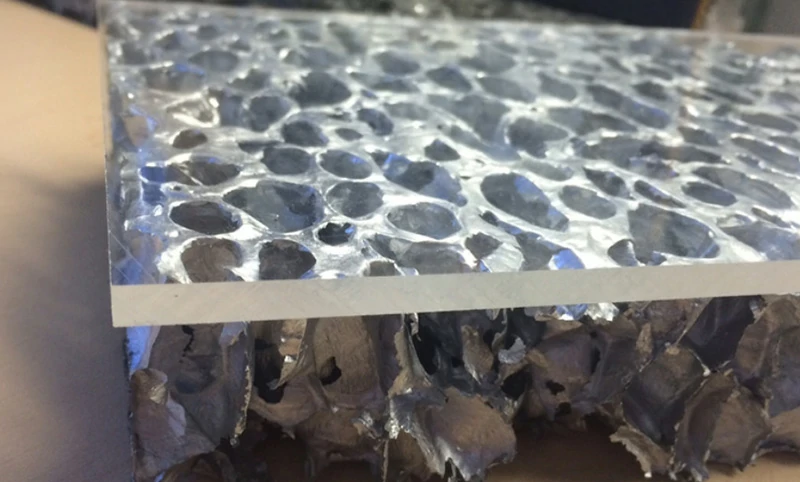

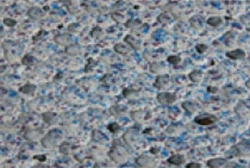

Acrylic composite aluminum foam

Acrylic (PMMA) composite aluminum foam: molded and impregnated; available in metal color, pure white, or pure black. This product can be bent or shaped when softened at around 180°C.

Application fields: Widely used in new decorative panels, applicable to various interior decoration materials, home furnishings, etc.

The performance of Chalco aluminum foam for construction use

Mechanical properties

| Density (g/cm³) | Compressive Strength (MPa) | Bending Strength (MPa) | Energy Absorption (KJ/m³) |

| 0.25~0.30 | 3.0~4.0 | 3.0~5.0 | 1000~2000 |

| 0.30~0.40 | 4.0~7.0 | 5.0~9.0 | 2000~3000 |

| 0.40~0.50 | 7.0~11.5 | 9.0~13.5 | 3000~5000 |

| 0.50~0.60 | 11.5~15.0 | 13.5~18.5 | 5000~7000 |

| 0.60~0.70 | 15.0~19.0 | 18.5~22.0 | 7000~9000 |

| 0.70~0.80 | 19.0~21.5 | 22.0~25.0 | 9000~12000 |

| 0.80~0.85 | 21.5~32.0 | 25.0~36.0 | 12000~15000 |

Weather resistance

Corrosion resistance: After one year of exposure to a marine atmospheric environment, no significant abnormalities were observed. Under accelerated corrosion conditions, the salt spray test showed no issues after 2 years, indicating excellent corrosion resistance. The surface can be treated with a spray coating for further enhanced corrosion protection.

Non-absorbent: The moisture absorption rate of foam aluminum is 0.0%, meaning it does not absorb moisture and will not experience a decrease in acoustic performance due to humidity.

Heat resistance/Non-combustibility: Tested by the National Fireproof Building Materials Quality Supervision and Inspection Center, the combustion performance meets the A1 level.

Thermal insulation performance: Foam aluminum has a thermal conductivity coefficient of 0.25~0.62W/m-K, similar to marble, offering good thermal insulation properties.

Thermal stability: Foam aluminum has a linear expansion coefficient of 19.34*10^-6/°C, comparable to concrete, making it resistant to deformation under heat.

Sound absorption and noise reduction performance

Foam aluminum sound absorption performance: Perforating closed-cell foam aluminum panels can create high sound absorption rate panels. When the open porosity is between 1% and 3%, the sound absorption rate is at its highest. Using the standing wave method, the sound absorption rate is measured to be between 40% and 80% in the 1000Hz to 2000Hz range.

Foam aluminum soundproofing performance: Foam aluminum sandwich panels used for soundproofing boards, 20mm thick, achieve a sound insulation level of 20-40dB, which is 6 times higher than high-density polystyrene.

Electromagnetic shielding performance

| Density (g/cm³) | Frequency (MHz) | Shielding Performance (dB) |

|---|---|---|

| 0.88 | 10 MHz | 110.3 |

| 30.1 MHz | 128.3 | |

| 60.7 MHz | 106.9 | |

| 82 MHz | 104.8 | |

| 100 MHz | 107.1 | |

| 202 MHz | 98.5 | |

| 0.74 | 10 MHz | 110.6 |

| 30.1 MHz | 111.2 | |

| 60.7 MHz | 106.2 | |

| 82 MHz | 94.6 | |

| 100 MHz | 99.8 | |

| 202 MHz | 81.4 | |

| 0.55 | 10 MHz | 98.7 |

| 30.1 MHz | 106.7 | |

| 60.7 MHz | 103.9 | |

| 82 MHz | 82.7 | |

| 100 MHz | 95.4 | |

| 202 MHz | 98.5 | |

| 0.42 | 10 MHz | 111.3 |

| 30.1 MHz | 111.6 | |

| 60.7 MHz | 108.4 | |

| 82 MHz | 94.3 | |

| 100 MHz | 99.5 | |

| 202 MHz | 80.7 | |

| 0.38 | 10 MHz | 110.1 |

| 30.1 MHz | 119.7 | |

| 60.7 MHz | 104.0 | |

| 82 MHz | 97.2 | |

| 100 MHz | 101.9 | |

| 202 MHz | 79.3 |

Chalco aluminum foam applications in the construction field

Exterior wall decoration materials

Aluminum foam is often used as an exterior wall decoration material due to its excellent thermal insulation and fire resistance properties. Its lightweight characteristic helps reduce the structural load of buildings while providing outstanding thermal insulation, enhancing the energy efficiency of the building. The appearance of aluminum foam can also be customized to suit various architectural styles.

Interior partition walls and soundproofing materials

Aluminum foam's high energy absorption characteristics make it an ideal soundproofing material. Inside buildings, it can be used to create soundproof walls, ceilings, and other components to reduce noise pollution. The porous structure of aluminum foam effectively blocks noise transmission, enhancing comfort, particularly in noisy urban environments.

Roof and floor systems

With good thermal insulation properties, aluminum foam is often used in roof and floor systems to effectively isolate the impact of external temperatures on the building interior. It blocks the transfer of heat, maintaining stable indoor temperatures and reducing energy consumption for air conditioning and heating.

Building structural reinforcement

Aluminum foam can be used to reinforce building structures, especially in load-bearing frames and support systems. It enhances the overall stability of the structure and improves seismic performance. Its high strength and lightweight properties allow buildings to bear greater loads while reducing the weight of the structure itself.

Sustainable architecture

As aluminum foam is a recyclable material, it plays an important role in sustainable construction. The use of aluminum foam helps reduce construction waste and lowers the carbon footprint of buildings. Additionally, its corrosion resistance ensures a long service life, further reducing maintenance costs.

Heat exchange systems

Aluminum foam, with its high thermal conductivity and structural characteristics, is commonly used in heat exchange systems. In building HVAC (heating, ventilation, and air conditioning) systems, aluminum foam helps improve heat exchange efficiency, achieving energy-saving effects.

Solar energy systems

Aluminum foam also plays a significant role in solar thermal collectors. Its lightweight and high thermal conductivity make it an ideal backing material for solar collectors, effectively increasing the efficiency of solar energy utilization.

Green roofs

Aluminum foam is crucial in green roofs, providing additional structural support and waterproofing while maintaining the roof's lightweight and thermal insulation properties.

Fire-resistant materials

Due to its high-temperature resistance and fireproof characteristics, aluminum foam is an ideal choice for building fire-resistant materials. When used in fire doors, window frames, and other components, it effectively prevents the spread of fire, enhancing the safety of buildings.

Chalco foam aluminum application case studies

Hall decoration

We used foam aluminum in the design for its novelty, durability, and versatility. Its gray tone creates a striking contrast with the bright white lighting in the elevator lobby, aligning with modern aesthetics. At the same time, foam aluminum, made from aluminum or aluminum alloys, offers both high strength and excellent soundproofing, giving the lobby a distinctive look of modern intelligent architecture.

Exterior wall decoration

Interior wall decoration

What services can Chalco provide for you?

Custom foam aluminum products

Chalco offers custom foam aluminum services, allowing for the customization of different densities, sizes, shapes, and other characteristics according to the specific needs of customers, meeting the requirements of various construction, industrial, or other applications. Thickness, density, porosity, and other properties can be adjusted based on customer specifications.

Material selection and consultation

Chalco's professional team provides material selection and technical consulting services to help customers choose the most suitable foam aluminum products based on their specific application needs. The team can recommend the best density, strength, and other related properties to ensure optimal product performance for the project.

Foam aluminum processing services

In addition to providing foam aluminum materials, Chalco offers processing services such as cutting, drilling, forming, and stamping based on customer needs. Whether for small-batch customization or large-scale production, Chalco ensures precision in processing and product quality.

Surface treatment and enhancement services

Chalco offers various surface treatment techniques such as anodizing, spraying, and electrophoresis to enhance the durability, appearance, and corrosion resistance of foam aluminum. For different applications, Chalco can also provide additional enhancement treatments, such as heat resistance and anti-aging measures.

Quality testing and certification

Chalco conducts rigorous quality testing for each batch of foam aluminum products to ensure compliance with relevant standards. Products undergo multiple quality tests before leaving the factory, including density, compressive strength, bending strength, energy absorption, and more, ensuring each foam aluminum piece meets the project requirements.

Sample provision

Chalco can provide foam aluminum samples based on customer requests for performance and applicability evaluation. Customers can perform further testing on small batch samples to ensure the final batch of products meets their specific needs.

Chalco provides comprehensive support from material selection and processing to after-sales services, ensuring that foam aluminum products meet the practical needs and application requirements of customers. If you have any questions or specific requirements, feel free to contact Chalco for further communication.